Device for crushing and grinding uranium ores through assistance of 915MHz pulse microwave irradiation and control method

A pulsed microwave and uranium ore technology, which is applied in the device and regulation field of 915MHz pulsed microwave irradiation assisted grinding and grinding of uranium ore, can solve the problems of difficulty in dissociation of uranium minerals, slow heating, and generation of cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

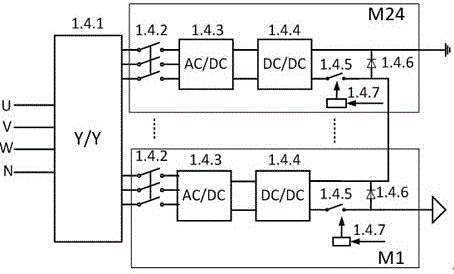

[0036] Example 1 : A CK-611 magnetron was used with a rated power of 20 kW, an anode voltage of 12.5 kV, an anode current of 2.8 A, a filament voltage of 12.5 V, and a current of 115 A. The cooling method is water cooling, and the magnetic field strength is 127 mT~131 mT. The anode high-voltage power supply adopts 24-level superimposed output mode, and the output voltage of each level is -600 V. A total of 21 levels are used. The synchronous modulation method proposed by the present invention is used to generate pulsed microwaves to irradiate volcanic rock-type uranium ore. The repetition frequency is 500 Hz, and the pulse width is 500 Hz. is 500 μS, the duty cycle is 50%, the magnetic field coil current is 2.2A, the effective value of the output anode current is 4 A, and the microwave power is 2.52 times of the rated power.

Embodiment 2

[0037] Example 2 : Use a CK-611 magnetron with a rated power of 20 kW, an anode voltage of 12.5 kV, an anode current of 2.8 A, a filament voltage of 12.5V, and a current of 115A. The cooling method is water cooling, and the magnetic field strength is 127mT~131mT. The anode high-voltage power supply adopts 24-stage superimposed output mode, and the output voltage of each stage is 600 V. The pre-excitation + modulation voltage mode proposed by the present invention is used to generate pulsed microwaves to irradiate volcanic rock-type uranium ore. The pre-excitation voltage is 10.8 kV, the modulation voltage is 1200 V, the repetition frequency is 1000 Hz, the pulse width is 100 μS, the duty cycle is 10%, the effective value of the output anode current is 5.9 A, and the microwave power is 3.54 of the rated power. times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com