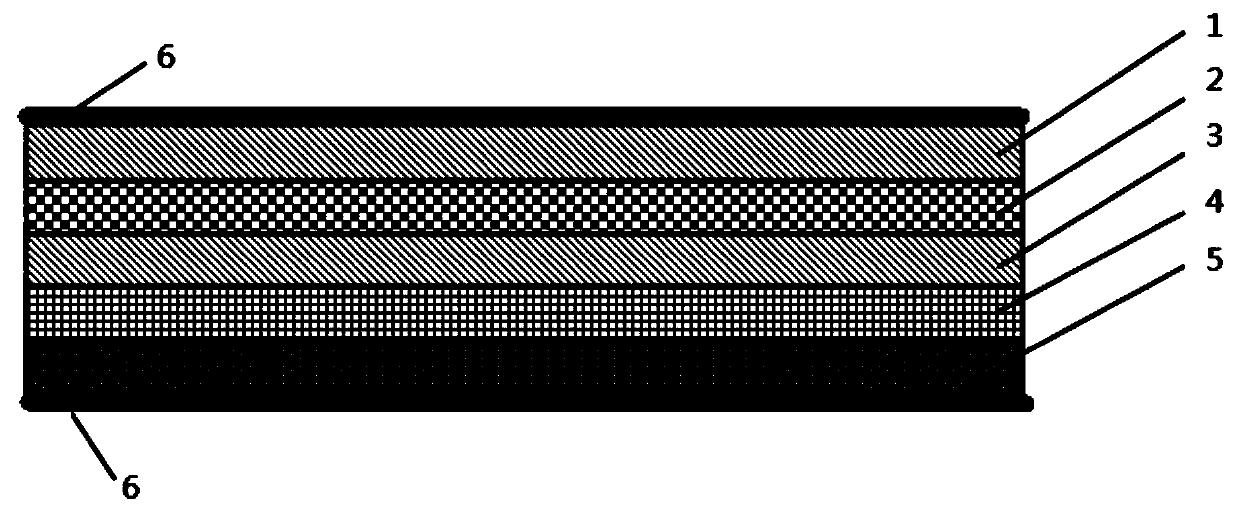

Multifunctional composite material armor plate and preparation method thereof

A composite material, bulletproof plate technology, applied in chemical instruments and methods, armor plate structure, synthetic resin layered products, etc., can solve problems such as inability to adapt, single protection function, etc., to improve exhaust efficiency and improve comfort. , Increase the effect of interface combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] T700 carbon fiber and Kevlar aramid fiber K29 are selected as the fiber raw materials for the rigid reinforcement layer respectively. The two fibers are prepared in the form of plain weave according to the mass ratio of 2:1 to prepare a two-dimensional fabric. The prepared fabric is impregnated with modified epoxy resin. The resin content Controlled at 35wt.%, made of prepreg for rigid reinforcement layer, the weight of prepreg is controlled at 120g / m 2 .

[0030] The ultra-high molecular weight polyethylene fiber with a strength of 40g / d was selected as the raw material, T700 carbon fiber was selected as the auxiliary raw material, and the mixed fiber unidirectional fabric was prepared according to the fiber mass ratio of 2:1. The impregnated adhesive resin used for the two fibers was modified Polyurethane, the glue content is controlled at 30wt.%. The prepared unidirectional fabric is laminated in the direction of ±90° to prepare the raw material for the intermediate ...

Embodiment 2

[0035] T700 carbon fiber is selected as the fiber raw material for the rigid reinforcement layer, and two-dimensional fabrics are prepared in the form of satin weaving. The prepared fabric is impregnated with modified epoxy resin, and the resin content is controlled at 40wt.%. The prepreg for the rigid reinforcement layer is made. The weight of prepreg is controlled at 100g / m 2 .

[0036] The ultra-high molecular weight polyethylene fiber with a strength of 40g / d was selected as the raw material, T300 carbon fiber was selected as the auxiliary raw material, and the mixed fiber unidirectional fabric was prepared according to the fiber mass ratio of 3:1. The impregnated adhesive resin used for the two fibers was modified Polyurethane, the glue content is controlled at 25wt.%. The prepared unidirectional fabric is laminated according to the direction of ±90° to prepare the intermediate bulletproof layer prepreg raw material, and the weight of the prepreg is controlled at 75g / m 2...

Embodiment 3

[0041] T300 carbon fiber is selected as the fiber raw material for the rigid reinforcement layer, and two-dimensional fabrics are prepared in the form of twill weave. The prepared fabric is impregnated with modified epoxy resin, and the resin content is controlled at 35wt.%, to make a prepreg for the rigid reinforcement layer. The weight of the dipping material is controlled at 100g / m 2 .

[0042] The ultra-high molecular weight polyethylene fiber with a strength of 35g / d was selected as the raw material, T700 carbon fiber was selected as the auxiliary raw material, and the mixed fiber unidirectional fabric was prepared according to the fiber mass ratio of 4:1. The impregnated adhesive resin used for the two fibers was modified Polyurethane, the glue content is controlled at 30wt.%. The prepared unidirectional fabric is laminated in the direction of ±90° to prepare the raw material for the intermediate bulletproof layer prepreg, and the weight of the prepreg is controlled at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com