Spinning multistage mixed flow burner

A burner and mixed-flow technology, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems such as the difficulty of turning on the low fire of the burner, and achieve the effect of full combustion, simple and reasonable structure, and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

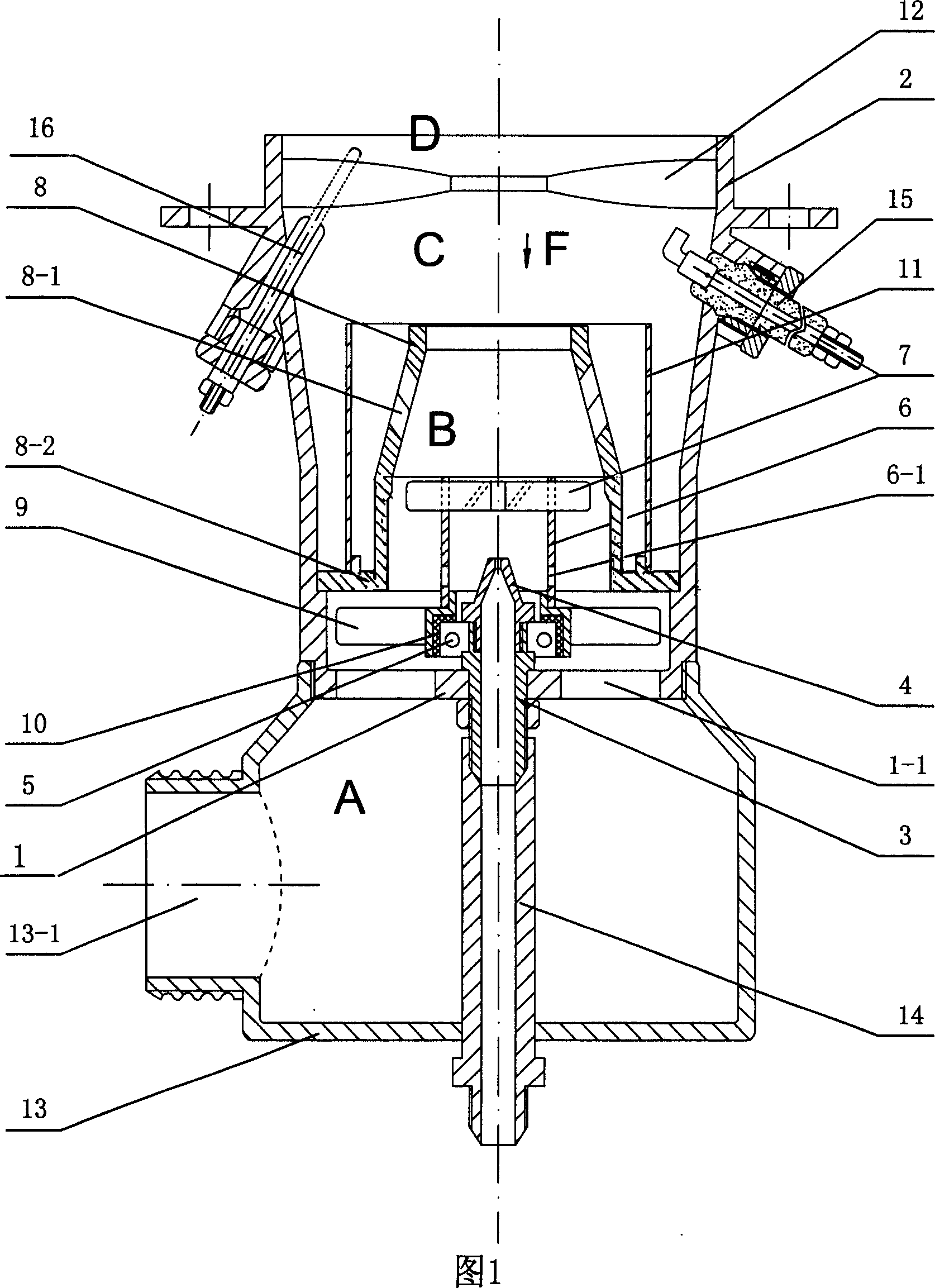

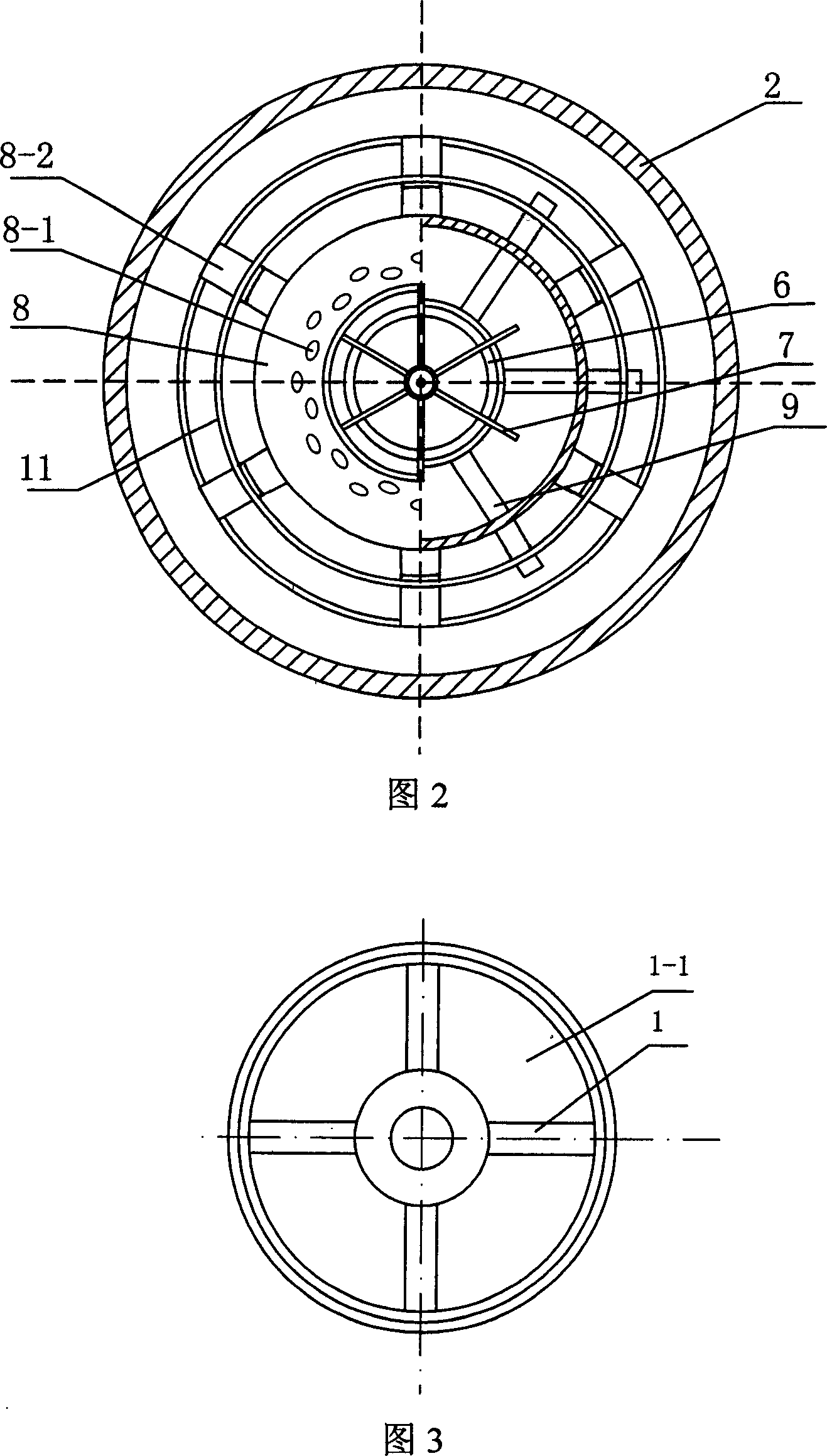

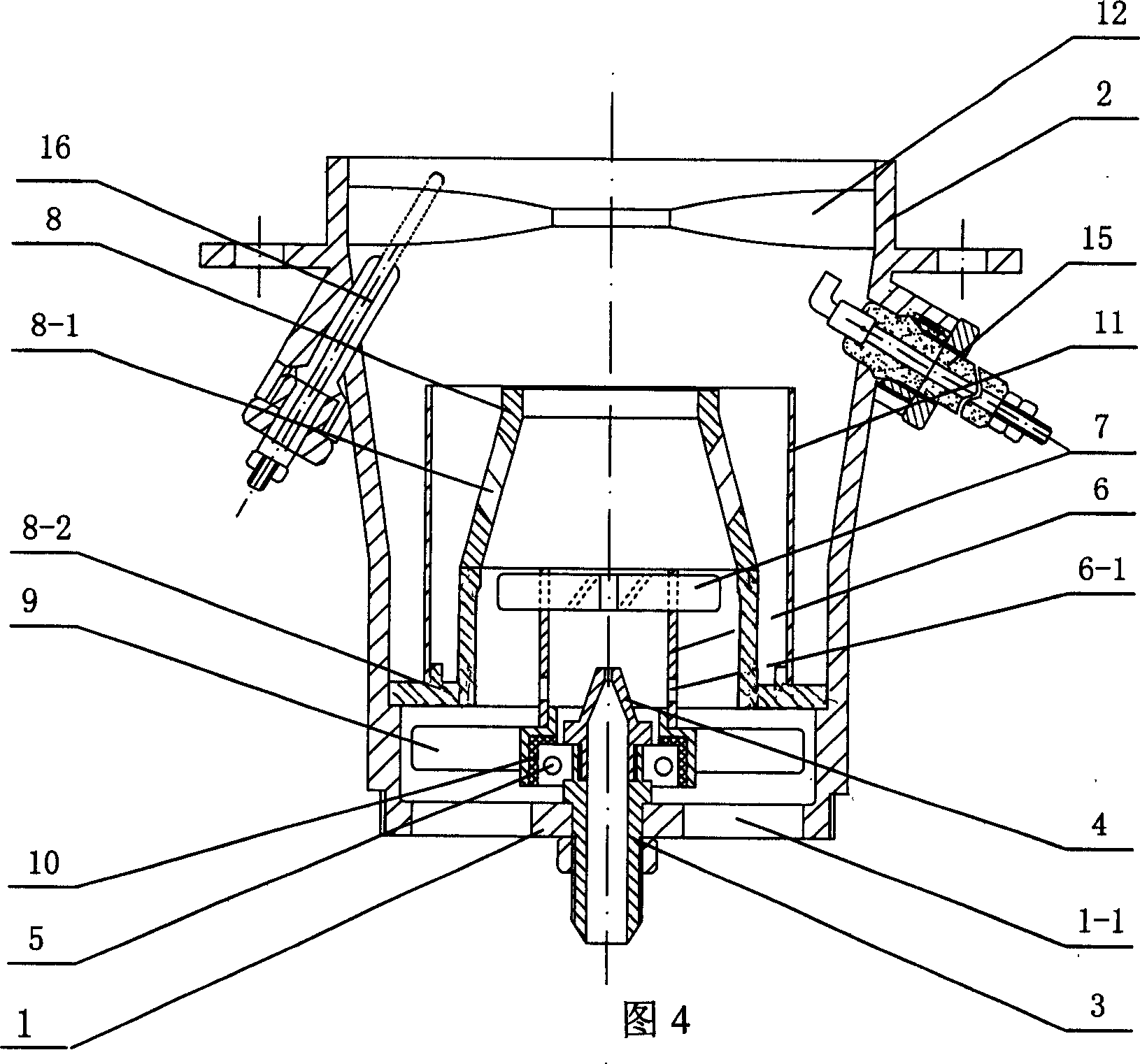

[0016] Example 1. See Figure 1 and Figure 2, this example is a two-stage mixed-flow burner with fan rotation, it has a shell 2 with a bottom plate 1, an igniter 15 and a flameout protector 16 are arranged inside the shell, and there are four fan-shaped air outlets 1 on the bottom plate -1 (see Figure 3). The central tube shaft 3 is fixed in the center of the bottom plate, and the center tube shaft body is provided with a bearing 5, and a heat-insulating bush 10 made of glass fiber material is arranged outside the bearing, and a rotor vane duct 6 is connected to the outer side of the heat-insulation bush. There are 6 upper wind blades 7 and lower wind blades 9 similar to electric fan blades respectively in the lower part; Inside the casing 2 there is a mixed-flow muffler cap 8 in the form of a few characters. The top of the muffler cap is open. Two rows of small holes 8-1 are arranged in a staggered arrangement on the wall of the cap. On the convex edge of the inner wall, the...

Embodiment 2

[0018] Example 2. As shown in Fig. 5, this example is a two-stage mixed-flow burner without fan rotation. Compared with Example 1, there is no air chamber 13 with a tuyere 13-1 at the shell-bottom portion, and no fuel connecting pipe 14 is provided. This example has a simple structure and a good combustion effect, and is especially suitable for night food stalls and families. The rest are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com