A device for removing organic impurities in by-product sodium chloride salt in a chlorination process

A technology of sodium chloride and chlorination, applied in the field of organic impurity removal device, can solve the problems of single treatment, bonding of carbonization equipment, low impurity content, etc., achieves broad market prospects, high thermal efficiency utilization, and solves the effect of nozzle blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

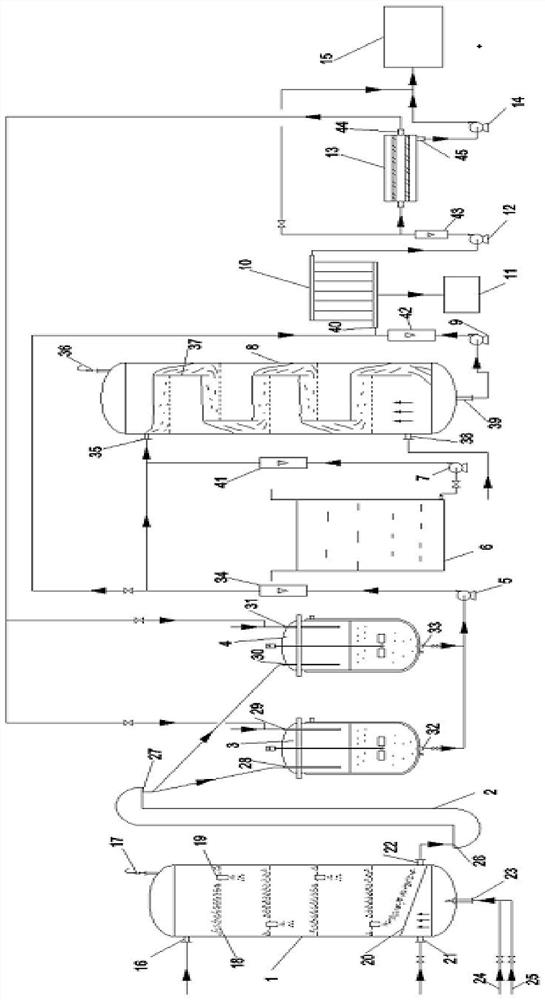

[0028] The present invention will be further described in detail by means of the accompanying drawings and specific embodiments.

[0029] Such as figure 1 , the components in the figure are marked as:

[0030] 1. High temperature oxidation reactor; 2. Bucket elevator; 3. Dissolving kettle A; 4. Dissolving kettle B; 5. Centrifugal pump A; 6. Oxidant storage tank; 7. Centrifugal pump B; 8. Liquid phase deep oxidation Tower; 9. Booster pump A; 10. Liquid-solid filter; 11. Solid slag tank; 12. Booster pump B; 13. Fine filter; 14. Delivery pump; 15. Ionic membrane caustic soda industrial device; 16. Salt powder inlet; 17. Flue gas discharge pipe; 18. Sieve plate; 19. Powder overflow downpipe; 20. Gas distribution plate; 21. Air inlet; 22. Salt powder outlet; 23. Burner; 24 .Air inlet pipe; 25. Gas inlet pipe; 26. Bucket lift inlet; 27. Bucket lift outlet; 28. Powder inlet A; 29. Water inlet A; 30. Powder inlet B; 31 .Water inlet B; 32. Salt solution outlet A; 33. Salt solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com