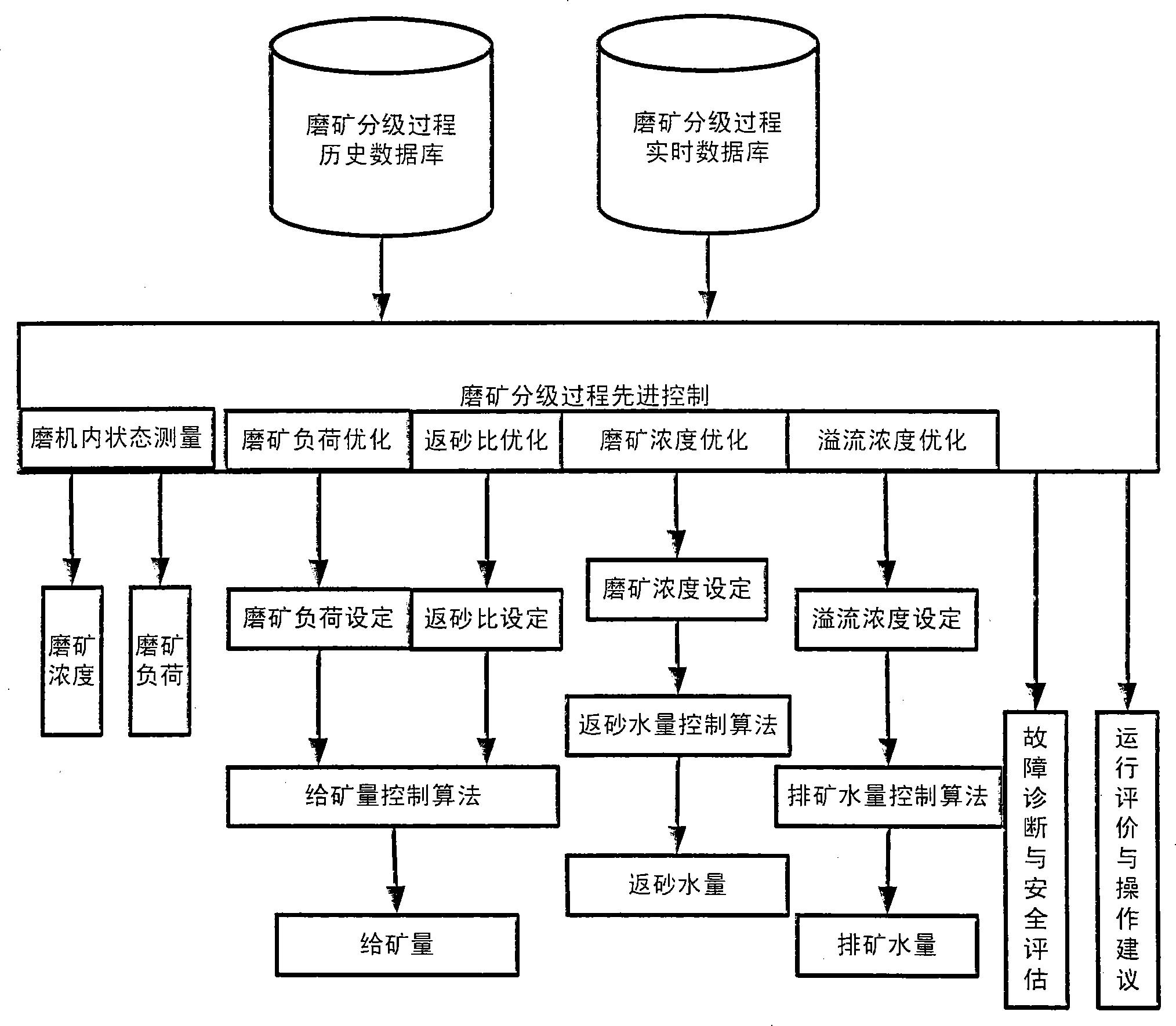

Optimization control method for grind grading process

A process optimization and control method technology, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of low production efficiency, high energy consumption, uneven product quality, etc., and achieve the reduction of labor intensity, Low energy consumption and the effect of improving enterprise management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

