A garbage pyrolysis device and method

A pyrolysis and waste technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of being susceptible to seasons, cities, large moisture content of waste, and large fluctuation range, and achieve wide processing capacity adjustment range, group size, etc. The effect of strong adaptability to changes and strong water adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

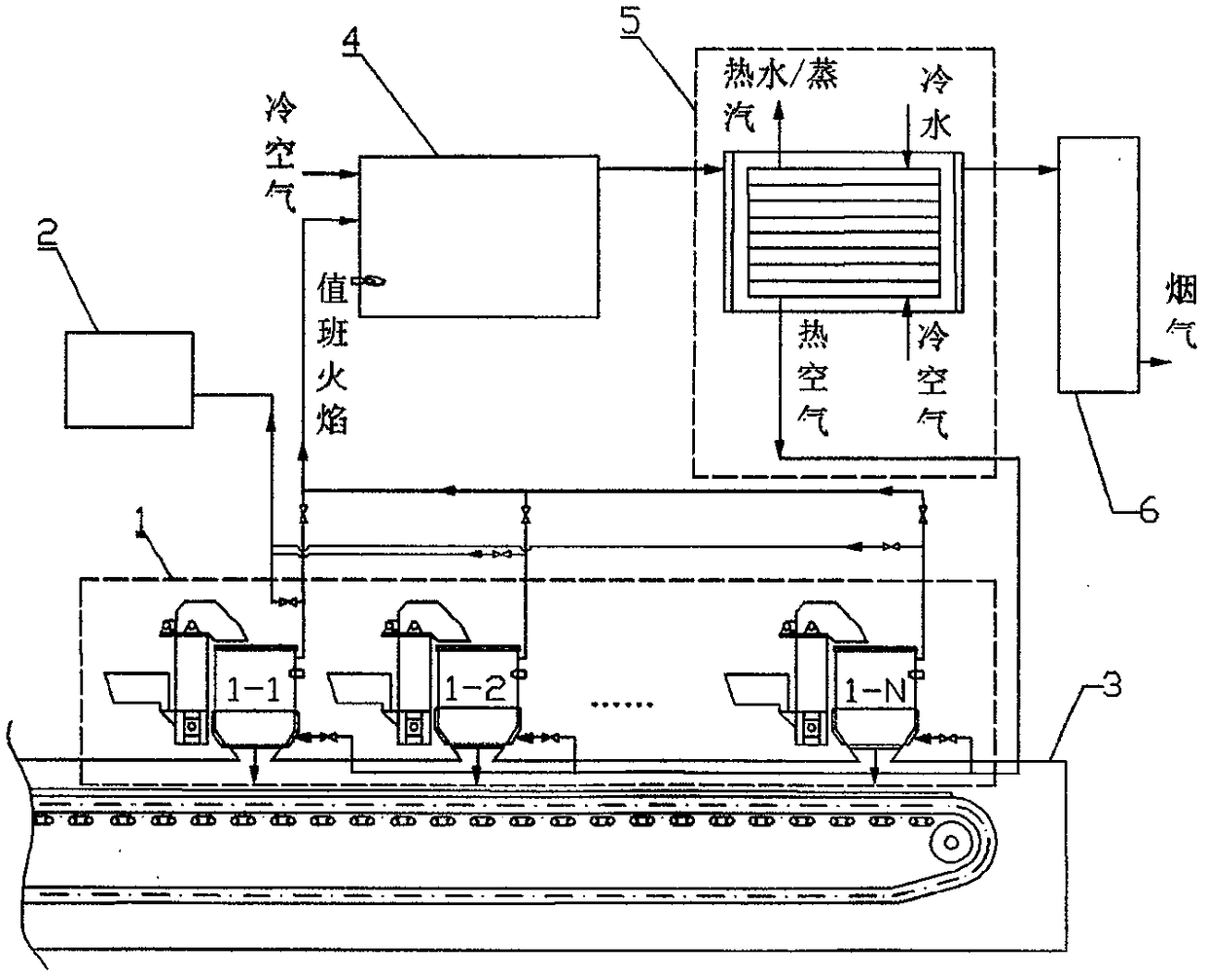

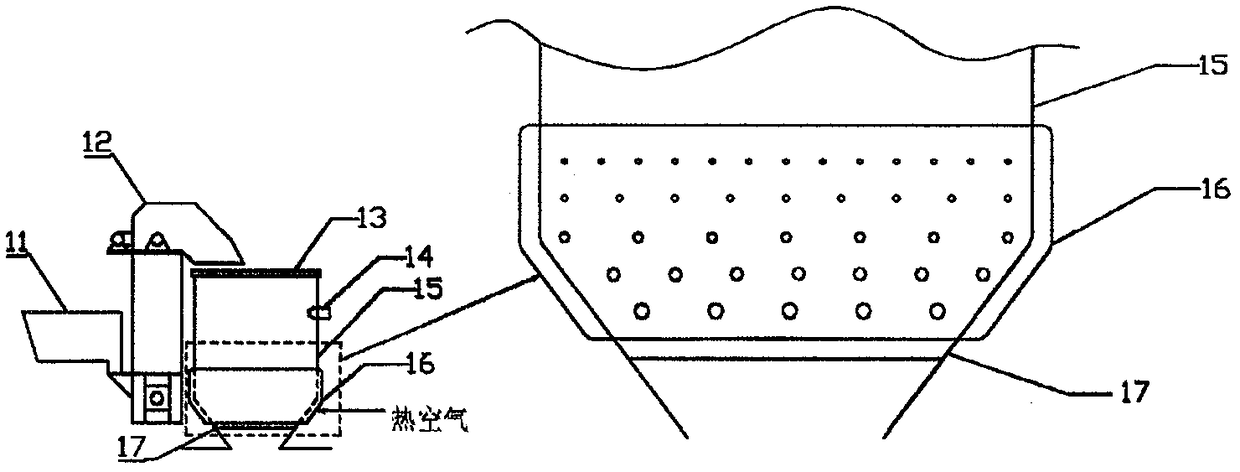

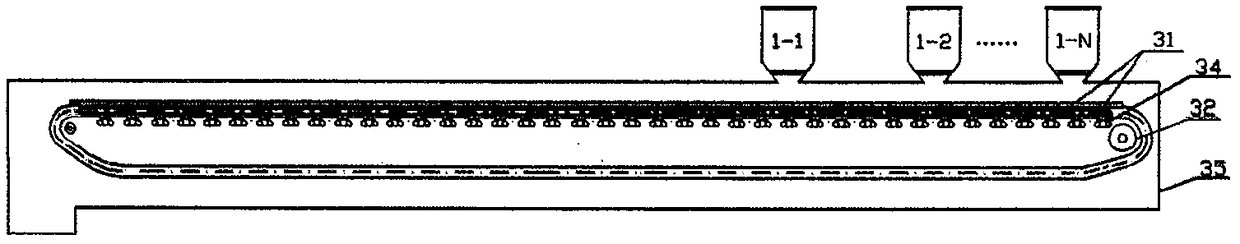

[0046] The garbage pyrolysis system 1 in this embodiment is composed of four parallel fixed-bed pyrolysis reactors, and the above-mentioned devices are used to carry out the harmless treatment of garbage pyrolysis. Garbage enters the pyrolysis reactor through the hopper 11 and the feeding system 12, and the primary feeding amount of each reactor is 3t (moisture content 35%). Among the four fixed-bed pyrolysis reactors, two are in the pyrolysis stage (in the early stage and late stage of pyrolysis respectively), one is in the drying stage, and the other is in the feeding and discharging stage. The hot air temperature at the inlet of the fixed bed pyrolysis reactor is 160°C, and the flow rate in the drying stage is 500Nm 3 / h, the flow rate in the pyrolysis stage is 200Nm 3 / h, no heating air is supplied during the feeding and discharging stages. After the waste is dried in the fixed bed pyrolysis reactor, it is ignited and pyrolyzed. After the pyrolysis is completed, the res...

Embodiment 2

