Vertical vibration grading crusher and crushing method

A technology of grading and crushing, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of difficult to accurately control the crushing particle size, complex technological process, and easy blockage of the crushing cavity. It is beneficial to the effect of sorting, high crushing precision and low upper limit of crushing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

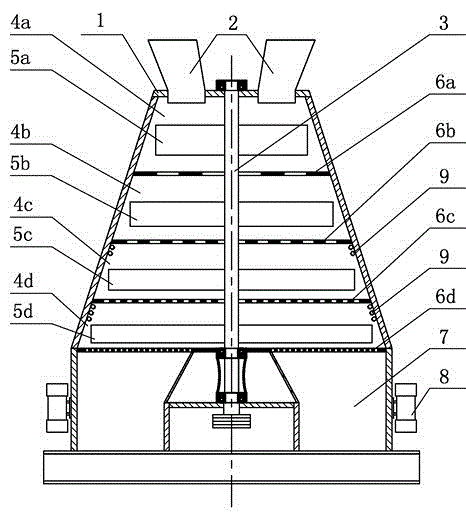

[0021] Such as figure 1 As shown, the vertical vibrating grading crusher of the present invention includes a crusher body 1 with a conical structure, two material guide grooves 2 are symmetrically provided on the top of the crusher body 1, and a cylindrical collecting hopper 7 is provided at the bottom of the body 1. There are four exciters 8 equidistantly arranged on the side of the collecting hopper 7, the inside of the collecting hopper 7 is provided with a power source, the power source is provided with a vertical shaft 3 passing through the body 1, and the body 1 is respectively provided with The first layer of sieve plates 6a, the second layer of sieve plates 6b, the third layer of sieve plates 6c and the fourth layer of sieve plates 6d;

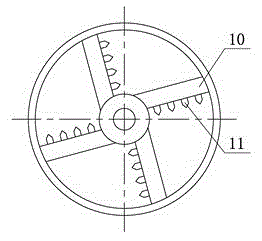

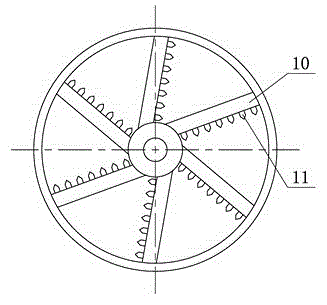

[0022] Such as figure 2 , image 3 , Figure 4 and Figure 5 , the apertures of the four sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com