Energy-saving and environment-friendly high-temperature electric melting furnace

An energy-saving and environment-friendly electric melting furnace technology, which is applied in the direction of furnaces, furnace components, furnace control devices, etc., can solve the problems of large power consumption, energy consumption, and high production costs, so as to reduce heat emission, reduce safety hazards, and save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

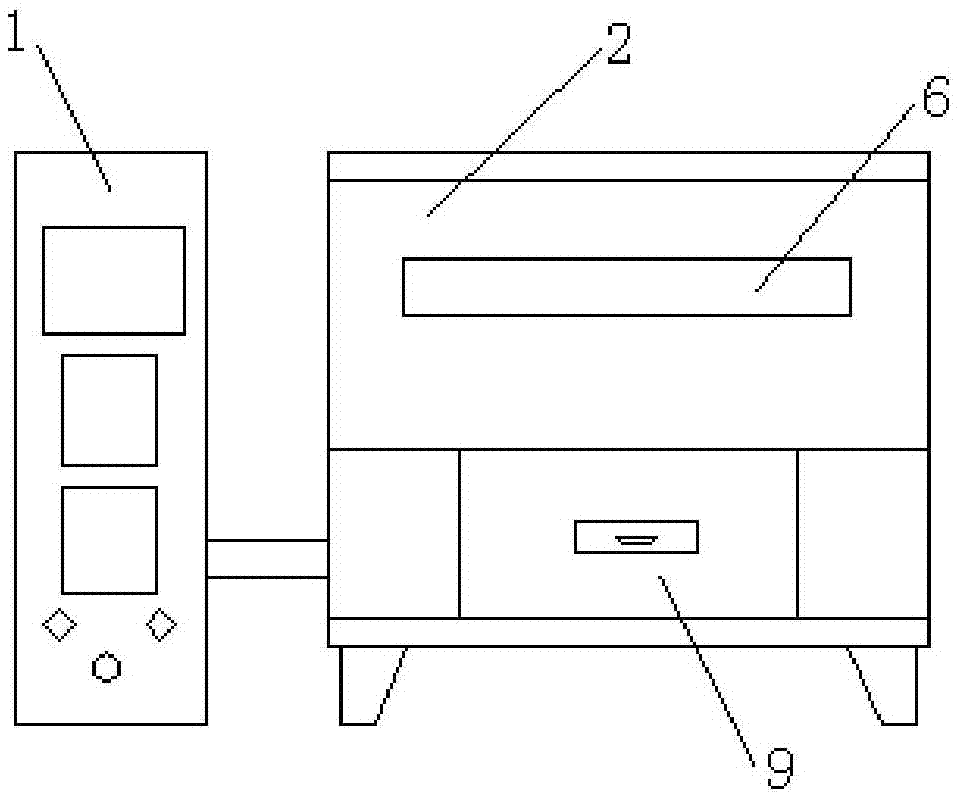

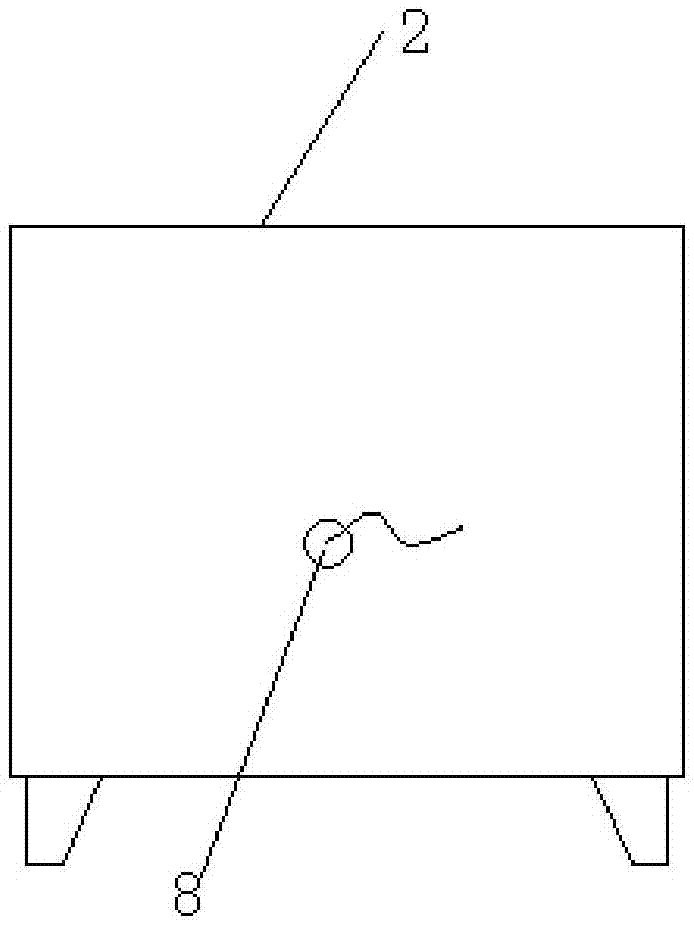

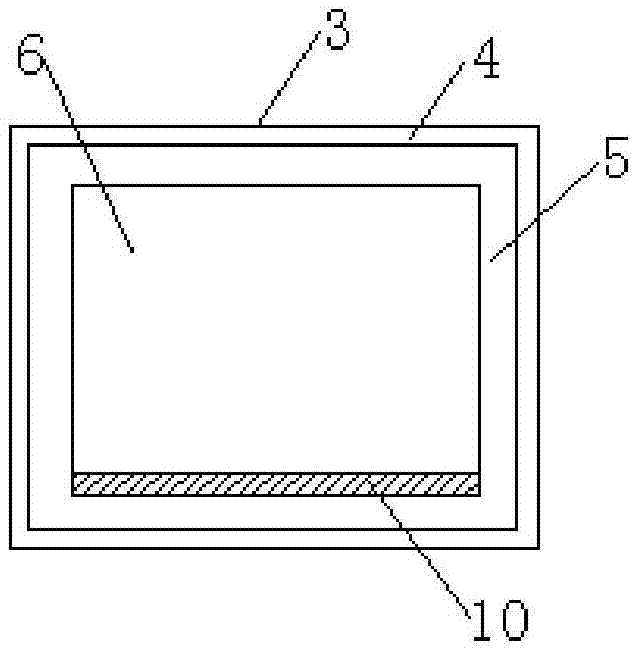

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown energy-saving and environment-friendly high-temperature electric melting furnace includes a control cabinet 1 and a furnace body 2; the control cabinet 1 is provided with a control panel; the furnace body 2 is composed of a furnace 3 and a furnace lining; the furnace 3 It consists of three layers of insulation, which are arranged successively from the outside to the inside: metal shell 4, ceramic fiberboard 5 and high-temperature-resistant alumina fiberboard 6; the surface of the high-temperature-resistant alumina fiberboard 6 is provided with multiple grooves, and the grooves are installed There are silicon-molybdenum rods 7 or silicon-carbon rods; a temperature-measuring element 8 is installed on the back of the furnace body 2, and the temperature-measuring part of the temperature-measuring element 8 extends into the furnace 3; the furnace 3 is a semi-open structure, A silicon carbide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com