Method for extracting citric acidby employingcentrifugal extractor

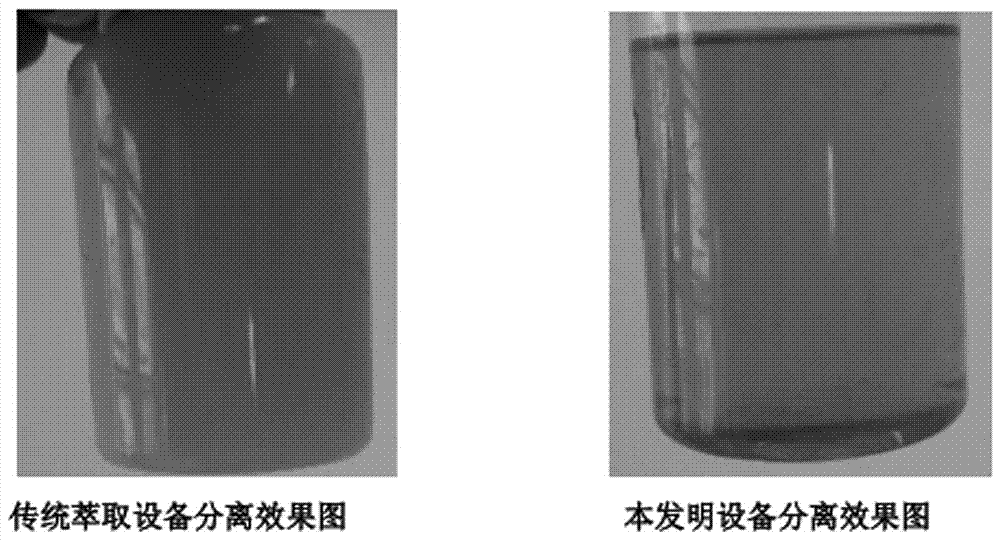

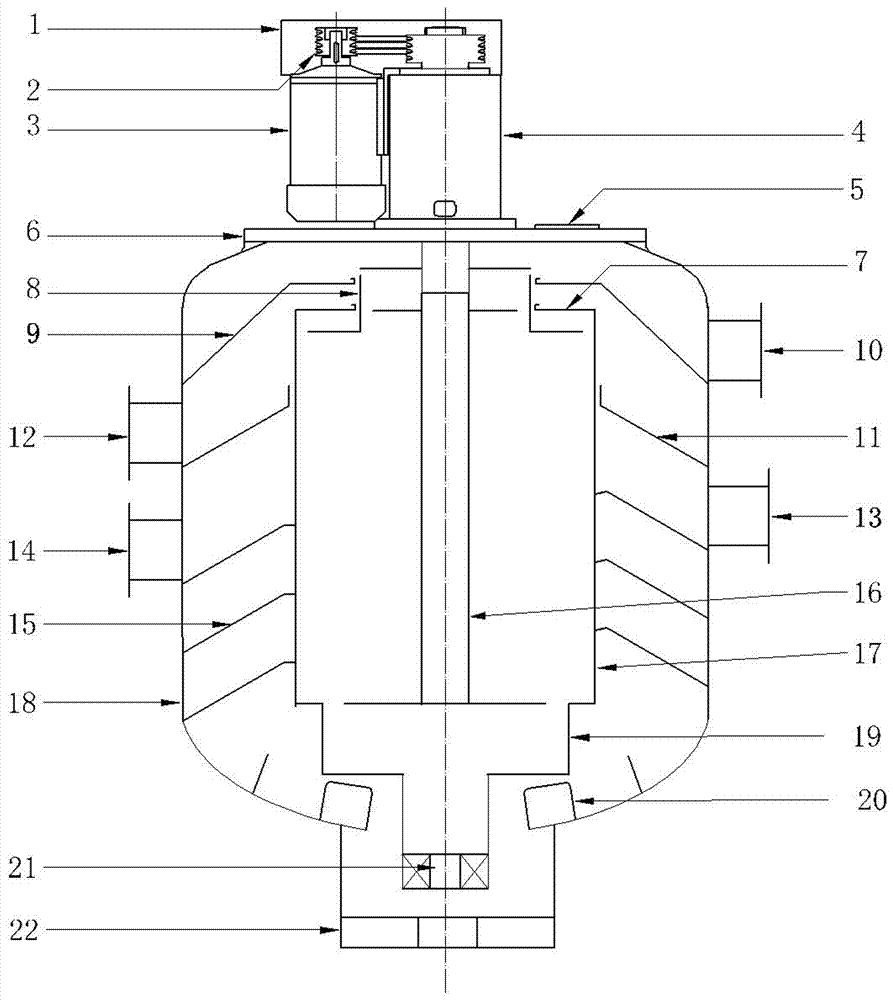

A centrifugal extractor and citric acid technology, applied in separation methods, solvent extraction, countercurrent extraction, etc., can solve the problems of low extraction rate and easy corrosion of containers, and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

