Small and light cryogenic high-pressure hydrogen storage device

A hydrogen storage device, light-weight technology, applied in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problems of heavy overall mass, light weight without using small machines, and limited hydrogen storage density. Achieve the effect of reducing weight and cost, realizing long-term standby, and improving maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The present invention will be further described in detail below in conjunction with specific embodiments and drawings.

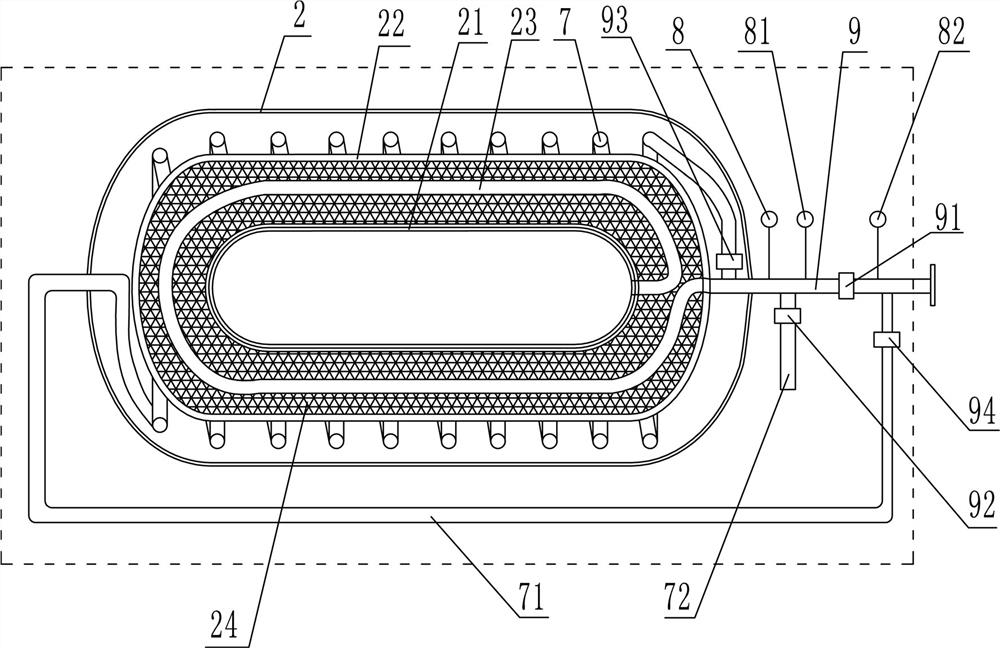

[0017]Such asfigure 1As shown, a small and lightweight cryogenic high-pressure hydrogen storage device includes: an inner bladder 21 and an outer cylinder 22. The inner bladder 21 is located in the outer cylinder 22. The inner bladder 21 is fully wound and wrapped by carbon fiber, and is wrapped in the carbon fiber layer. The outer side is also wrapped with a reflective insulation layer. A hydrogen pipe 23 is provided in the interlayer between the inner liner 21 and the outer cylinder 22. One end of the hydrogen pipe 23 is connected to the inner liner 21 from the head of the inner liner 21, and then The hydrogen pipe 23 is arranged in a circle around the inner liner 21 from the head of the inner liner 21 to the tail of the inner liner 21 and then to the head of the inner liner 21, and then the other end of the hydrogen pipe 23 passes through the head of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com