Screening device for paper making

A screening and paper technology, applied in textiles and papermaking, solid separation, fiber raw material processing, etc., can solve the problems of reduced inflow of papermaking raw materials, heightened height, and larger equipment, so as to improve the selection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

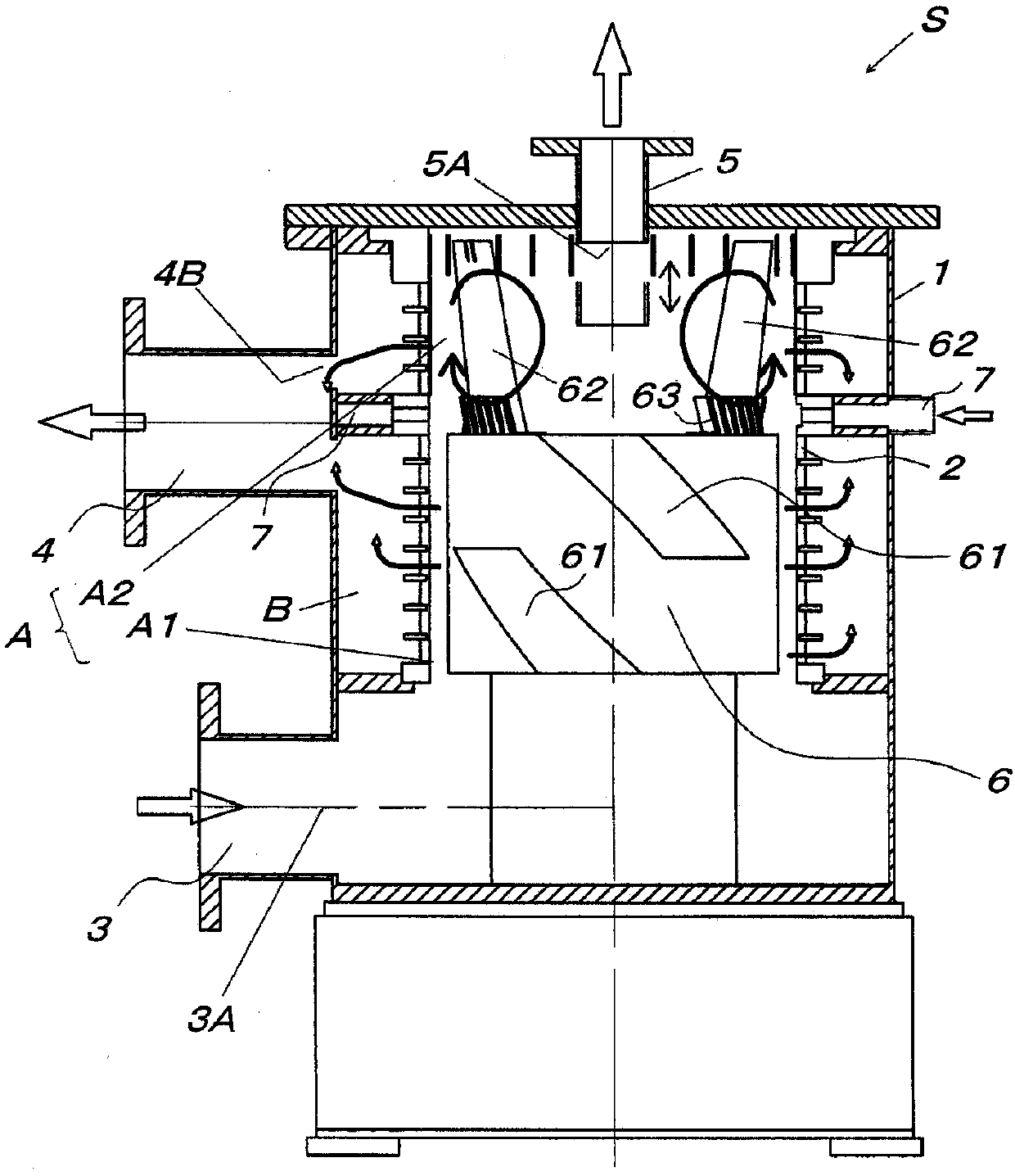

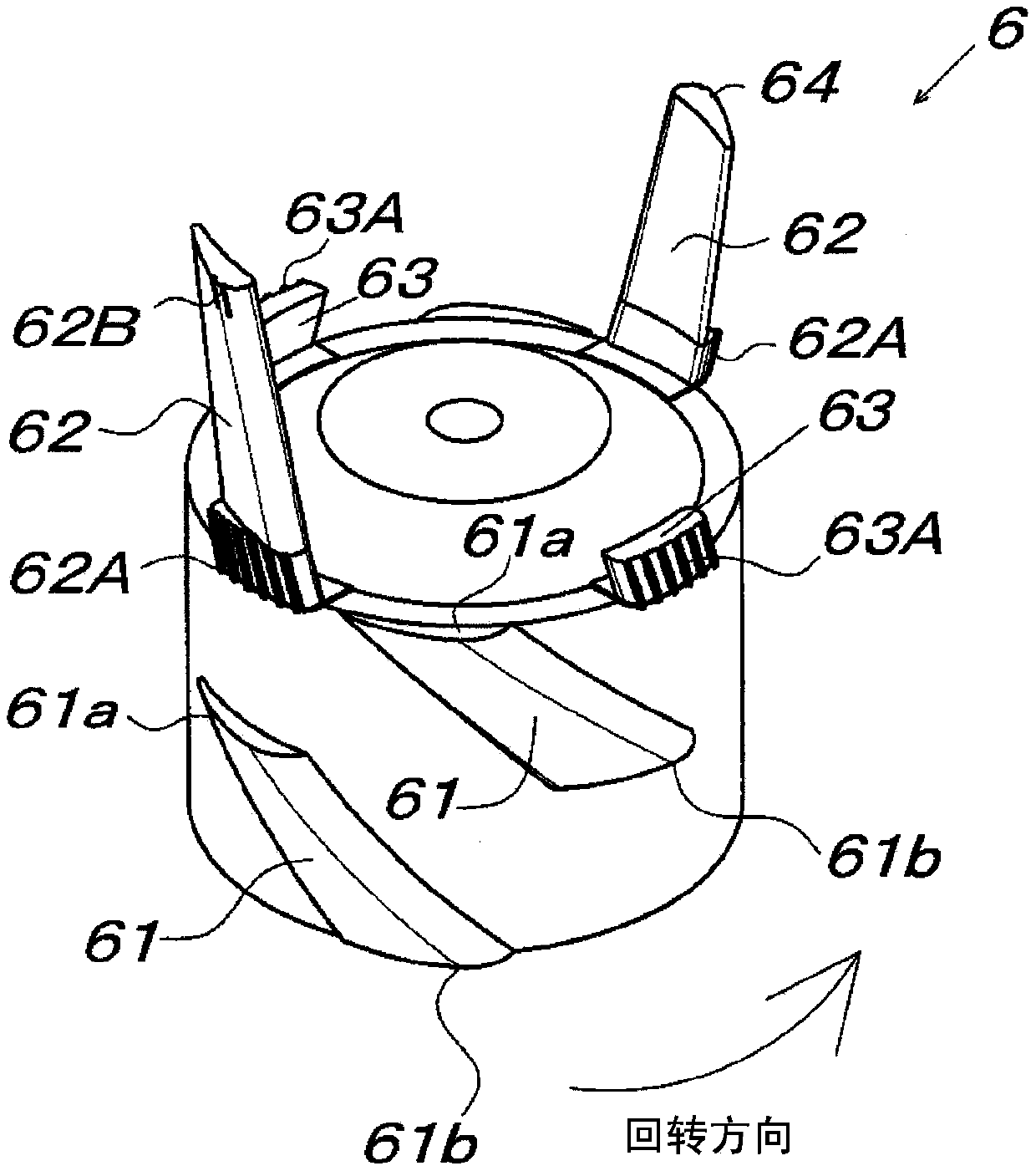

[0045] refer to Figure 1 to Figure 3 A paper-making screening device according to an embodiment of the present invention will be described.