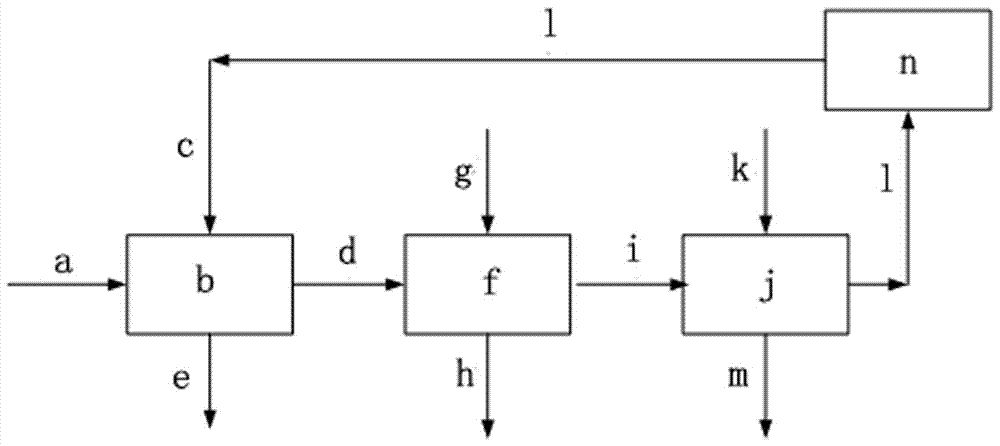

[0058] A method for extracting citric acid using a centrifugal extractor, comprising the following steps:

[0059] (1) Extraction section: using amines as extraction agents, put the citric acid fermentation broth into a centrifugal extractor to extract citric acid; the volume ratio of amine to crude citric acid is 1:1; the temperature is 35°C; 5-stage countercurrent extraction ; The amines are trilaurylamine: secondary amine: sulfonated kerosene, its volume ratio, trilaurylamine: secondary amine: sulfonated kerosene=2:2:6;

[0060] (2) Washing section: the organic phase containing citric acid in step (1) is placed in a centrifugal extractor for washing, the volume ratio of the organic phase to water is 10:1; the temperature is 35°C; 2-stage countercurrent extraction;

[0061] (3) stripping section: the organic phase gained in the step (2) is placed in a centrifugal extractor for stripping with water, and the organic phase is collected as a citric acid phase; the volume ratio o...

Embodiment 2

[0066] A method for extracting citric acid using a centrifugal extractor, comprising the following steps:

[0067] (1) Extraction section: using amines as extraction agents, put the citric acid fermentation broth into a centrifugal extractor to extract citric acid; the volume ratio of amine to crude citric acid is 5:1; the temperature is 30°C; 5-stage countercurrent extraction ; The amines are trilaurylamine: secondary amine: sulfonated kerosene, its volume ratio, trilaurylamine: secondary amine: sulfonated kerosene=2:2:6;

[0068] (2) Washing section: the organic phase containing citric acid in step (1) is placed in a centrifugal extractor for washing, the volume ratio of the organic phase to water is 25:1; the temperature is 30°C; 2-stage countercurrent extraction;

[0069] (3) stripping section: the organic phase gained in the step (2) is placed in a centrifugal extractor for stripping with water, and the organic phase is collected as a citric acid phase; the volume ratio o...

Embodiment 3

[0072] A method for extracting citric acid using a centrifugal extractor, comprising the following steps:

[0073] (1) Extraction section: using amines as extraction agents, put the citric acid fermentation broth into a centrifugal extractor to extract citric acid; the volume ratio of amine to crude citric acid is 6:1; the temperature is 33°C; 5-stage countercurrent extraction ; The amines are trilaurylamine: secondary amine: sulfonated kerosene, its volume ratio, trilaurylamine: secondary amine: sulfonated kerosene=2:2:6;

[0074] (2) Washing section: the organic phase containing citric acid in step (1) is placed in a centrifugal extractor for washing, the volume ratio of the organic phase to water is 30:1; the temperature is 33°C; 2-stage countercurrent extraction;

[0075] (3) stripping section: the organic phase gained in the step (2) is placed in a centrifugal extractor for stripping with water, and the organic phase is collected as a citric acid phase; the volume ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com