Flotation Technology for Comprehensive Recovery of Gold and Sulfur from Copper Tailings

A technology for recovering gold from copper tailings, applied in the field of flotation process, can solve the problem of not taking into account the comprehensive recovery of residual gold and copper, and achieve the effects of improving the flotation environment, reducing the entrainment rate and improving the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

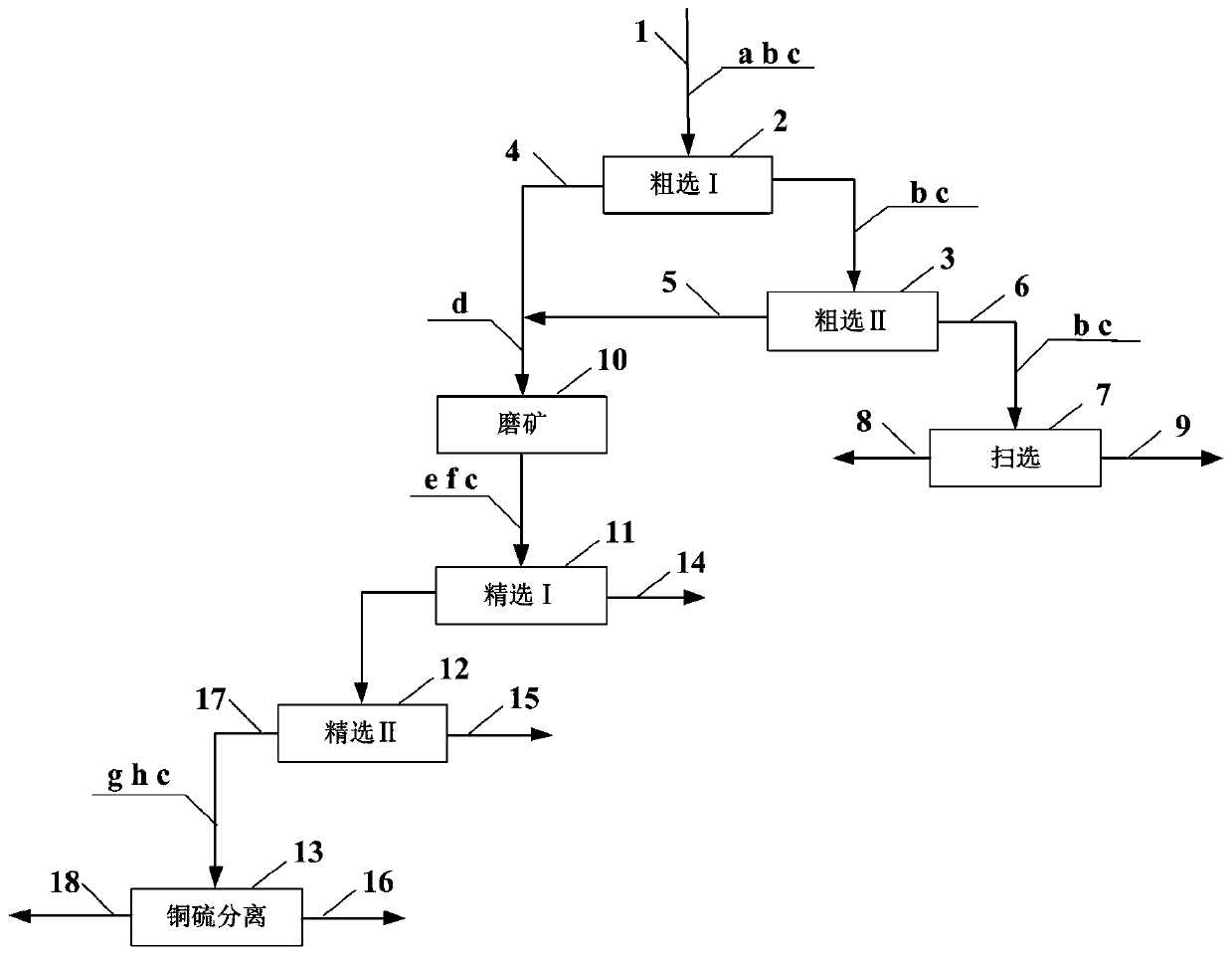

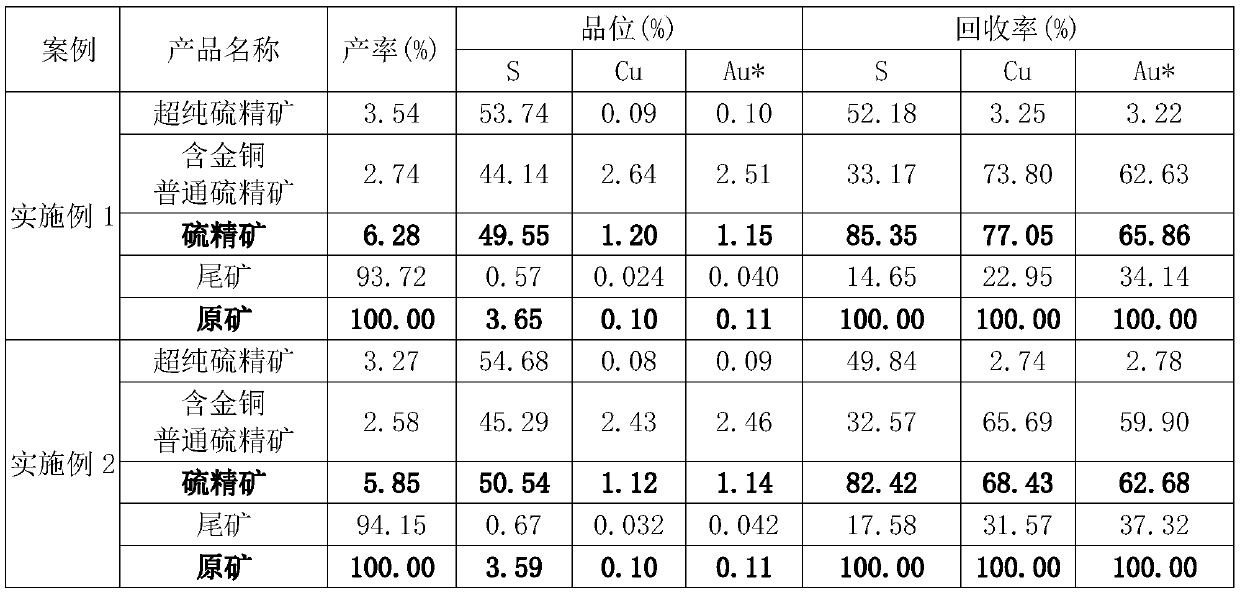

[0037]According to the dry weight of each ton of raw ore, acidic waste water a from the pit is sequentially added to the copper tailings 1 to adjust the pH to 6, the amount of collector b is 15 g / t, and the amount of foaming agent MIBC c is 10 g / t; Separation Ⅰ2, to obtain roughing Ⅰ concentrate 4 and roughing Ⅰ tailings; roughing Ⅰ tailings add 5 g / t of collector ethyl disulfide nitrogen b, foaming agent MIBC c 5 g / t, and carry out roughing Ⅱ 3, Obtain rougher II concentrate 5 and rougher II tailings 6; rougher I concentrate 4 and rougher II concentrate 5 are combined, and at the same time add the regulator ammonium sulfate d with an amount of 200g / t, enter the ball mill for regrinding, and grind The fineness is -0.074mm, accounting for 85.0%; after