Seven planet screw combination device and method for plastifing, exhausting and extruding

An extrusion device and screw technology, which is applied in the field of seven-screw planetary combined plasticizing and exhaust extrusion device, can solve the problems that the effect cannot be effectively maintained for a long time, the interface reorientation effect is weakened, and the residence time distribution is difficult, and achieves excellent dispersion. Distributed mixing effect, changing melting mechanism and process, exhausting efficiency and effect of improving thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

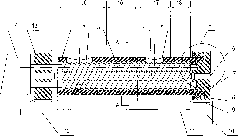

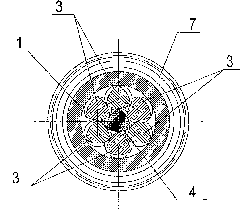

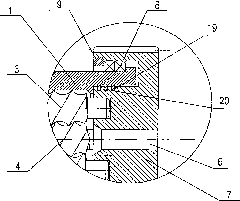

[0041] Figure 1 ~ Figure 3 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the seven-screw planetary combination plasticizing and venting extrusion device includes a screw mechanism, a barrel 1, a feed port 2, an exhaust port 5, a discharge port 6 and a power mechanism, and the power mechanisms are respectively arranged on the machine. The two ends of the cylinder 1 are connected with the screw mechanism; the screw mechanism is arranged inside the cylinder 1 and placed horizontally, and the inside of the cylinder 1 is a solid conveying section 15, a melting section 16, an exhaust section 17 and a mixing Extrusion section 18; the feed inlet 2 is located above the cylinder 1 of the solid delivery section 15, and the exhaust port 5 is located above the cylinder 1 of the exhaust section 17, and the feed inlet 2 and the exhaust outlet 5 are all connected to The barrel 1 is connected; the discharge port 6 is located at the end of the ...

Embodiment 2

[0058] Present embodiment except following feature other structures are with embodiment 1: as Figure 4 As shown, each planetary screw 3 is connected with a three-head kneading block 22 in the screw section of the melting section 16 , and is connected with a three-head kneading block 21 in the screw section of the exhaust section 17 .

Embodiment 3

[0060] Present embodiment except following feature other structures are with embodiment 1: as Figure 5 As shown, the power mechanism is a drive mechanism 24, one end of the central screw 4 and the six planetary screws 3 are connected to the drive mechanism 24 through an output shaft, and the other end is arranged at the other end of the barrel. At this time, during the extrusion operation, the revolution speed of each planetary screw 3 around the central axis of barrel 1 is zero, that is, each planetary screw 3 only rotates around its own axis under the drive of the driving mechanism 24 .

[0061] Such as Figure 6 As shown, the inner cavity of the barrel 1 is a cylindrical inner cavity, and its inner surface is provided with six cylindrical grooves 23 that cooperate with each planetary screw 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com