Sleeve compensator special for thermal production well

A technology of thermal recovery wells and compensators, which is applied to casings, expansion compensation devices for pipelines, drill pipes, etc., can solve problems such as increased investment costs, inability to compensate casings, increased difficulty, etc., and reduce operating and construction costs , safe and convenient construction, and the effect of reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

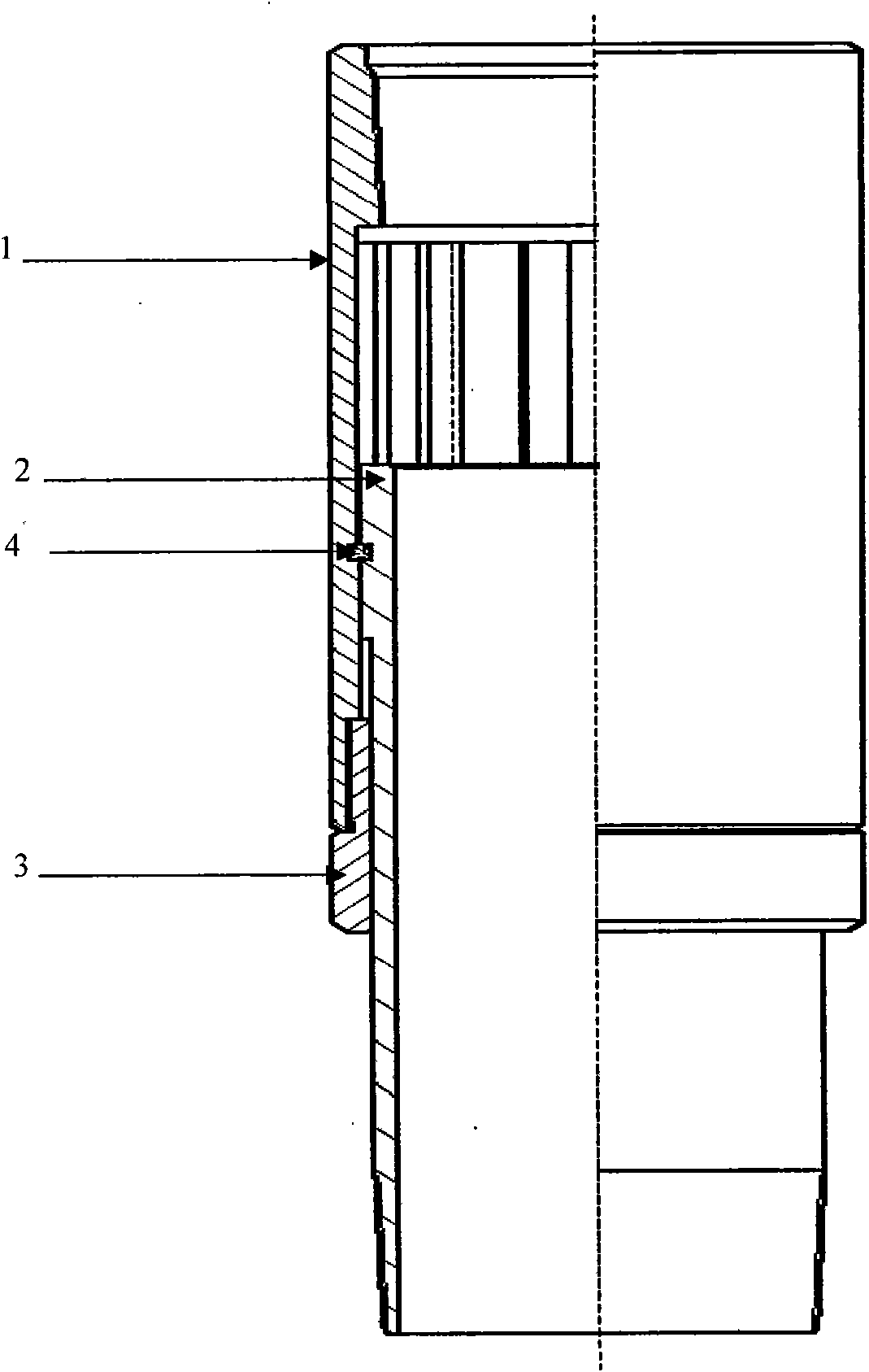

[0014] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings: Referring to the accompanying drawings, the special casing compensator for thermal recovery wells includes an outer cylinder 1 and a center pipe 2, the outer cylinder 1 is connected to the bottom cap 3, and the center pipe 2 and The outer cylinder 1 is connected by a spline, and a locking mechanism is also provided between the outer cylinder 1 and the central tube 2 . The upper part of the inner cavity of the outer cylinder 1 is a limit step, the middle part is provided with an internal spline and an annular locking groove, the lower part of the inner cavity is connected with the bottom cap 3, and the locking mechanism is filled in the annular locking groove, the groove depth of which is greater than The tooth root of the internal spline. The locking mechanism includes a locking block 4 and a hot-melt material, and the locking block 4 and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com