Closed circuit ore grinding classification method

A classification method, closed-circuit grinding technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of production stability, production cost, processing capacity, short life of large-scale screening equipment, The small production capacity of the screening equipment can achieve the effect of reducing anti-enrichment, large production capacity and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: A tin ore dressing plant in Yunnan uses a φ2100×3000 grinding machine and a φ1500 double spiral classifier for closed-circuit grinding and classification, with a discharge particle size of 0.3mm, a grinding fineness of -200 mesh accounting for 60%, and a classification efficiency of 46 %, the -200 mesh entrainment in the returned sand is about 8%, and the entrainment of fine particles in the returned sand leads to low classification efficiency. The present invention utilizes existing equipment to transform the grinding and classification system.

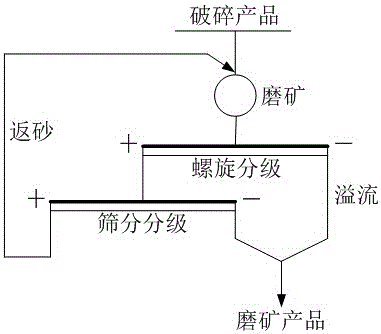

[0024] The modified grinding and grading process is as follows: a spiral classifier and a vibrating screen classifier are combined to process the ore slurry from the mill. First, the slurry discharged from the mill is fed to the spiral classifier, and then the coarse particles produced by the spiral classifier are returned The sand is fed to the vibrating screen, which is placed on the side of the spiral classifier, and...

Embodiment 2

[0027] Example 2: A concentrator that processes 1500 tons of copper ore each day in Yunnan uses a φ2700×3600 grinding machine and a φ2000 double spiral classifier for closed-circuit grinding and classification, with a discharge particle size of 0.3mm and a grinding fineness of -200 mesh accounting for 60%. The classification efficiency is 45%, and about 12% is entrained in -200 mesh in the returned sand. The entrainment of fine particles in the returned sand leads to low classification efficiency. The classification method and device used are the same as in Example 1.

[0028] The size of the vibrating screen is 1100×800×900mm. The upper sieve of the vibrating screen adopts a 6mm urethane sieve plate, and the lower layer adopts a wear-resistant stainless steel sieve with an aperture of 0.35mm. The vibration frequency is 1500 times / min. The return sand discharge port of the spiral classifier is higher than the feed port of the vibrating screen, and the returned sand flows into the ...

Embodiment 3

[0030] Example 3: The designed production capacity of a concentrator is 1000t / d, and one MQG2740 grid-type ball mill is used for grinding, and one FLGT-2000 high weir spiral classifier is used for grading. The discharge particle size is 0.3mm. The fineness of -200 mesh accounts for 60%, the classification efficiency is 62%, and the entrainment of -200 mesh in the returned sand is about 10%. The present invention utilizes existing equipment to transform the grinding and classification system, and the classification method and device used are the same as in Example 1.

[0031] The size of the vibrating screen is 1000×750×900mm. The upper screen of the vibrating screen adopts a polyurethane sieve plate with a hole diameter of 4mm, and the lower layer adopts a wear-resistant stainless steel screen with a hole diameter of 0.3mm. The vibration frequency is 1800 times / min. The return sand discharge port of the spiral classifier is higher than the feed port of the vibrating screen, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com