Method for high-temperature efficient aerobic composting of rural organic wastes

A technology of organic waste and aerobic composting, applied in the fields of organic fertilizer, energy industry, electric vehicles, etc., can solve the problems of incomplete harmlessness, long composting cycle, large area, etc., to improve the quality of rural living environment, The effect of high decomposing degree and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

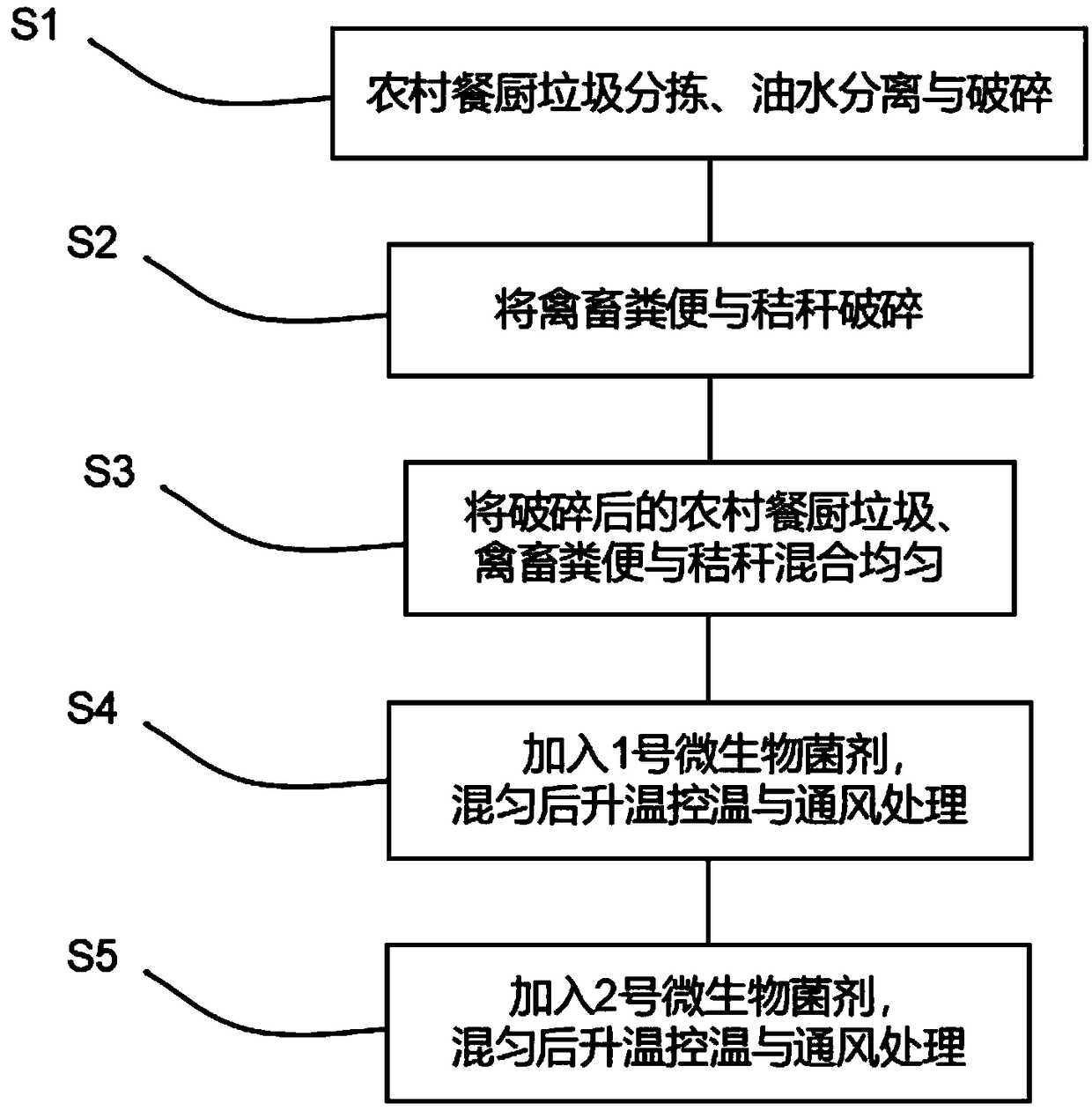

[0027] Such as figure 1 As shown, the present invention provides a kind of method of high-temperature high-efficiency aerobic composting of rural organic waste, comprising the following steps:

[0028] S1: Sorting rural kitchen waste, removing plastic, glass, and metal non-compostable objects, followed by oil-water separation, and breaking the separated solids to 12-60mm;

[0029] S2: Break poultry manure and crop straw to 12-60mm and 2-10mm respectively;

[0030] S3: Mix rural kitchen waste, poultry manure and straw evenly according to the mass ratio of 4:4:2 to form compost material, and control the C / N ratio of compost material at 35:1, the moisture content is 55%, and the pH value is 7;

[0031] S4: Add 5% No. 1 microbial agent to the compost material, mix evenly, carry out temperature control and ventilation treatment on the mixture, enter the pre-fermentation stage, and the composting time is 12h;

[0032] S5: Add 5% of No. 2 microbial agent to the compost material, m...

Embodiment 2

[0038] Such as figure 1 As shown, the present invention provides a kind of method of high-temperature high-efficiency aerobic composting of rural organic waste, comprising the following steps:

[0039] S1: Sorting rural kitchen waste, removing plastic, glass, and metal non-compostable objects, followed by oil-water separation, and crushing the separated solids to 12-60mm;

[0040] S2: Break poultry manure and crop straw to 12-60mm and 2-10mm respectively;

[0041] S3: Mix rural kitchen waste, poultry manure and straw according to the mass ratio of 5:3:2 to form compost material, and control the C / N ratio of compost material at 25:1, the moisture content is 55%, and the pH value is 6;

[0042] S4: Add 8% No. 1 microbial bacterial agent to the compost material, mix evenly, carry out temperature control and ventilation treatment to the mixture, enter the pre-fermentation stage, and the composting time is 8h;

[0043] S5: Add 8% of the No. 2 microbial agent to the compost mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com