Ore dressing technology for comprehensively recovering lean and fine wiikite

A technology of miscellaneous niobium ore and process is applied in the field of beneficiation process for comprehensive recovery of lean and fine miscellaneous niobium ore, which can solve the problem of single recovery, and achieve the effect of improving grade and recovery rate and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Table 1-1: Multi-element analysis results of a niobium-zirconium polymetallic ore A

[0023] the element

Ta 2 o 5

Nb 2 o 5

ZrO 2

mn

Au(g / t)

Th

Content (wt%)

0.0035

0.065

0.334

0.44

0.08

0.009

the element

TiO 2

sn

P

S

A1 2 o 3

U

Content (wt%)

0.33

0.034

0.01

0.43

14.46

0.004

the element

K 2 o

Na 2 o

SiO 2

CaO

MgO

Content (wt%)

3.69

0.26

68.41

0.018

0.99

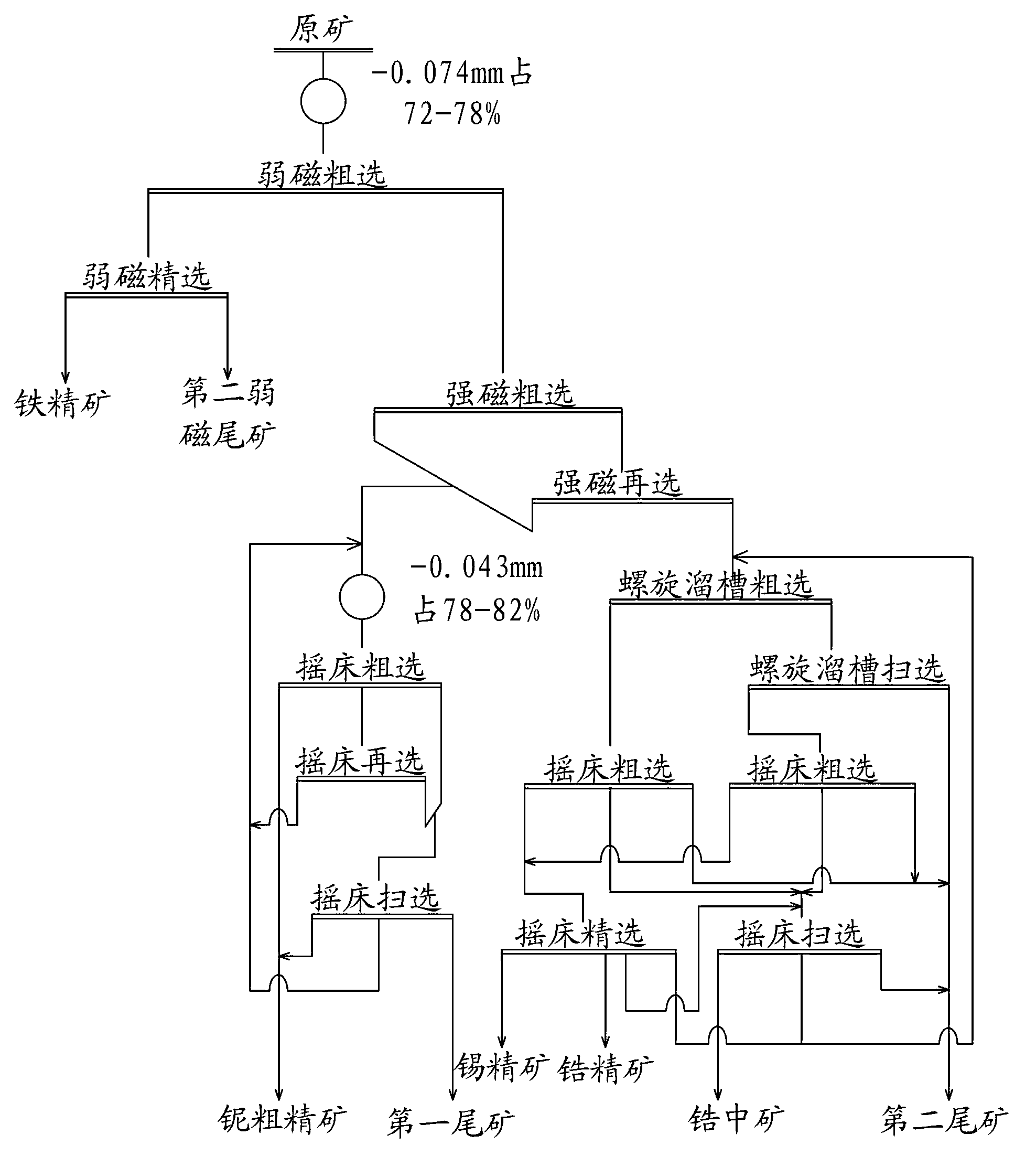

[0024] The valuable elements that can be recovered in a niobium-zirconium polymetallic ore A mainly include niobium, zirconium, and tin. The grades of niobium and tin are low, and the zirconium content is at the cut-off grade. Phase analysis shows that this niobium-zirconium polymetallic raw ore A contains niobite, ferrotitanium-niobium-yttrium ore, uranium-lead pyroch...