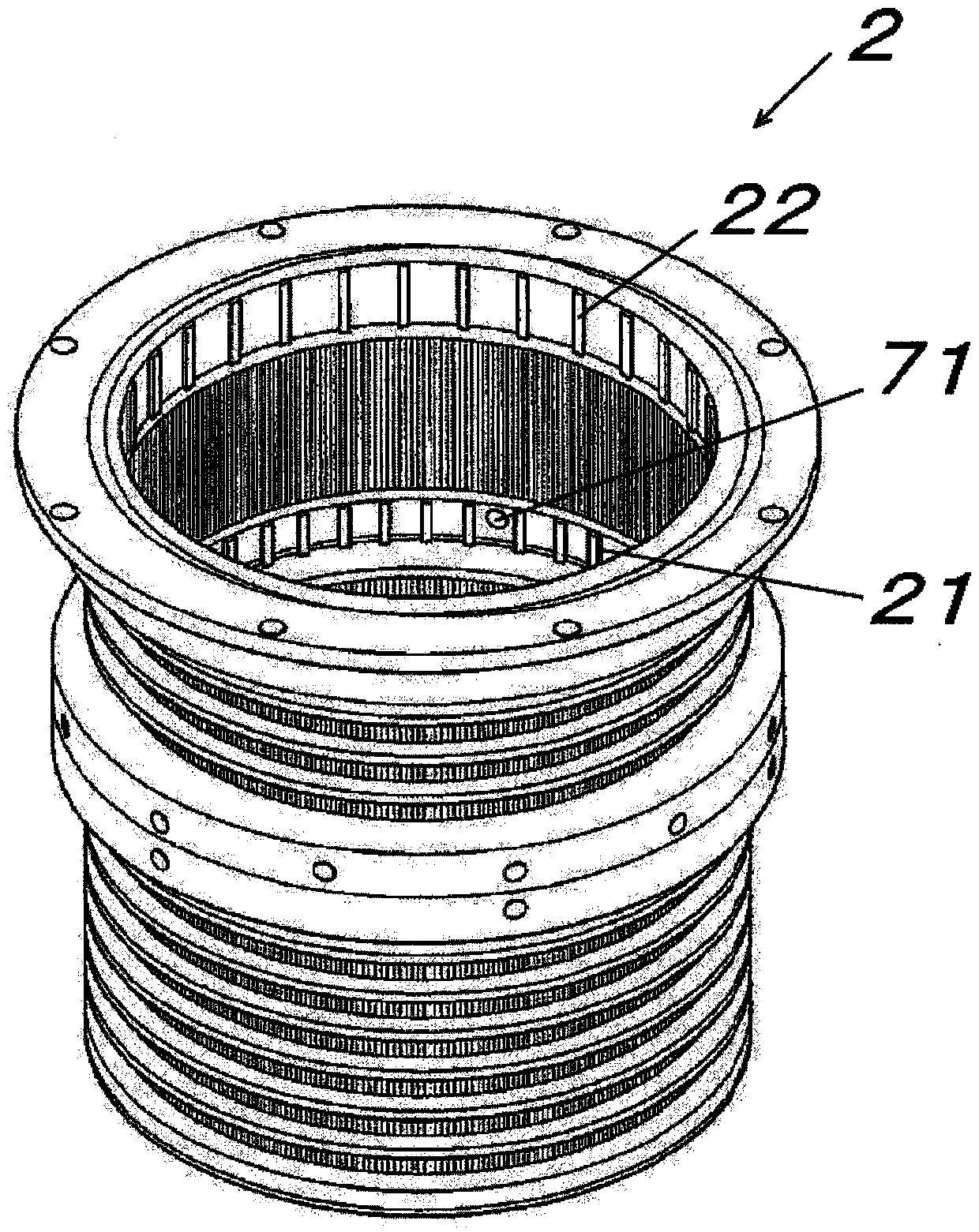

[0046] exist figure 1 Among them, the reference symbol S is a paper-making screening device, and the paper-making screening device S is to raise the cylindrical filter 2 in the casing 1 to separate foreign matter from the paper-making raw materials to refine the paper-making raw materials. device.

[0047] The casing 1 is divided into a first chamber A and a second chamber B by a cylindrical screen filter 2 .

[0048] A papermaking raw material supply path 3 is connected to the casing 1 . The papermaking raw material supply passage 3 supplies the papermaking raw material to the first chamber A so that the opening end 3A faces the first chamber A.

[0049] In addition, the casing 1 is connected to a selected papermaking raw material discharge passage 4 . The selected papermaking stock discharge passage 4 makes the opening end 4B face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com