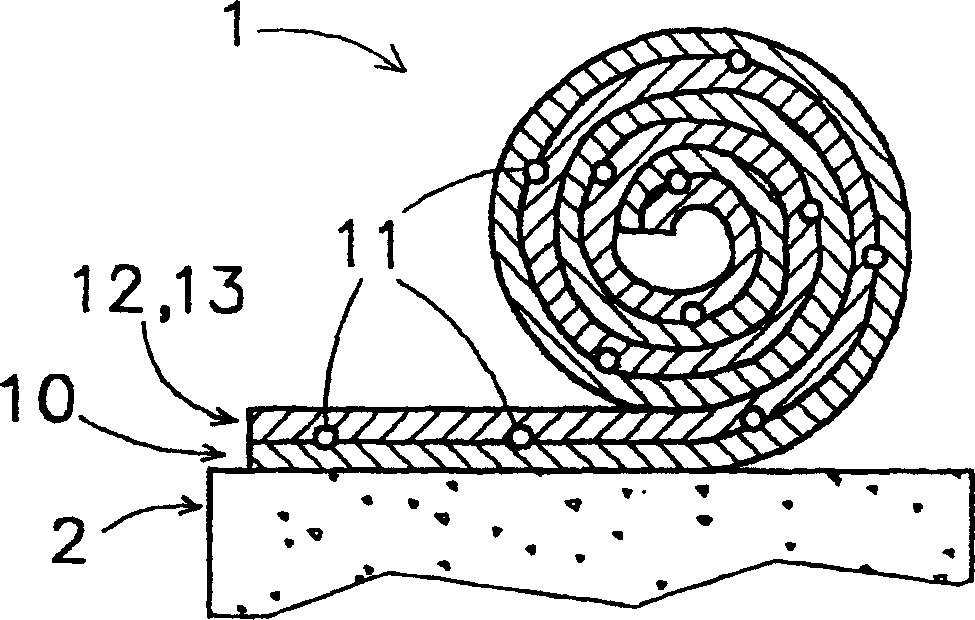

Roll-up heating for a floor, or wall

A heating device and floor technology, which is applied to household heating, electric heating devices, applications, etc., can solve problems such as being unsuitable for direct use and damaging heating elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

