Multiple reaction cavity atom layer deposition device and method

An atomic layer deposition, multi-reaction technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve problems such as environmental hazards, prolonged operation time, waste of reaction sources, etc., and reach the dangerous level of environmental damage The effect of reduction, good response control, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

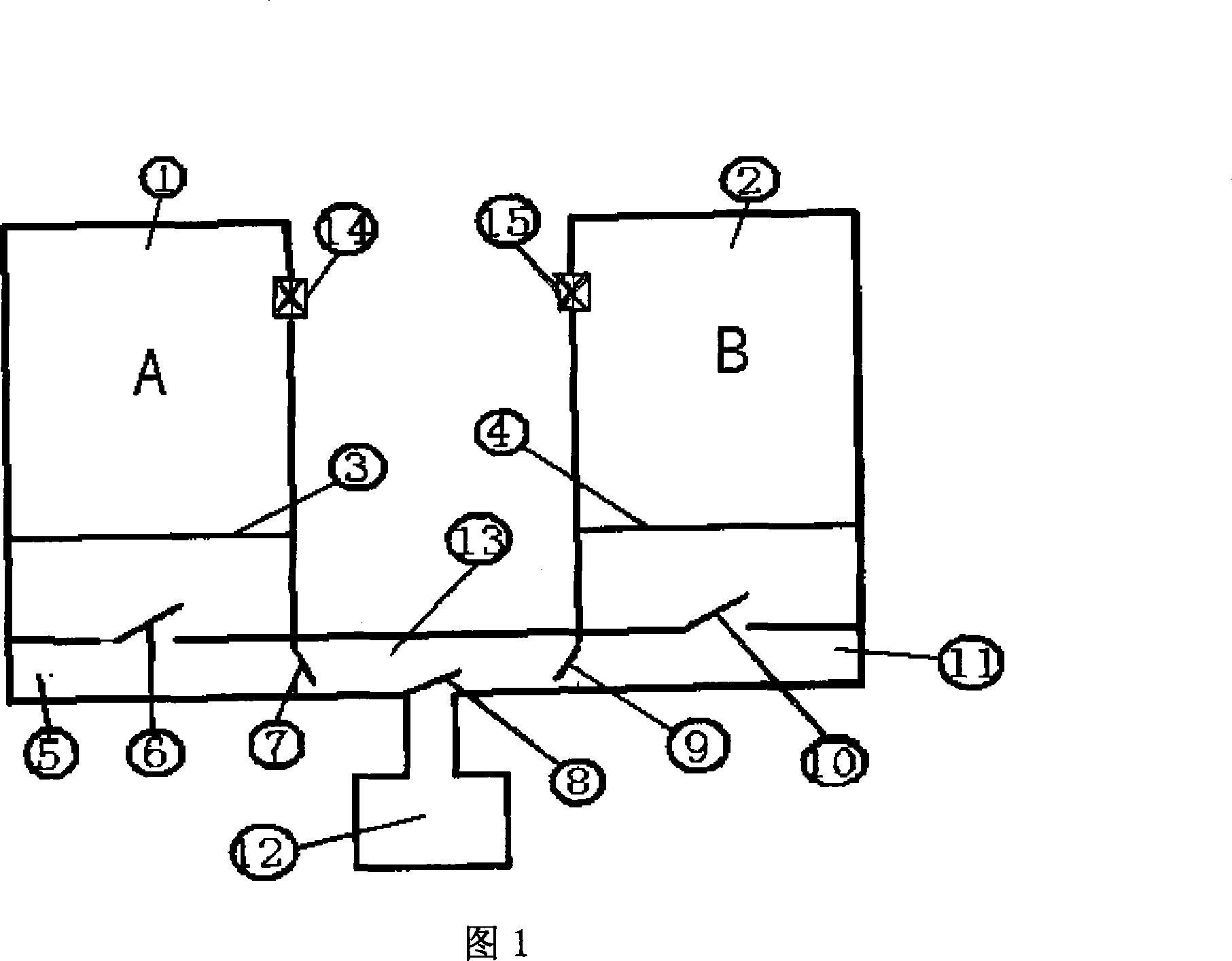

[0025] The invention provides an atomic layer deposition device and method with multiple reaction chambers. The main structure of the device is shown in Figure 1. The A reaction chamber 5 and the B reaction chamber 11 of the A reaction chamber and the B reaction chamber are respectively connected through the A channel valve 7, the B channel valve 9 and the transition chamber 13, and the transition chamber 13 passes through The vacuum pump valve 8 is connected to a group of vacuum pumps 12; the A reaction chamber, the A reaction chamber 5 is connected to the A storage chamber 1 through the A storage chamber vacuum valve 6 and the A storage chamber partition 3; the B reaction chamber, the B reaction chamber 11 passes through The vacuum valve 10 of the B storage chamber and the partition 4 of the B storage chamber communicate with the B storage chamber 2; the A reactant inlet valve 14 and the B reactant inlet valve 15 are respectively arranged on the upper part of the A storage chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com