[0048] The garbage pyrolysis system 1 in this embodiment is composed of four parallel fixed-bed pyrolysis reactors, and the above-mentioned devices are used to carry out the harmless treatment of garbage pyrolysis. Garbage enters the pyrolysis reactor through the hopper 11 and the feeding system 12, and the primary feeding amount of each reactor is 3t (moisture content 37%). Among the four fixed-bed pyrolysis reactors, two are in the pyrolysis stage (in the early stage and late stage of pyrolysis respectively), one is in the drying stage, and the other is in the feeding and discharging stages. The hot air temperature at the inlet of the fixed bed pyrolysis reactor is 170°C, and the flow rate in the drying stage is 500Nm 3 / h, the flow rate in the pyrolysis stage is 200Nm 3 / h, no heating air is supplied during the feeding and discharging stages. After the waste is dried in the fixed bed pyrolysis reactor, it is ignited and pyrolyzed. After the pyrolysis is completed, the re...

Embodiment 3

[0050] The garbage pyrolysis system 1 in this embodiment is composed of 8 parallel fixed-bed pyrolysis reactors, and the above-mentioned devices are used to carry out the harmless treatment of garbage pyrolysis. Garbage enters the pyrolysis reactor through the hopper 11 and the feeding system 12, and the primary feeding amount of each reactor is 3.2t (moisture content 35%). Among the 8 fixed-bed pyrolysis reactors, 4 are in the pyrolysis stage (2 are in the early stage of pyrolysis, and 2 are in the late stage of pyrolysis), 2 are in the drying stage, and the other 2 are in the feeding and discharging stages. The hot air temperature at the inlet of the fixed bed pyrolysis reactor is 160°C, and the flow rate in the drying stage is 500Nm 3 / h, the flow rate in the pyrolysis stage is 200Nm 3 / h, no heating air is supplied during the feeding and discharging stages. After the waste is dried in the fixed bed pyrolysis reactor, it is ignited and pyrolyzed. After the pyrolysis is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com