Embodiment 2

[0035] Table 2: Multi-element analysis results of a niobium-zirconium polymetallic ore B

[0036] the element

Nb 2 o 5

ZrO 2

SnO 2

Content (%)

0.105

0.654

0.041

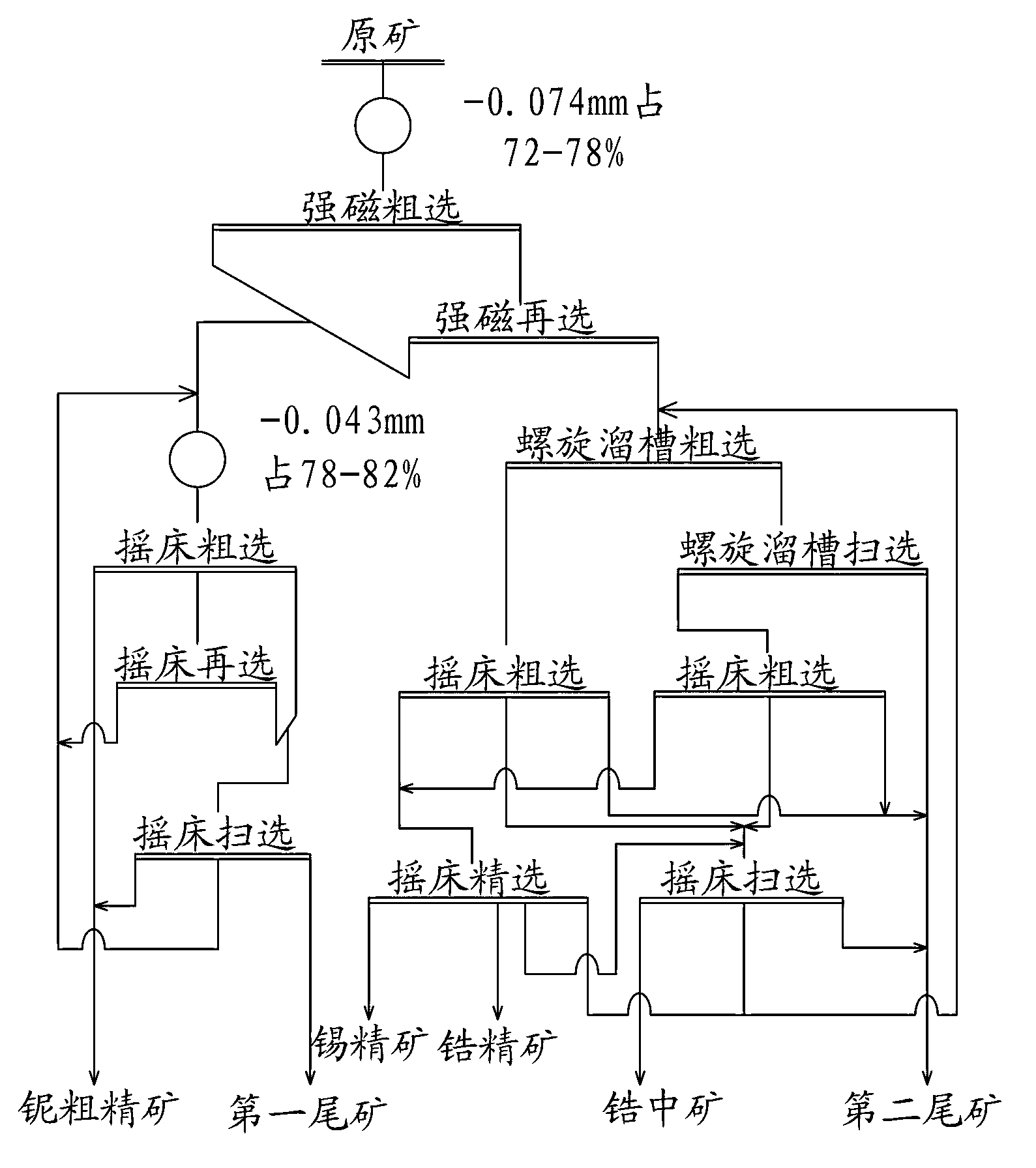

[0037] The recoverable valuable elements in a niobium-zirconium polymetallic ore B mainly include niobium, zirconium, and tin. The chemical analysis results are shown in Table 2. Such as figure 1 Shown, by the process of the present invention, niobium-zirconium polymetallic raw ore B (hereinafter referred to as raw ore) is beneficiated according to the following steps:

[0038] 1) After crushing the raw ore, carry out a stage of ore grinding, so that the particle size is -0.074mm, which accounts for 72%-78%, and water is added to form an ore slurry with a concentration of 30% by weight;

[0039] 2) The ore pulp is subjected to strong magnetic roughing in a vertical ring high gradient magnetic separator with a magnetic field strength of 8000 Oersted to obt...