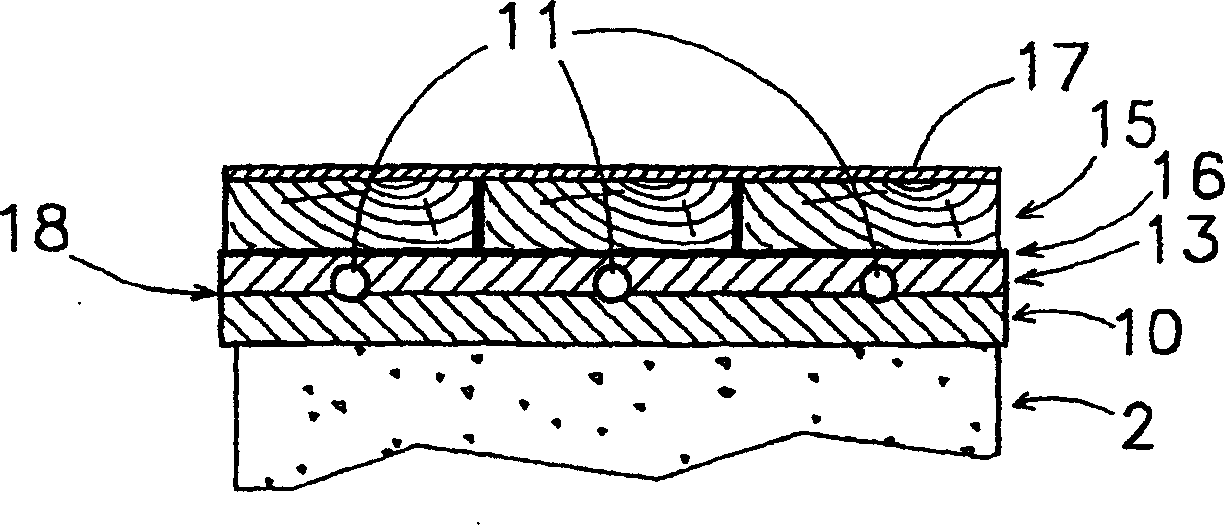

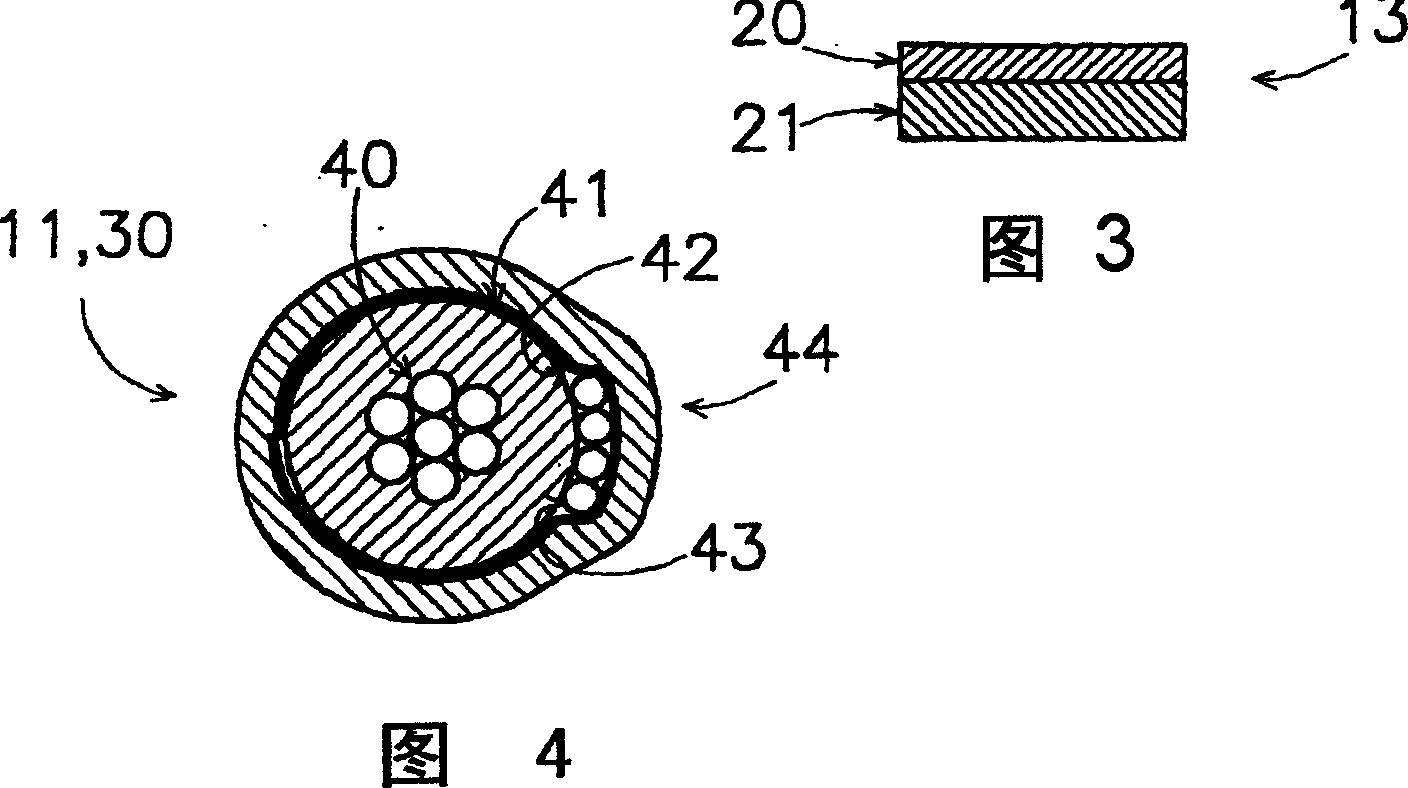

[0009] The preferred embodiments of the present invention are described in detail in the appended claims.

[0010] In one embodiment, the elastic modulus of the side of the force distribution layer facing the heat insulating layer is smaller than the other side thereof, specifically, the elastic modulus is at most 67% of the other side. Specifically, the force distribution layer includes a first layer and a second layer. The second layer faces the heat insulating layer. The elastic modulus of the first secondary layer is greater than that of the second elastic secondary layer. Due to the difference in elastic modulus, when a force is applied to a point on the force distribution layer, a higher pressure will be generated on the side farther from the heat insulating layer (specifically, on the first layer). The pressure is substantially in the plane of the force distribution layer, so that the top surface of the force distribution layer sags over a larger surface area. In this way, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com