Column separation method and device for high-magnesium-content low-grade phosphate ore

A sorting device, low-grade technology, applied in flotation, solid separation and other directions, can solve the problems of large area of flotation machine, increased maintenance cost and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

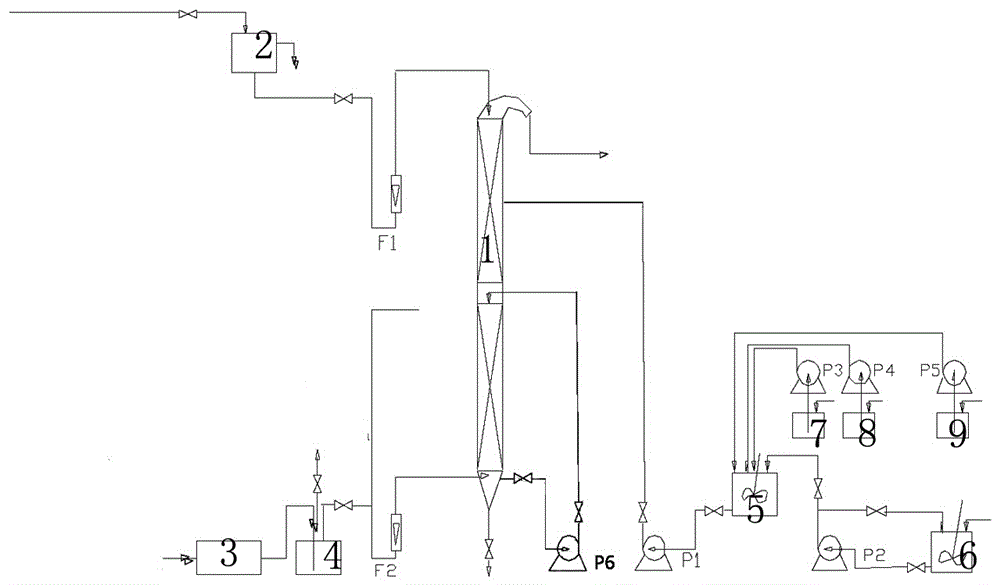

[0019] Experimental Instruments and Equipment

[0020] List of main equipment 1

[0021]

[0022] Experimental content

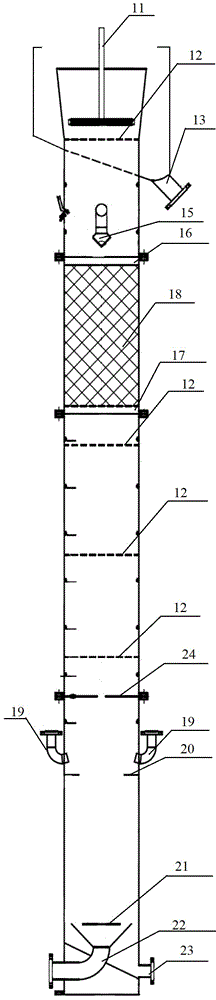

[0023] A dolomitic high-magnesium mixed phosphate ore in Yichang was sorted through a single-stage reverse flotation process using a packed flotation column, and the research on different column flotation process tests was carried out to investigate the amount of ore, the height of the trapping area, the amount of washing water and the pulp The influence of process conditions such as concentration on the separation index.

[0024] A column separation method for high-magnesium and low-grade phosphate rock. Firstly, the phosphate rock raw ore is crushed, ore-ground and classified, and the grinding fineness is controlled to be 150-200 mesh > 85%, and the concentration of the phosphate rock slurry is controlled to be 38%. Then introduce the ore slurry into the mineralization tank, and add reverse flotation reagents to fully mix with the ore slurry, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com