Boron carbide accurate grinding aid and use method thereof

A grinding aid, boron carbide technology, applied in chemical instruments and methods, other chemical processes, grain processing, etc., can solve problems such as lack of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

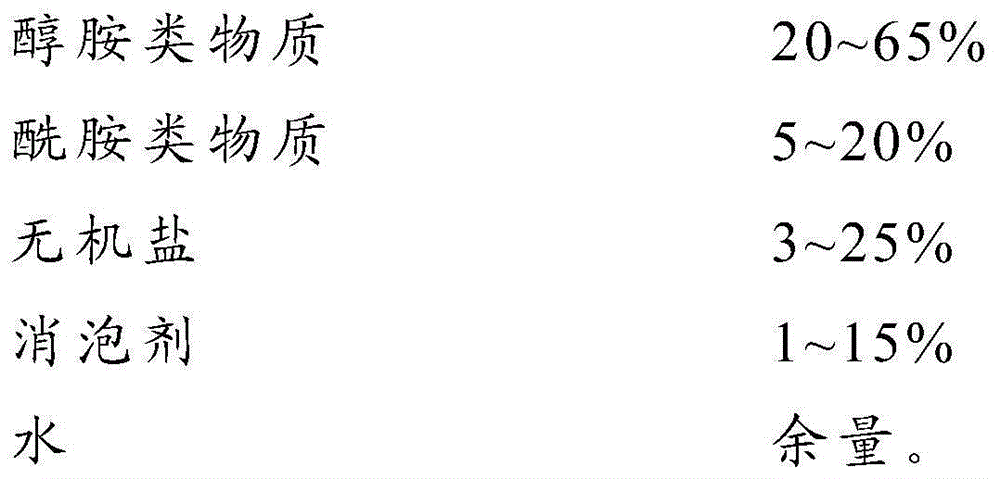

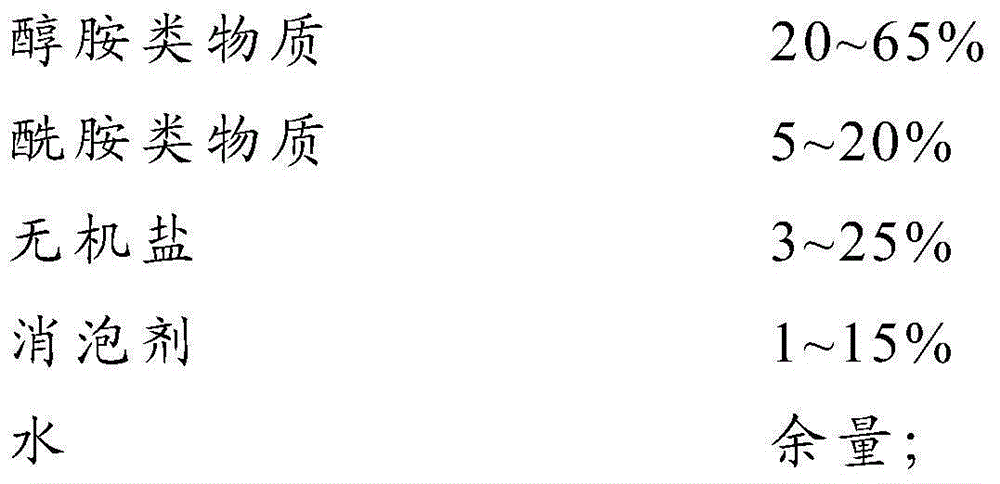

Method used

Image

Examples

Embodiment 1

[0064] Mix and stir 50kg of triisopropanolamine, 10kg of polyacrylamide, 10kg of calcium metaphosphate, 5kg of tributyl phosphate and 25kg of water to prepare a grinding aid.

[0065] Put the boron carbide raw material (D50 particle size is 19.43μm) into the ball mill according to the material ball water ratio = 1:2.5:0.5, wherein, the material refers to the boron carbide raw material, the ball refers to the abrasive ball in the ball mill, and the water is pre-added when starting the ball mill Water, in this embodiment, 100 kg of boron carbide raw material, 250 kg of abrasive balls, and 50 kg of water, that is, the solid content is 66.7%, and the target ball milling D50 particle size is 3.6 μm.

[0066] After the above mixture was ball milled for 8 hours, the grinding aid prepared in the above steps was added in an amount of 0.35% relative to the weight of the boron carbide powder, that is, 350 g.

[0067] During the ball milling process, due to the heat generated, a large amo...

Embodiment 2

[0069] Mix and stir 55kg of triisopropanolamine, 10kg of polyacrylamide, 12kg of sodium hexametaphosphate, 8kg of diethylethanol and 15kg of water to prepare a grinding aid.

[0070] Put the boron carbide raw material (D50 particle size is 20.27μm) into the ball mill according to the material ball water ratio = 1:2.8:0.6, wherein, the material refers to the boron carbide raw material, the ball refers to the abrasive ball in the ball mill, and the water is pre-added when starting the ball mill Water, in this embodiment, 100kg of boron carbide raw material, 280kg of abrasive balls, 60kg of water, that is, the solid content is 62.5%, and the target ball mill particle size D50 is 3.0 μm.

[0071] After the above mixture was ball milled for 6 hours, the grinding aid prepared in the above steps was added in an amount of 0.6% relative to the weight of the boron carbide powder, that is, 600 g.

[0072] During the ball milling process, due to the heat generated, a large amount of water...

Embodiment 3

[0074] Mix and stir 55kg of triethanolamine, 10kg of succinimide, 12kg of aluminum metaphosphate, 8kg of polyoxypropylene polyoxyethylene glyceryl ether and 15kg of water to prepare a grinding aid.

[0075] Put the boron carbide raw material (D50 particle size is 20.27μm) and the above-mentioned grinding aid into the ball mill according to the ratio of material, ball, water and grinding aid = 1:2.8:0.6:0.6%, wherein, the material refers to The boron carbide raw material, the ball refers to the abrasive ball in the ball mill, and the water is the water pre-added when starting the ball mill. In this embodiment, the boron carbide raw material is 100kg, the abrasive ball is 280kg, the water is 60kg, and the grinding aid is 600g, that is, the solid content is 62.5 %, the target ball mill particle size D50 is 3.0 μm.

[0076] During the ball milling process, due to the heat generated, a large amount of water evaporates. Therefore, it is necessary to properly replenish water to ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com