Motorcycle sound eliminator

A technology for mufflers and motorcycles, applied in mufflers, machines/engines, engine components, etc., can solve problems such as poor low-speed engine performance, increased rear wheel output, and sharp exhaust tail sounds, so as to improve medium and low-speed performance, improve The effect of exhaust noise and reduction of surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

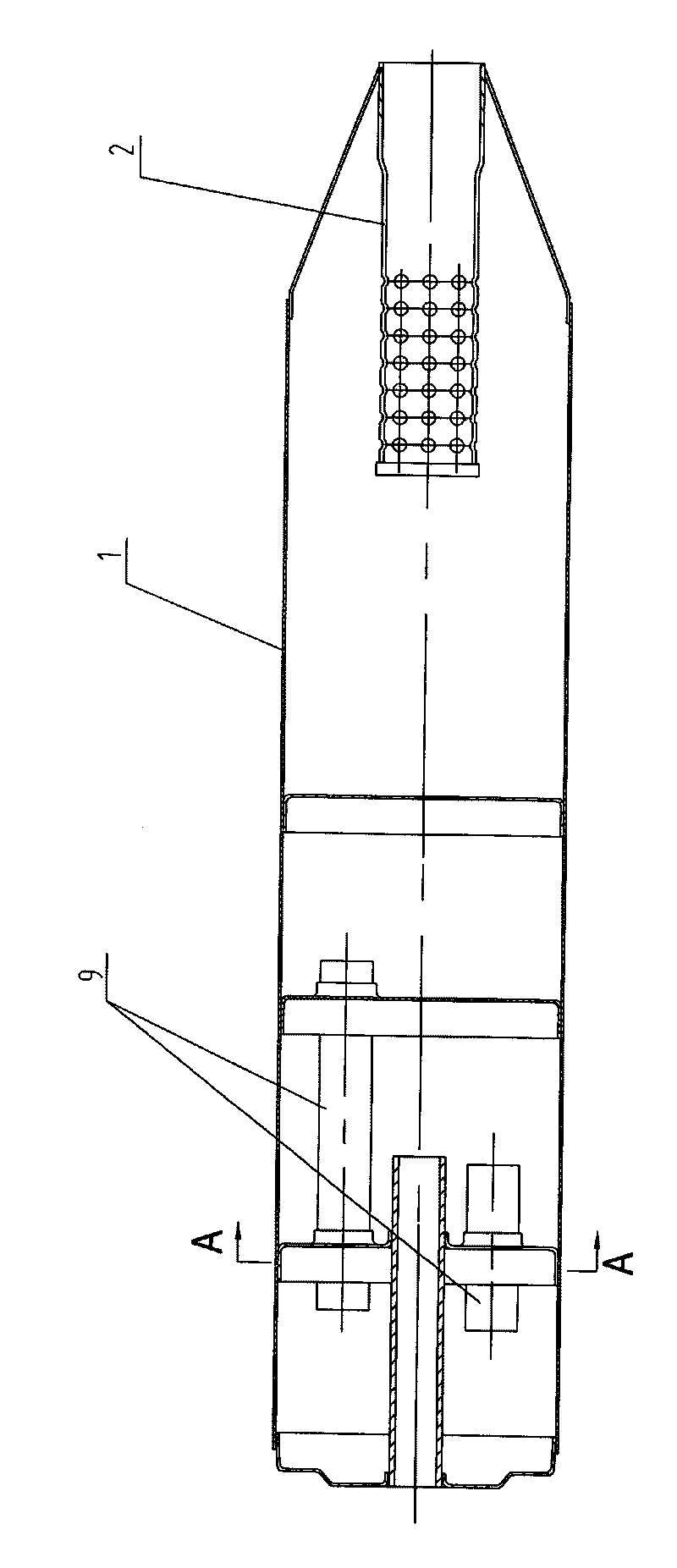

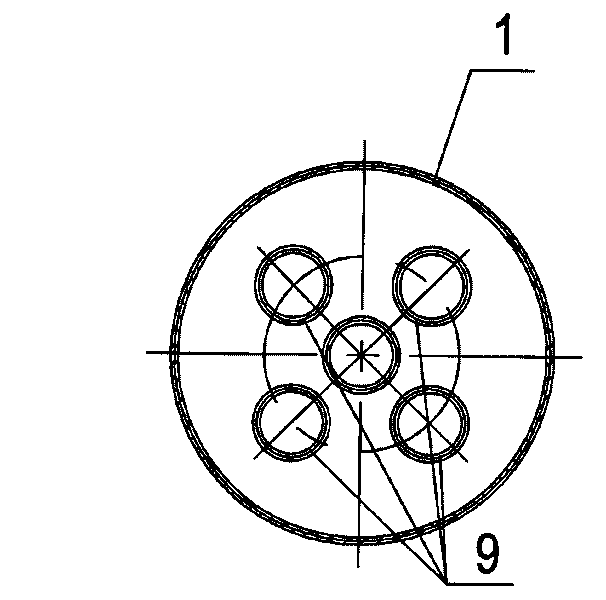

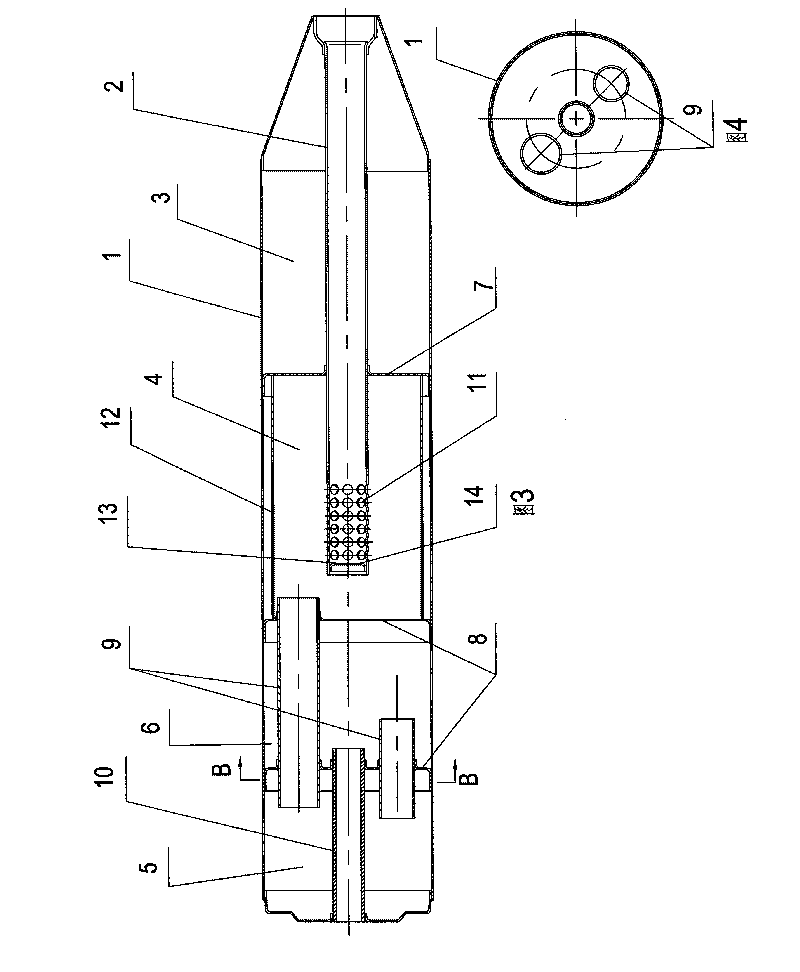

[0020] like image 3 As shown, the motorcycle muffler of the present invention is used with CG125 and CG150 engines, and has a muffler cylinder 1 and an inner connecting pipe 2. The inner cavity of the muffler cylinder 1 is divided into a first muffler chamber 3, a second muffler chamber Acoustic chamber 4, third anechoic chamber 5 and fourth anechoic chamber 6, wherein a perforated plate 7 is arranged between the first and second anechoic chambers 3 and 4, between the second and fourth anechoic chambers 4 and 6 Between the third and fourth anechoic chambers 5 and 6, a partition 8 is arranged, and between the second and third anechoic chambers 4 and 5 and between the third and fourth anechoic chambers 5 and 6 are guided The trachea 9 communicates, the fourth muffler chamber 6 communicates with the exhaust tailpipe 10, and the rear end pipe wall of the inner connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com