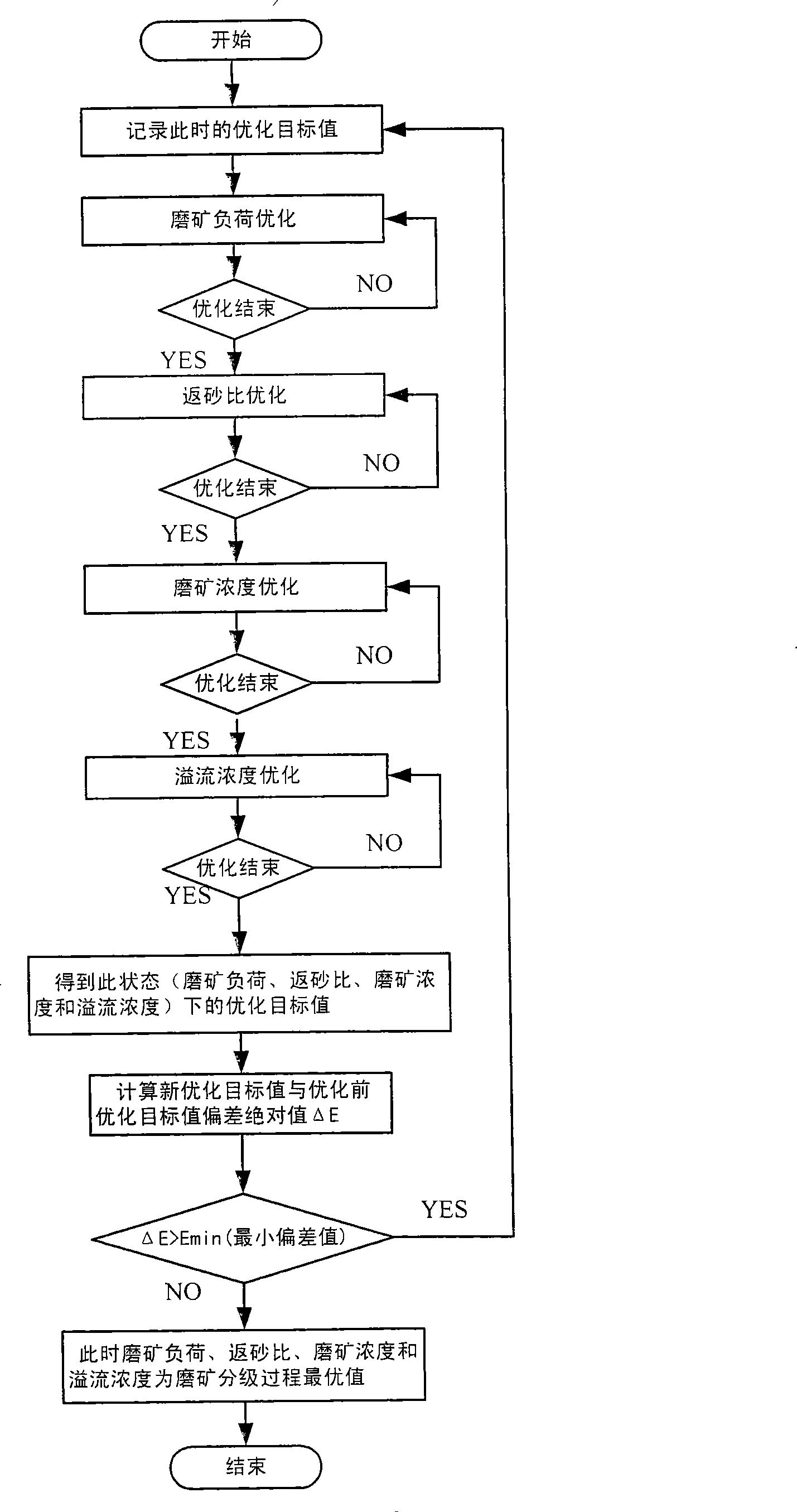

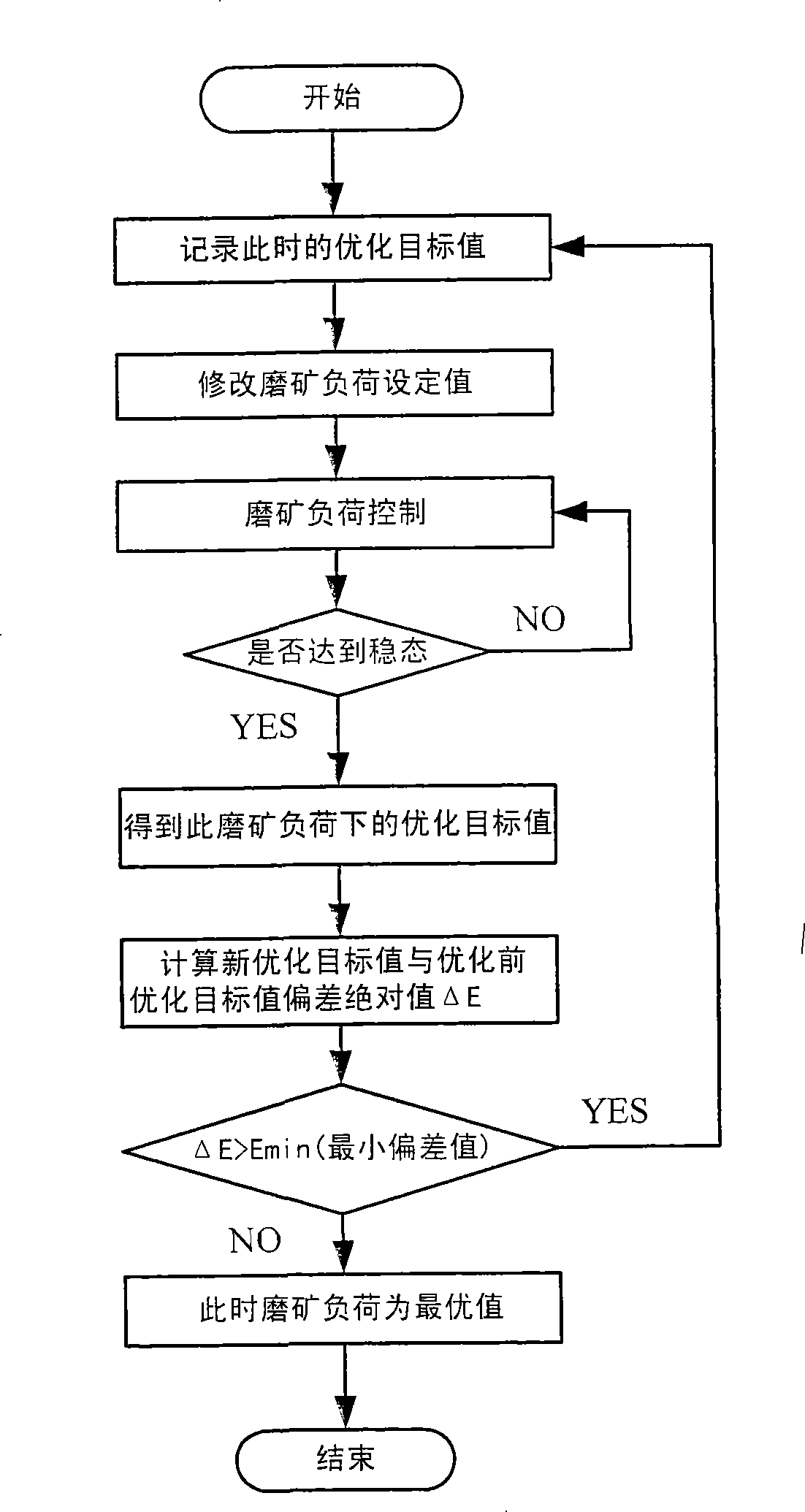

Method used

Image

Examples

Embodiment

[0071] The grinding machine of an iron ore dressing plant, the specification of the grinding machine is φ3200×4500, the cylinder has a constant speed of 18.5r / min, the loading capacity of steel balls is 73T, the rated power is 1000kw, the rated current is 38A, the set output is 52t / h, the choice of feeding JGC-40I belt weighing feeder, the maximum feeding rate is 100t / h, the screw classifier model is FG-7, the screw speed is 3.5r / min, the sand return rate is 100-445t / h, and the overflow rate is 31- 165t / h.

[0072] The control system selects S7-300PLC, and the host computer selects industrial control computer.

[0073] Firstly, the advanced control module obtains the historical data and real-time data of the grinding and grading process. The data includes: feeding amount (1-100t / h), motor current (0-50A), motor power (0-1200kw), vibration measuring points (4 -20mA), noise measuring point (4-20mA), sand-returning water flow rate (0-300t / h), sand-returning amount (0-280t / h), sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com