Embodiment 3

[0043] Table 3: C multi-element analysis results of a niobium-zirconium polymetallic ore

[0044] Yuan Suo

Nb 2 o 5

ZrO 2

SnO 2

Content (%)

0.038

0.224

0.019

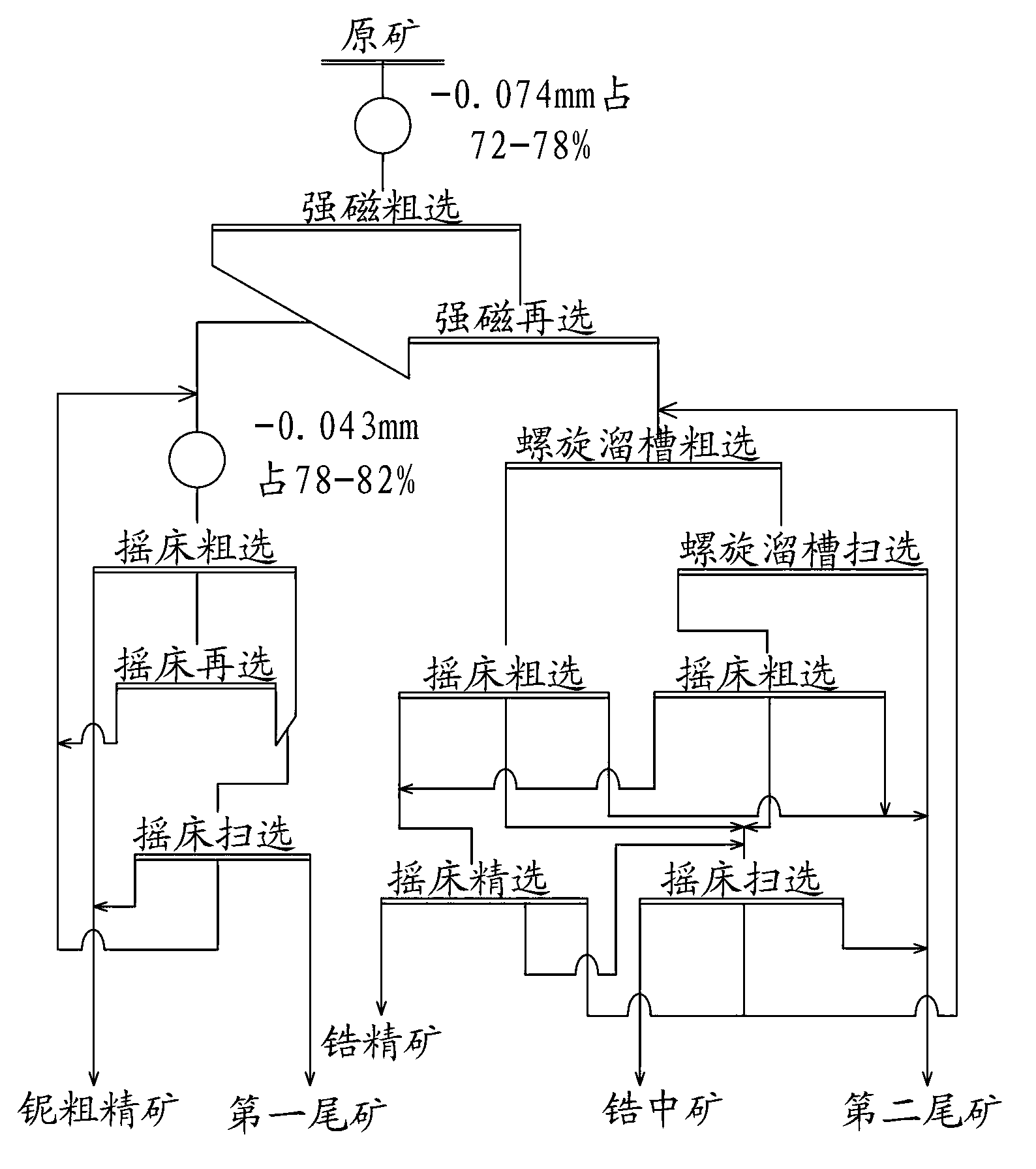

[0045] The recoverable valuable elements in a niobium-zirconium polymetallic ore C mainly include niobium, zirconium, and tin. The chemical analysis results are shown in Table 3.

[0046] Such as figure 1 Shown, by the process of the present invention, niobium-zirconium polymetallic raw ore C (hereinafter referred to as raw ore) is ore-dressed according to the following steps:

[0047] 1) After the raw ore is crushed, carry out a stage of ore grinding, so that the particle size is -0.074mm, which accounts for 72-78%, and water is added to form an ore slurry with a concentration of 35% by weight;

[0048] 2) The ore pulp is subjected to strong magnetic roughing in a vertical ring high gradient magnetic separator with a magnetic field strength of 9000 Oersted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com