Microfluidic bubble removal device and preparation method thereof as well as microfluidic device

A bubble removal and microfluidic technology, applied in the direction of liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of difficult application of microgravity environment and low exhaust efficiency, so as to overcome the dependence on gravity and improve exhaust Efficiency, the effect of meeting exhaust requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

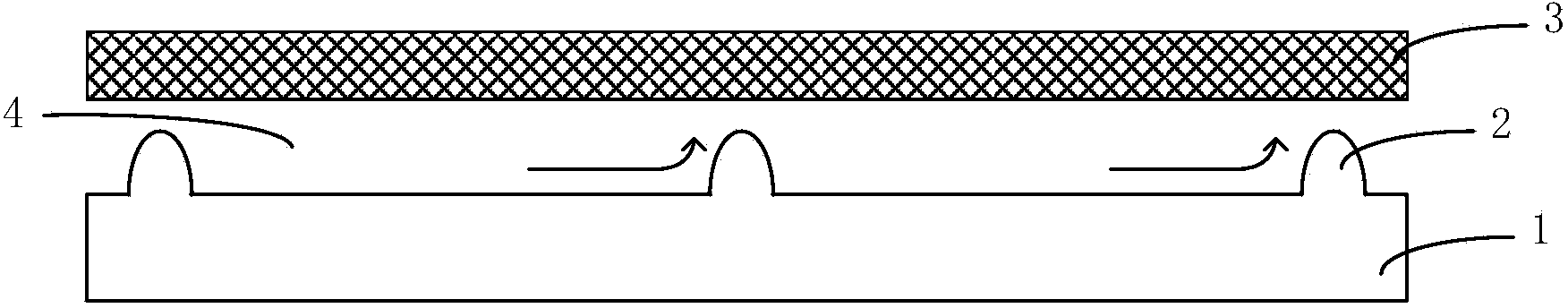

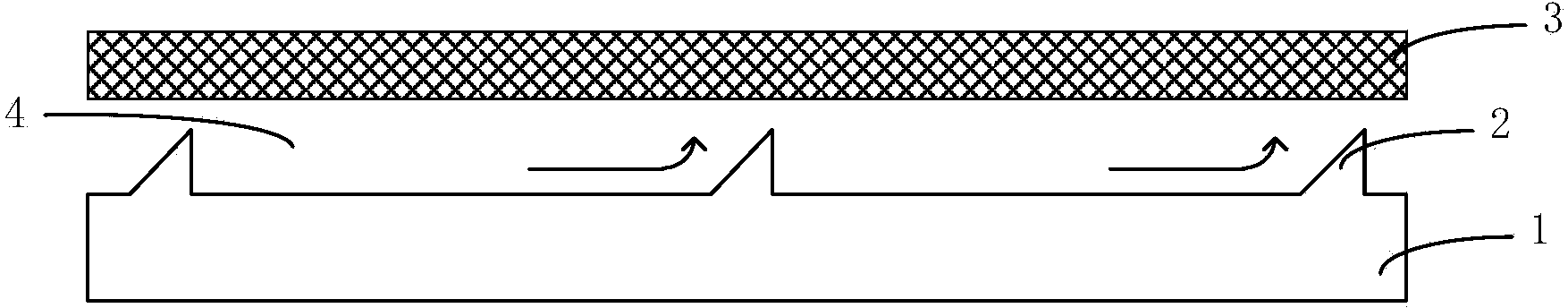

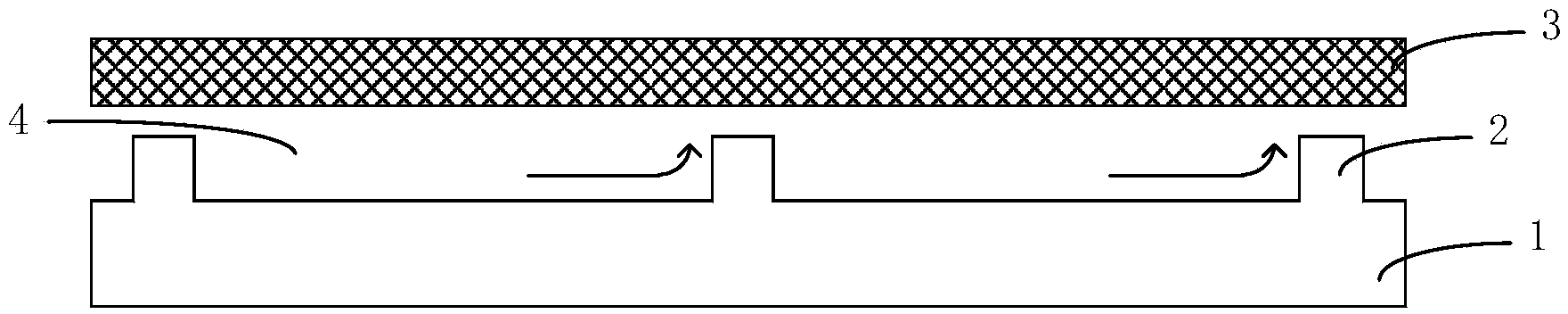

[0037] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the microfluidic bubble removal device of the present invention includes a channel bottom layer 1 and a hydrophobic porous layer 3, wherein the hydrophobic porous layer 3 is located on the channel bottom layer 1, and a channel bottom layer 1 and the hydrophobic porous layer 3 are formed. The microfluidic channel 4, the channel bottom layer 1 is located on one side of the microfluidic channel 4 and has at least one boss bar 2, the boss bar 2 is not in contact with the hydrophobic porous layer 3, the microfluid flows in the microfluidic channel 4, and the raised platform Bar 2 is disturbed due to the obstruction of boss bar 2 (such as figure 1 , figure 2 , image 3 shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com