Filling method for reducing discharge of methane using wind force intensified ventilation

A methane and wind technology, applied in the field of quasi-aerobic landfill process, can solve the problems of increasing power consumption and management costs, and achieve the effects of speeding up the stabilization process, saving energy and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

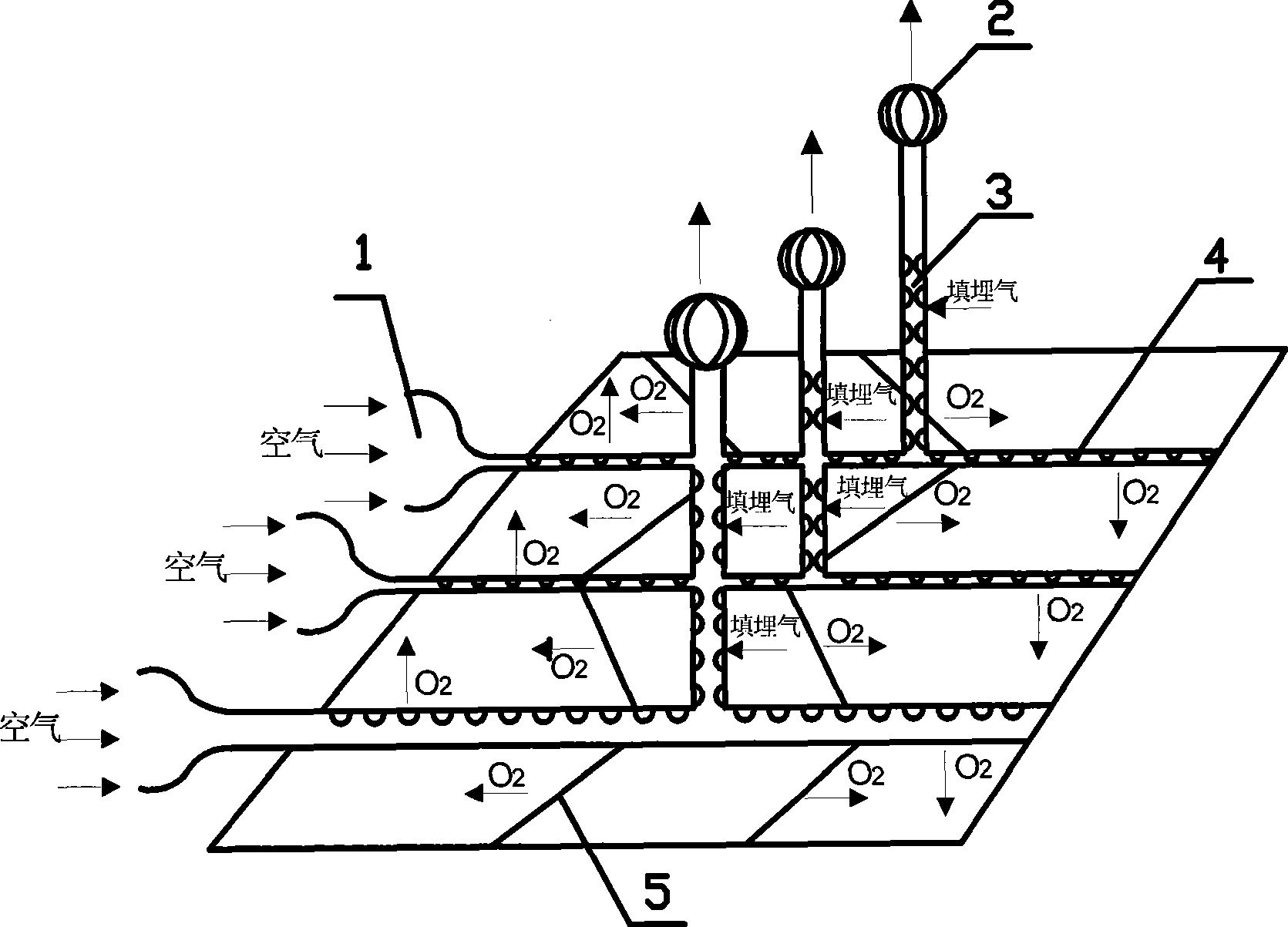

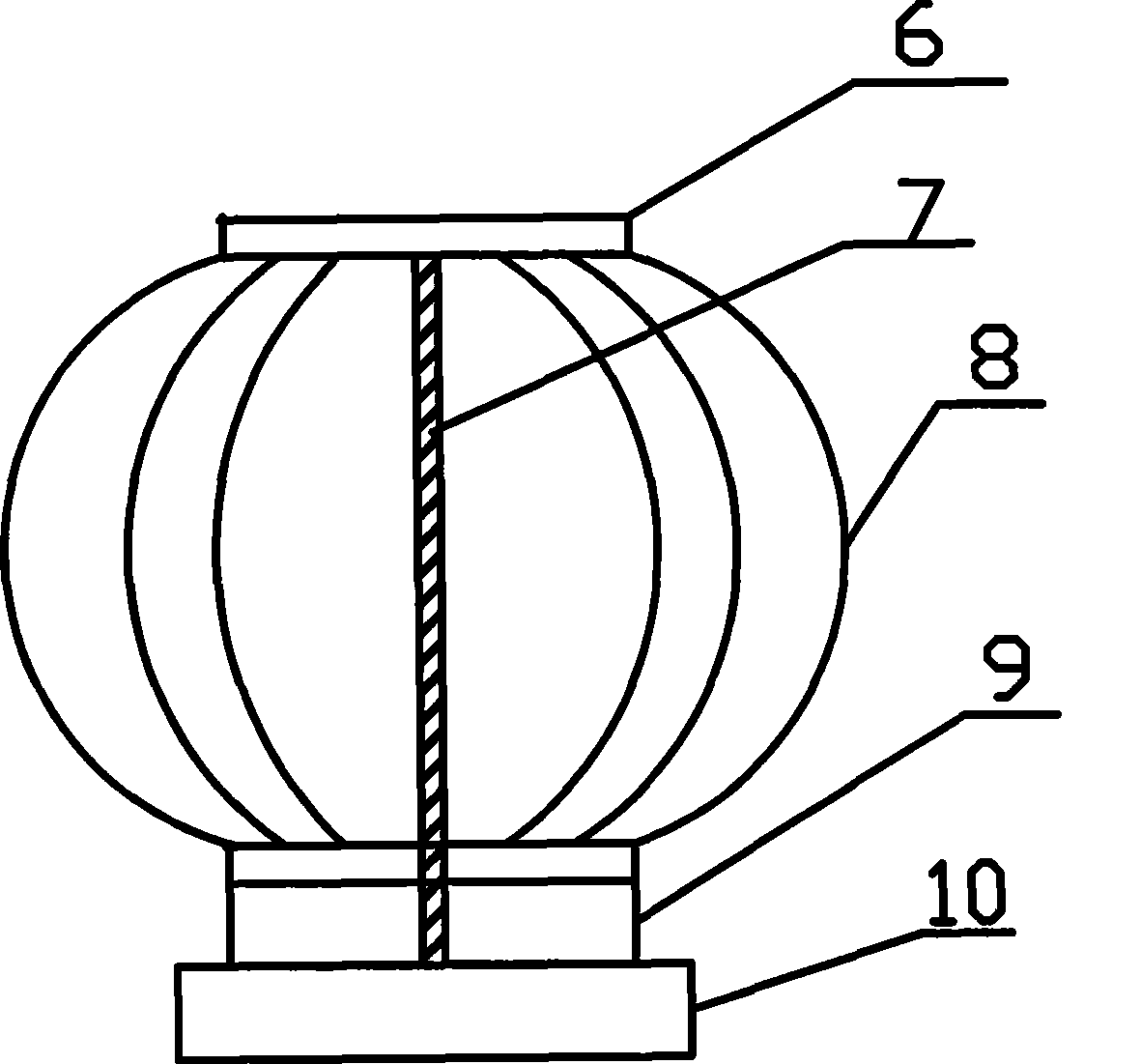

[0022] Please refer to the attached figure 1 , 2, 3, 4, 5, where figure 1 A structural schematic diagram of the implementation of the present invention is given.

