Separating reacting pulverizer

A pulverizer and reaction technology, used in centrifuges, fuel supply, block/powder fuel preparation, etc., can solve the problems of easy aging of catalysts, low efficiency of pulverizing powder, and unclean selection, and improve equipment Operational efficiency, flue gas emissions are completely environmentally friendly, and the effect of resource recycling is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

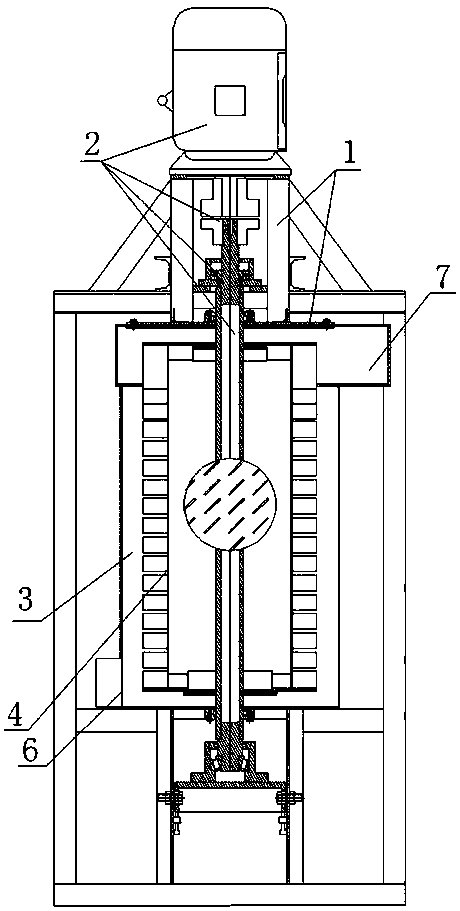

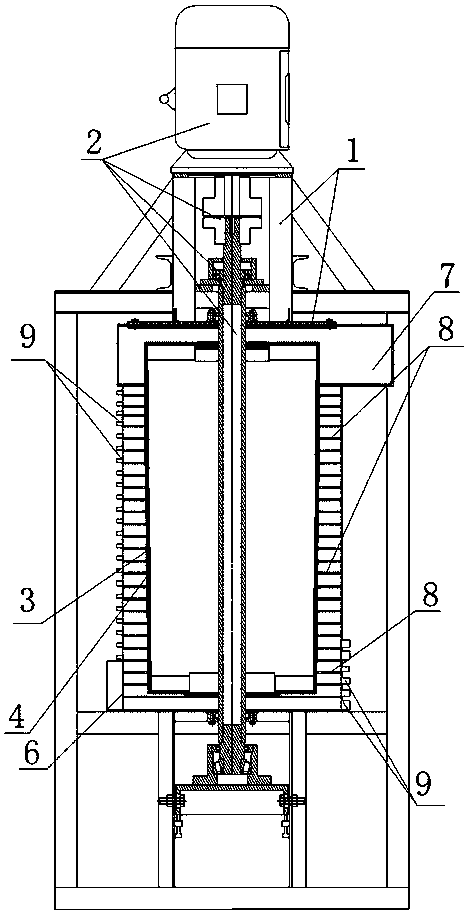

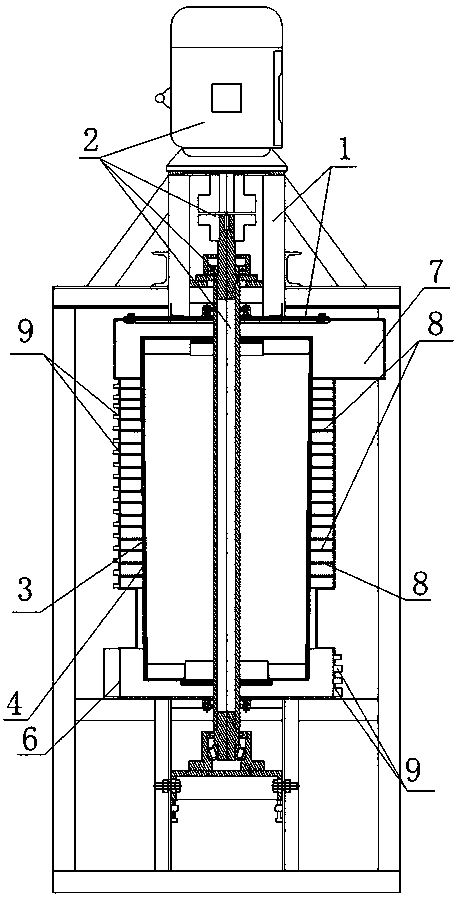

[0065] The main structure of the present invention includes a housing 1 and a transmission device 2, the transmission device 2 is arranged on the housing 1, the housing cavity 3 is arranged in the housing 1, the vortex wheel 4 is arranged in the housing cavity 3, and the vortex wheel 4 is arranged on the outer circumference and the axial direction. A plurality of fluid actuating devices 5 are arranged on each of them, the transmission device 2 is connected with the vortex wheel 4 , the casing chamber inlet 6 is arranged at one end of the casing chamber 3 , and the casing chamber outlet 7 is arranged at the other end of the casing chamber 3 .

[0066] The scope of the casing 1 includes a base, a bracket, a pipe, a casing, and a power device, and each part can be collectively referred to as a casing. The housing 1 can also be integrated with the power device to form an integral housing. The present invention can select different materials to manufacture according to needs, can u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com