Device and method for applying a medium to a moving fibrous web on both sides

A fiber material and equipment technology, which is used in fiber material processing, devices for coating liquid on the surface, coatings, etc., to achieve the effect of less wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

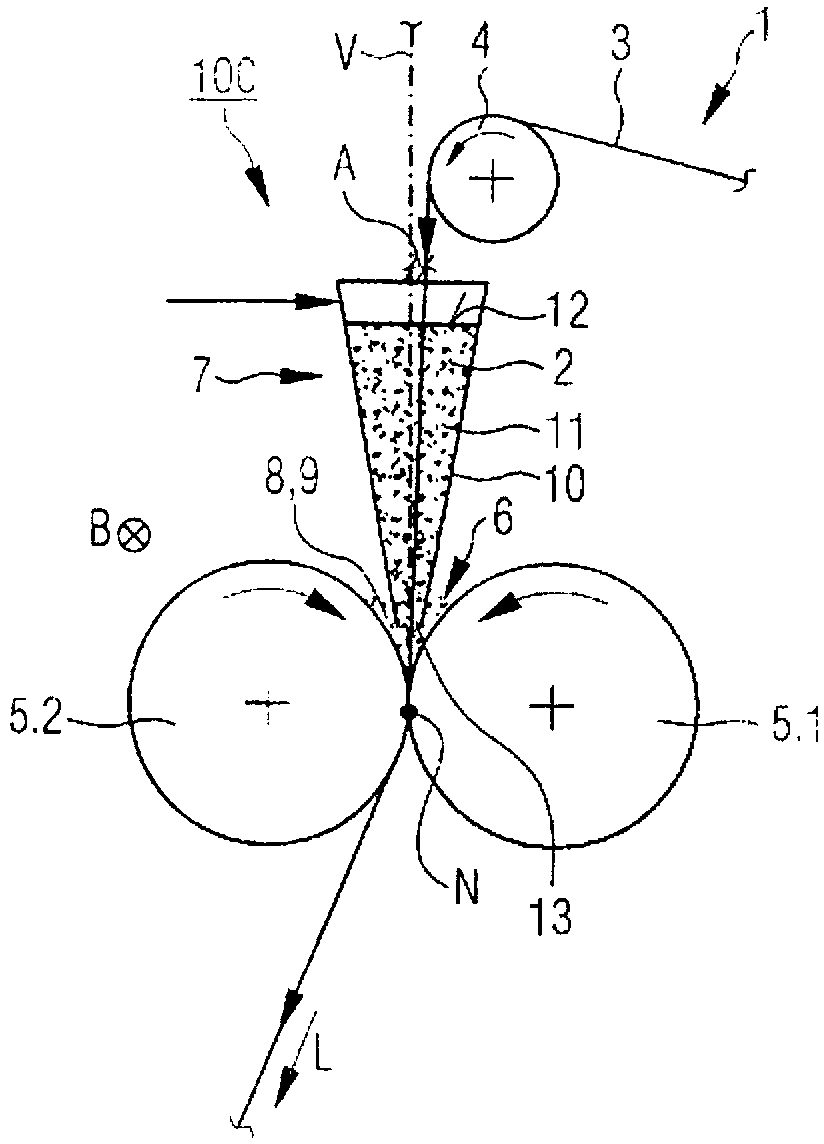

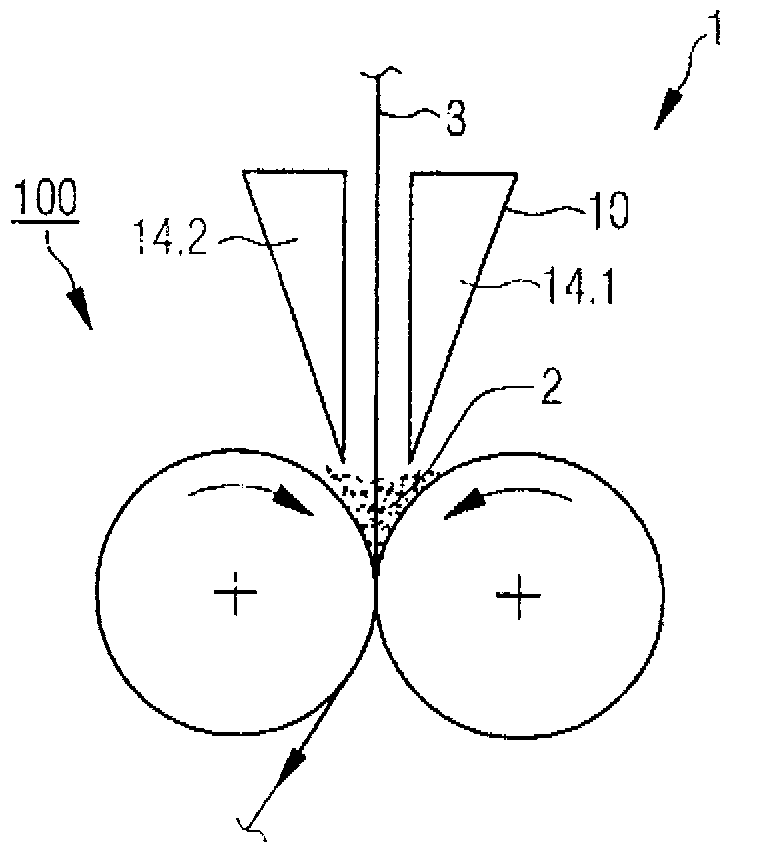

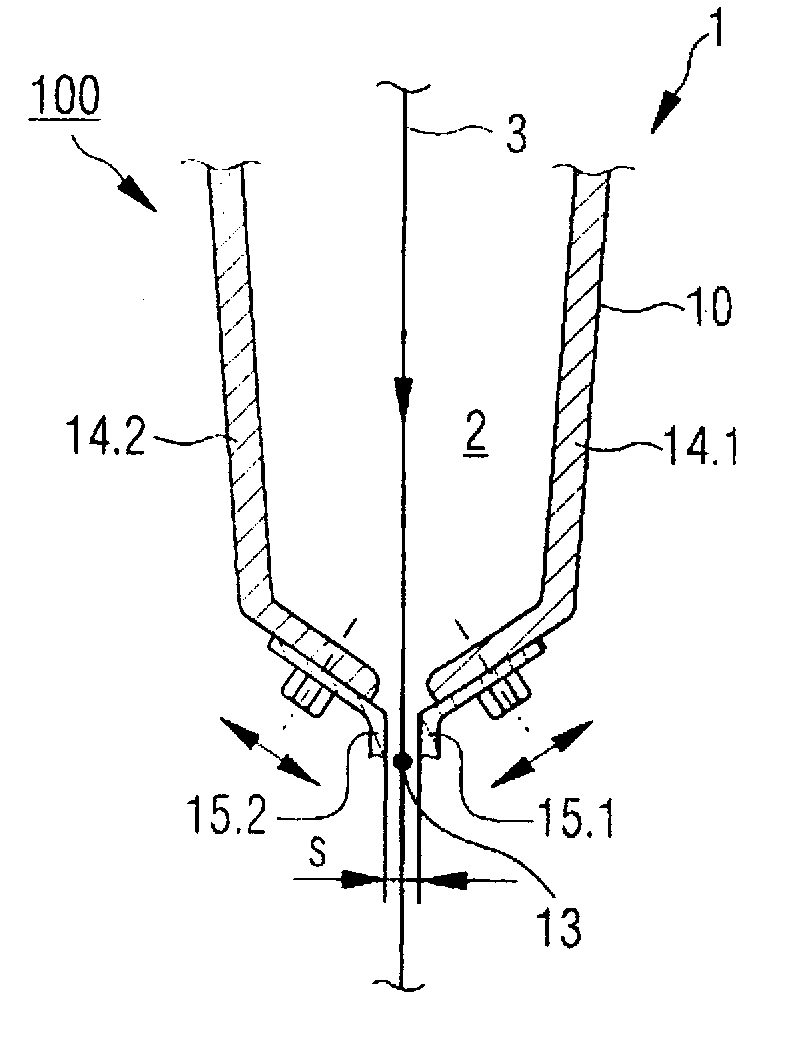

[0033] figure 1 A cross-section of a device 1 for applying a liquid or pasty medium 2 to both sides of a moving fibrous web 3 is shown. The fibrous web shown can be, for example, a banknote paper web 3 , wherein the fibrous web is usually glued with PVA as a liquid or pasty medium.

[0034] The deflection roll 4 and the two coating rolls, i.e. the first coating roll 5.1a and the second coating roll 5.2 are positioned relative to the moving fibrous web 3 such that the fibrous web 3 is guided by the two coating rolls 5.1 .5.2 Form the nip N. The two coating rollers 5.1.5.2 thus extend at least over the entire width B (arrow) of the moving fibrous web 3 and the nip N forms a roll introduction region 6 through which the moving fibrous web 3 is guided. Roller lead-in zone 6.

[0035]In addition, the device 1 has a conveying device 7 for feeding the liquid or pasty medium 2 into the roll introduction area 6, wherein, during operation of the device 1, a feed tank 8 through which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com