Quality improvement and impurity reduction ore dressing method of ferromagnetic minerals

A beneficiation method and strong magnetic technology, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the high cost of smelting and desulfurization, the impact of the economic value of vanadium-titanium iron concentrate, and the restriction of Panxi Issues such as the development and utilization of vanadium-titanium-ferro resources, to achieve excellent overall beneficiation effect, fast beneficiation effect, and huge market economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

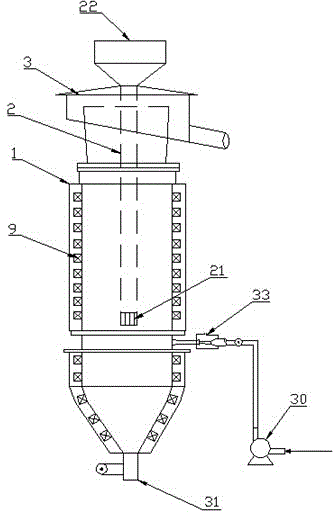

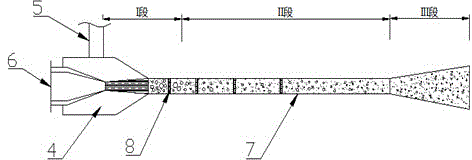

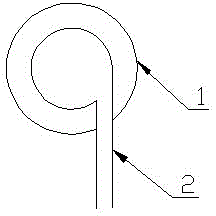

Image

Examples

Embodiment 1

[0043] For a certain magnetite in Xinjiang, the TFe grade is 25.2%. The raw ore is ground in stages until the ore with a particle size of -0.074mm accounts for 50% of the total weight of the raw ore, and the pulp is obtained; the obtained pulp is subjected to cascade weak magnetic separation , to obtain tailings and rough concentrate; the main impurities in the rough concentrate are iron-containing minerals with strong magnetic properties: including iron-containing silicate minerals such as biotite and iron chlorite, and the rough concentrate is selected by a sand mill Grinding until the weight of the ore with a particle size of -0.074mm accounts for 85% of the total weight of the original ore, the pulp is obtained; the pulp is mixed with an inhibitor and a collector, the inhibitor is starch, and the dosage of the agent is 300g / t ·Ore, the collector is ether amine, the dosage is 50g / t ·Ore, the foam stabilizer is ether alcohol, the dosage is 50g / t ·Water, enter the floating agg...

Embodiment 2

[0057] For the complex and difficult-to-select olivine-type vanadium-titanium magnetite in the Panxi area, the TFe grade is 22.5%, and the raw ore is ground in stages until the ore with a particle size of -0.074mm accounts for 55% of the total weight of the raw ore. Obtain ore pulp; carry out cascade weak magnetic separation in the obtained ore pulp to obtain tailings 1 and coarse concentrate; the main impurities in the ferrovanadium coarse concentrate are fayalite and pyrrhotite, and the coarse concentrate is selectively ground by a sand mill ore, after the ore is ground until the weight of the ore with a particle size of -0.074mm accounts for 85% of the total weight of the original ore, the ore pulp is obtained; the ore pulp is mixed with the collector, and the collector is butyl xanthate, and the dosage of the agent is 300g / t·ore , the inhibitor is starch, the dosage is 1000g / t·ore, the foam stabilizer is terpineol oil, the dosage is 10g / t·water, enter the floating agglomera...

Embodiment 3

[0061] For the complex and difficult-to-select vanadium-titanium magnetite in Chengde, Hebei, the grade of TFe is 24.3%, the raw ore is subjected to stage grinding, and after the ore is ground until the ore with a particle size of -0.074mm accounts for 60% of the total weight of the raw ore, the pulp is obtained; the obtained Cascade weak magnetic separation is carried out in the pulp to obtain tailings 1 and rough concentrate; the main impurity in the titanium magnetite rough concentrate is pyrrhotite, and the rough concentrate is selectively ground through a sand mill to After the ore with a particle size of -0.074mm accounts for 90% of the total weight of the original ore, the ore pulp is obtained; the ore pulp is mixed with a collector, the collector is dixanthate, the dosage is 100g / t, the foam stabilizer methyl isobutyl carbinol , the dosage is 100g / t water, enter the floating agglomeration electromagnetic concentrator for selection, control the magnetic field strength of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com