Continuously carbonizing device and method for preparing intermediate product carbonized material of carbon molecular sieve

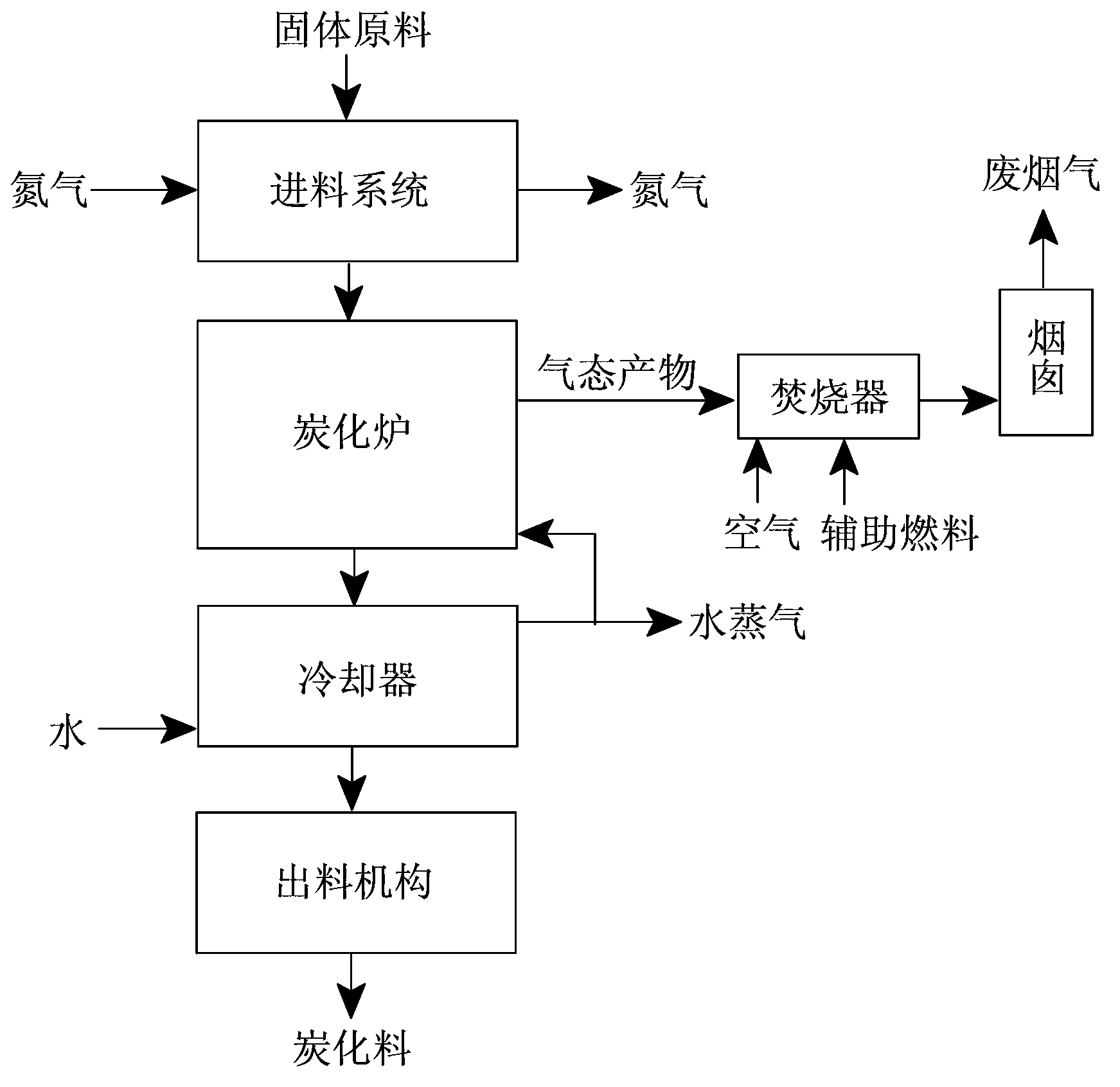

A carbon molecular sieve and carbonization device technology, applied in the field of continuous carbonization device, can solve the problem of unstable carbonized material quality and other problems, and achieve the effects of reducing the probability of secondary pyrolysis, good combustion performance, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

