Double-helix pyrolysis reactor based on pyrolytic carbon internal circulation enhanced heat transfer

A pyrolysis reactor and enhanced heat transfer technology, applied in the direction of combined direct and indirect heating dry distillation, special form of dry distillation, biofuels, etc., can solve the problems of poor heat transfer performance, difficult to scale up, etc., to promote mixing, change production The effect of high efficiency and large biomass treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

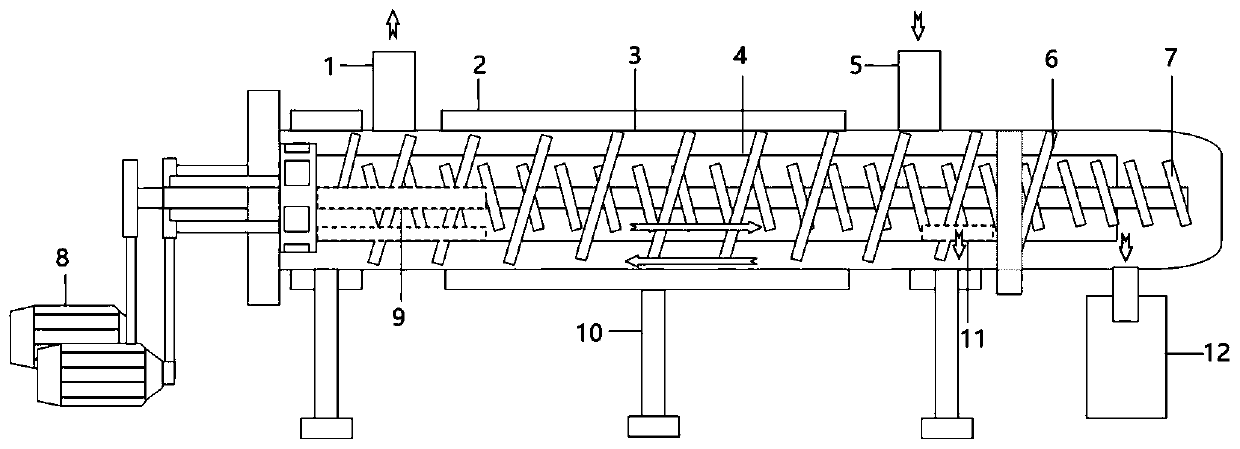

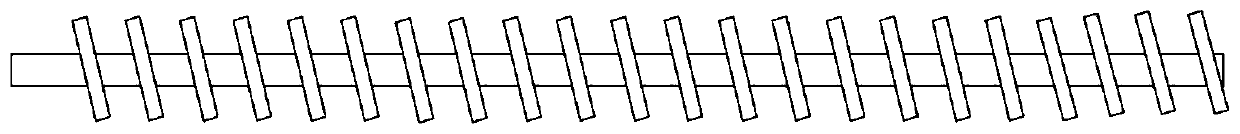

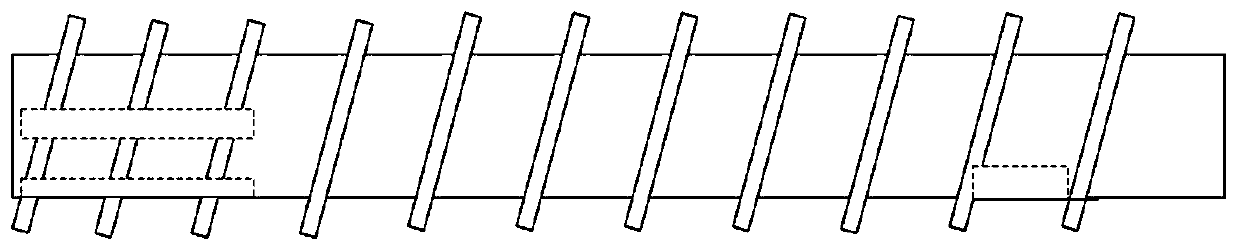

[0025] Such as figure 1 As shown, a double-helix pyrolysis reactor based on internal circulation of pyrolytic carbon to enhance heat transfer in the present invention has a horizontal cylindrical outer spiral drum 3 as the main body, and a pyrolysis gas outlet is provided at the upper left end of the outer spiral drum 3 1. A feed inlet 5 is provided at the upper right end of the outer spiral drum 3, a pyrolytic carbon collection box 12 is provided at the lower end of the right part, an electric heating device 2 is installed outside the outer spiral drum 3, and three The support frame 10 supports the entire outer spiral drum 3; inside the outer spiral drum 3, there are two coaxial rotating screws with opposite blade helical directions, that is, the outer screw 6 and the inner screw 7 are arranged through the outer spiral drum 3 from left to right, wherein the inner scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com