regrinding, the amount of dispersion inhibitor carboxymethyl cellulose e is 50g / t+the amount of water glass f is 50g / t, and the amount of foaming agent MIBC c is 3g / t. Ⅰ11, get concentrated I concentrate and tailings 14, concentra...

Embodiment 2

[0039] According to the dry weight of each ton of raw ore, acidic waste water a from the pit is added to the copper tailings 1 to adjust the pH to 7, the amount of the collector ethyl disulfide nitrogen b is 20 g / t, and the foaming agent MIBC c is used in an amount of 20 g / t; Separation Ⅰ2, obtain roughing Ⅰ concentrate 4 and roughing Ⅰ tailings; roughing Ⅰ tailings are added with the amount of 10g / t of collector ethyl disulfide nitrogen b, and the amount of foaming agent MIBC c 10g / t, and carry out roughing Ⅱ, Obtain rougher II concentrate 5 and rougher II tailings 6; rougher I concentrate 4 and rougher II concentrate 5 are combined, and at the same time add the regulator ammonium sulfate d with an amount of 300g / t, enter the ball mill for regrinding, and grind The fineness is -0.074mm, accounting for 90.0%; after regrinding, the amount of dispersion inhibitor carboxymethyl cellulose e is 100g / t, the amount of water glass f is 100g / t, and the amount of foaming agent MIBC c is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com