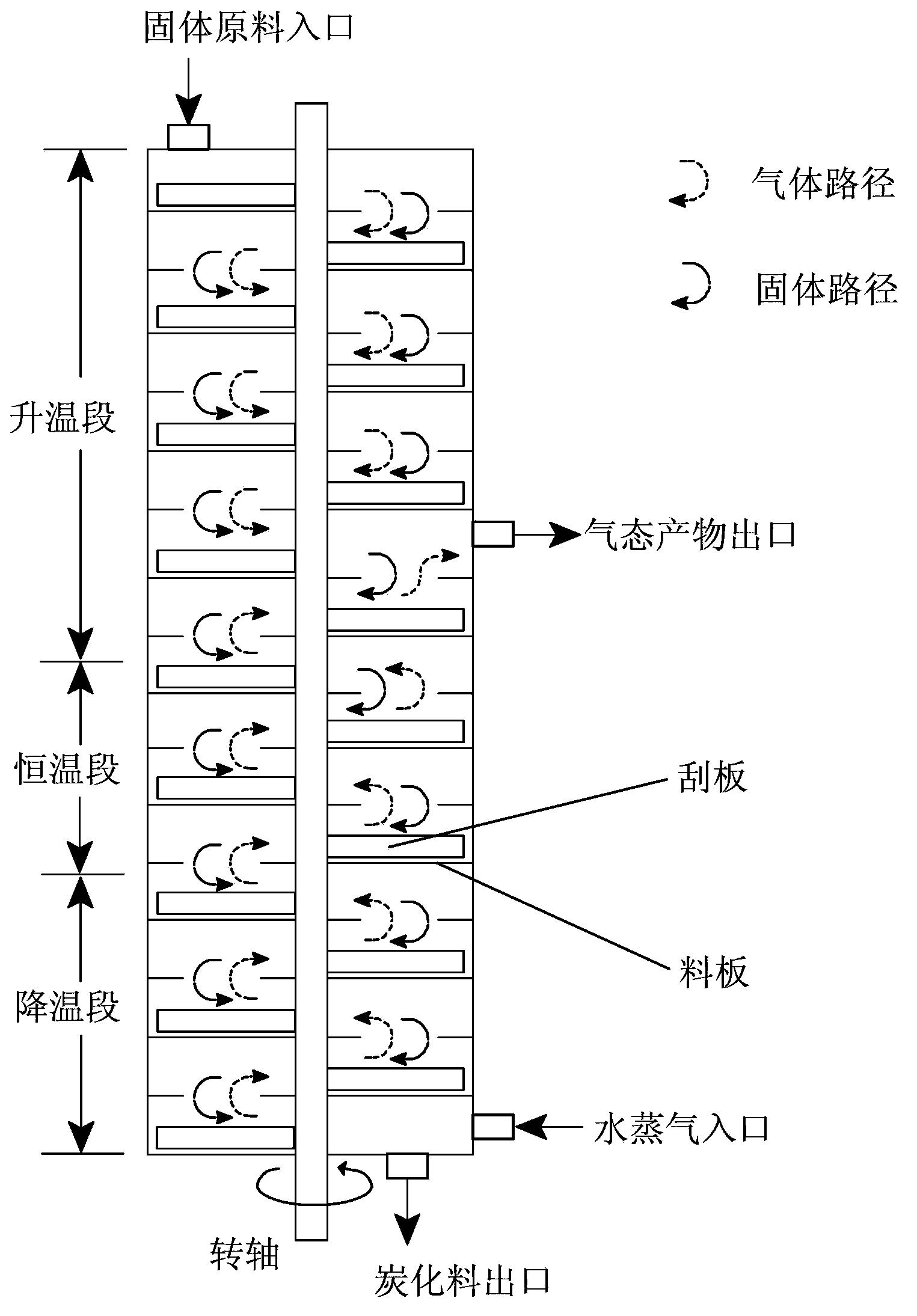

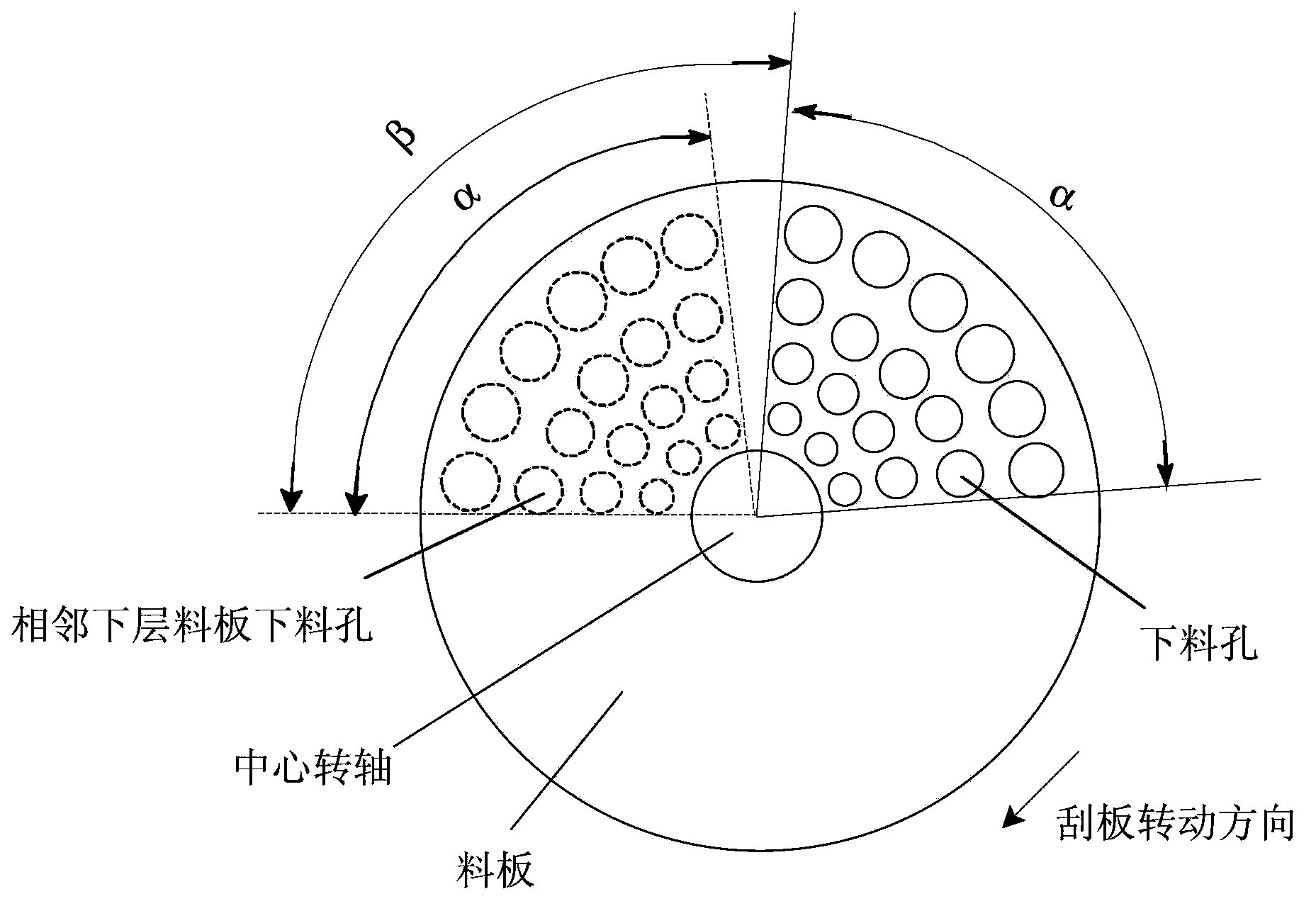

Embodiment 1

[0030] A small vertical carbonization furnace experimental device is adopted, and the operation process principle of the device is the same as Figure 1~Figure 3 . The main technical parameters of the device are as follows: the material of the vertical carbonization furnace is high temperature and corrosion resistant stainless steel, the effective height is 1206mm, the inner diameter is 120mm, the number of material plates is 45 layers, and the fan-shaped central angle α formed by the material plate blanking hole is 30 o , the total opening rate is 5%, and the position stagger angle β of the fan-shaped arrangement of the two adjacent material plates is 180 o ;The carbonization furnace is equipped with 5 sections of ring-shaped resistance furnaces that can be independently controlled. The resistance furnaces of each section have the same height and are evenly arranged between the top of the carbonization furnace and the 43rd layer of material plates. The bottom of the carboniza...

Embodiment 2

[0033] The main technical parameters of the device The central angle α of the sector of the material plate is 60 o , porosity 12%, other parameters with embodiment one. In the continuous carbonization experiment, the constant temperature time of the material was about 23 minutes, and other conditions were the same as in Example 1.

Embodiment 3

[0035]The main technical parameters of the device The central angle α of the sector of the material plate is 120 o , porosity 25%, other parameters with embodiment one. In the continuous carbonization experiment, the constant temperature time of the material was about 20 minutes, the feeding rate of the molding material was 0.6 kg / h, and other conditions were the same as in the first embodiment.

[0036] According to Embodiment 3, the continuous carbonization of 2 batches of 20 kg molding materials was respectively completed. The obtained carbonized material product is handed over to a carbon molecular sieve industrial manufacturer to further complete activation and carbon deposition to adjust pores to obtain a carbon molecular sieve product. Table 1 shows the test results of the physical properties of the carbon molecular sieve products provided by the manufacturer; Table 2 shows the test results of the pressure swing adsorption air separation of the carbon molecular sieve p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com