Gas generating agent composition having reduced solid discharge amount of inflator

A technology of a gas generating agent and composition, which is applied in the field of gas generating agent composition for inflators for inflating airbags, can solve problems such as increase in unit price, increase in volume and weight of inflators, highly toxic hydrazic acid, etc., and achieve protection Effects on drivers and passengers, reducing the risk of damage to airbags by high-temperature particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

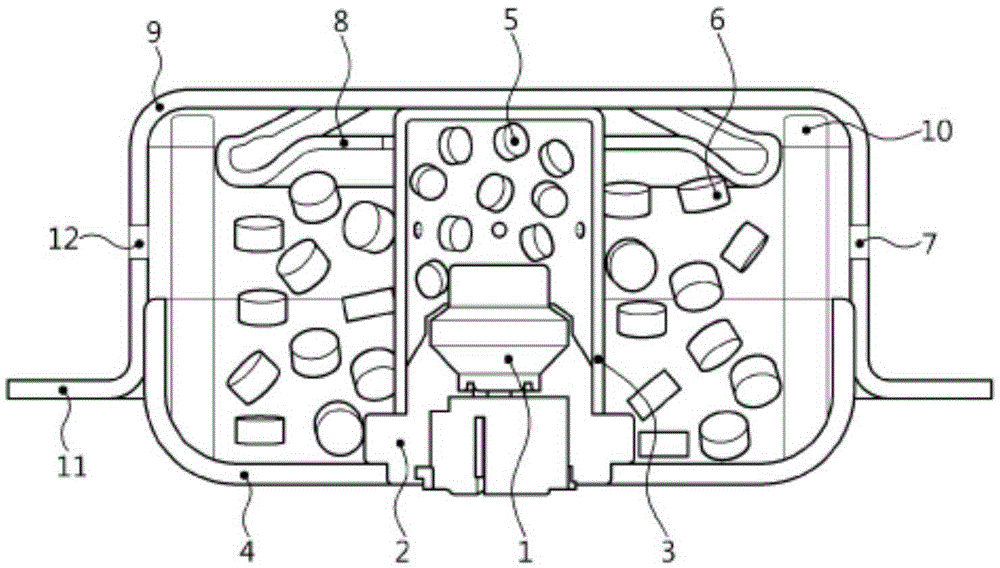

Image

Examples

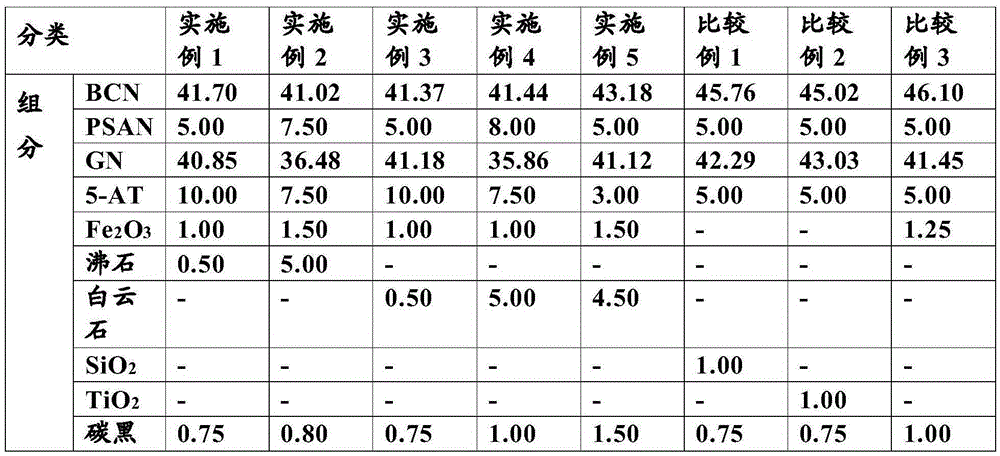

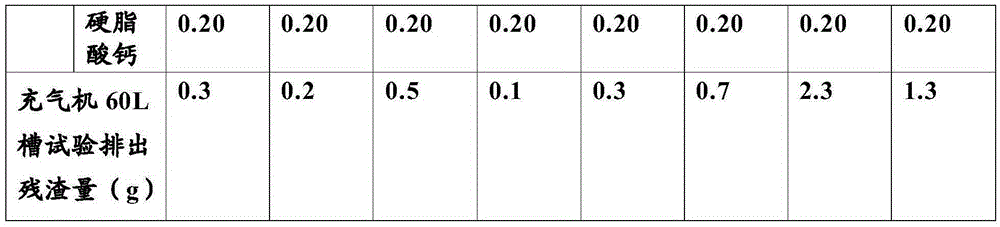

Embodiment 1

[0052] 40.85% by weight of mixed guanidine nitrate, 41.70% by weight of basic copper nitrate (BCN, BasicCopperNitrate), 10% by weight of 5-aminotetrazole (5-Aminotetrazole), 5% by weight of phase stabilized ammonium nitrate (PSAN, Phasestabilizedammoniumnitrate), Zeolite (Zeolite) 0.5% by weight, iron oxide (Ferricoxide: Fe 2 o 3) 1% by weight, carbon black 0.75% by weight and calcium stearate (CalciumStearate) 0.2% by weight and dried at 70°C for 4 hours. The average particle diameter of the gas generating agent mixture is 10-15 μm. The dried gas generant mixture was compression-molded into a gas generant tablet (Tablet) with a diameter of 6 mm and a height of 2.4 mm with a compression molding machine, and the gas generant tablet was filled in an inflator for a 60 L tank test, and the results showed that The amount of residue discharged was 0.3 g. The average particle size of zeolite (Zeolite) is 0.5-5 μm, and the particle size of 15 μm or less is used for other raw materi...

Embodiment 2

[0054] By adding 36.48% by weight of guanidine nitrate, 41.02% by weight of basic copper nitrate (BCN, BasicCopperNitrate), 7.5% by weight of 5-aminotetrazole (5-Aminotetrazole), and 7.5% by weight of phase stabilized ammonium nitrate (PSAN, Phasestabilizedammoniumnitrate) , Zeolite (Zeolite) 5% by weight, iron oxide (Ferricoxide: Fe 2 o 3 ) 1.5% by weight, 0.8% by weight of carbon black, and 0.2% by weight of calcium stearate (CalciumStearate) 0.2% by weight to manufacture a gas generating agent in the same manner as in Example 1, and use the gas generating agent for an inflator to carry out a 60L tank test. It was shown that the amount of residue discharged was 0.2 g. The average particle size of zeolite (Zeolite) is 0.5-5 μm, and the particle size of 15 μm or less is used for other raw materials.

Embodiment 3

[0056] By mixing guanidine nitrate (Guanidinenitrate) 41.18% by weight, basic copper nitrate (BCN, BasicCopperNitrate) 41.37% by weight, 5-aminotetrazole (5-Aminotetrazole) 10% by weight, phase stabilized ammonium nitrate (PSAN, Phasestabilizedammoniumnitrate) 5% by weight , dolomite (Dolomite) 0.5% by weight, iron oxide (Ferricoxide: Fe 2 o 3 ) 1% by weight, 0.75% by weight of carbon black and 0.2% by weight of calcium stearate (CalciumStearate) and the same method as in Example 1 to manufacture a gas generating agent, and use the gas generating agent for an inflator to carry out a 60L tank test, The results showed that the amount of residue discharged was 0.5 g. The average particle size of dolomite is 0.5-5 μm, and the particle size of 15 μm or less is used for other raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com