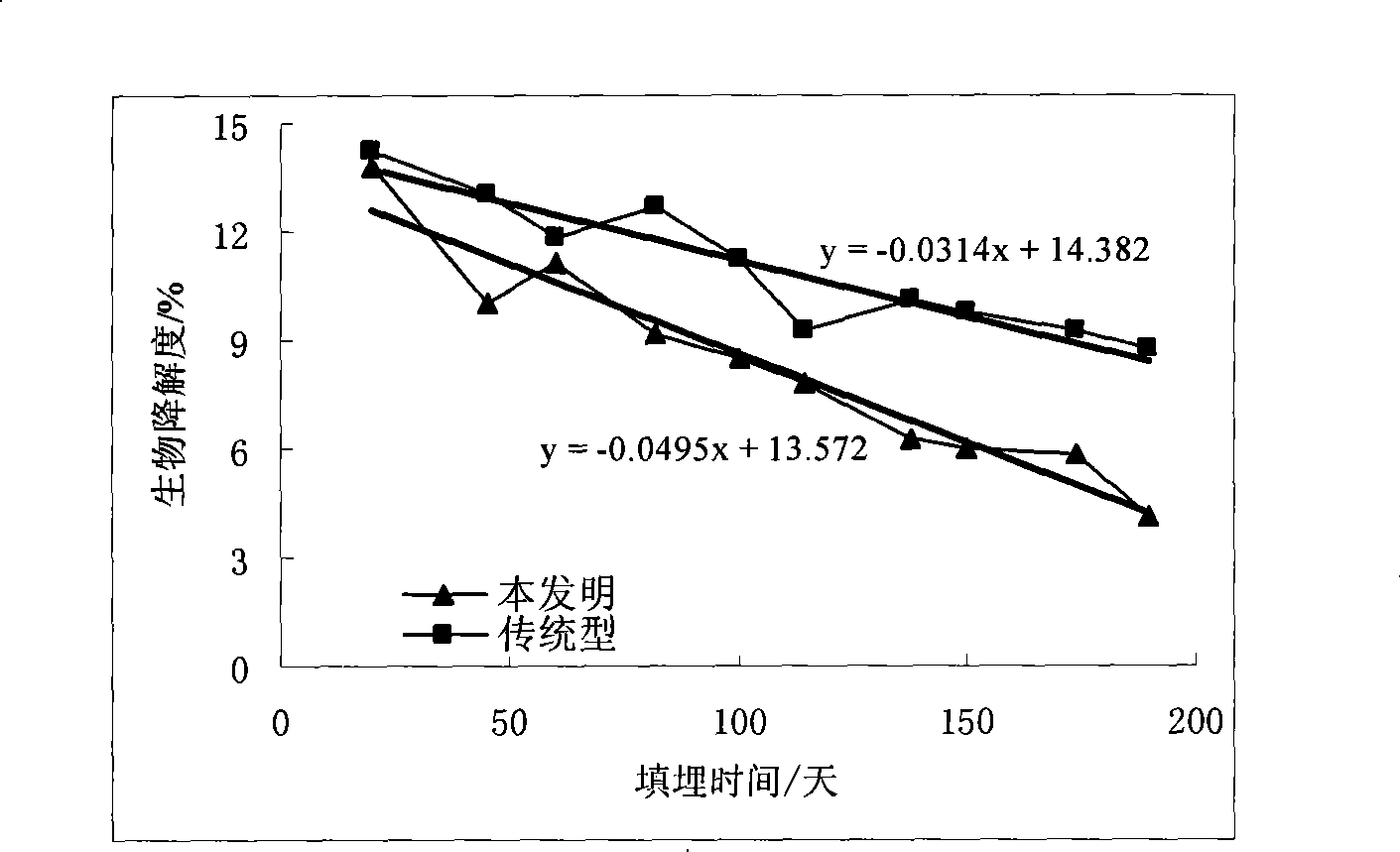

[0023] Firstly, two quasi-aerobic landfill simulation devices with the same internal structure and the same scale as 2m×1m×1.5m are established. One is a traditional quasi-aerobic landfill structure, and the other is a structurally improved landfill method according to the present invention. . The same structure is: the main leachate collection pipe 4 and the leachate collection branch pipe 5 are upper semicircular perforated pipes with a hole diameter of 12.5mm and a hole spacing of 50mm. The leachate collection main pipe 4 and the leachate collection branch pipe 5 adopt branched distribution, that is, three leachate collection main pipes 4 with a diameter of 150 mm are used, and two diameters of 100 mm are evenly distributed on both sides of each leachate collection main pipe 4 The leachate collection branch pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com