Comprehensive recovering method for tailings containing precious metal

A recovery method and precious metal technology, applied in the direction of improving process efficiency, can solve the problems of secondary environmental pollution and low recovery rate, and achieve the effect of effective recovery, clean process and environmental protection, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

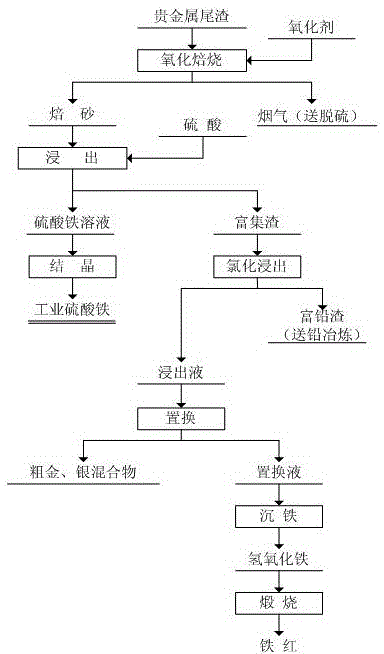

Embodiment 1

[0022] A method for comprehensive recovery of tailings containing precious metals, specifically comprising the following steps: take 1000g of tailings containing gold, lay them flat in a muffle furnace, continuously feed 5% oxygen, control the roasting temperature at 500°C for 0.5h, and bake the sand Cool to 80°C, after the calcine is cooled, control the leaching liquid-solid ratio to 2:1, the mass fraction of sulfuric acid is 5%, the dosage of sodium persulfate is 20g / L, the reaction temperature is 60°C, react for 2h, filter, evaporate and crystallize the filtrate to obtain ferric sulfate solution, evaporate Back leaching of the mother liquor, control the leaching liquid-solid ratio of the filter residue to 2:1, mass fraction of sulfuric acid 10%, sodium chloride dosage 20g / L, reaction temperature 80°C, react for 4 hours, filter, filter residue is sold as lead-rich slag, and the filtrate is obtained by replacing it with iron powder The gold and silver mixed precipitate is sent...

Embodiment 2

[0025] A method for comprehensive recovery of tailings containing precious metals, specifically comprising the following steps: take 1000g of tailings containing gold, lay them flat in a muffle furnace, continuously feed 15% oxygen, control the roasting temperature at 1000°C for 6 hours, and cool the calcination To 150°C, after cooling the calcine, control the leaching liquid-solid ratio to 8:1, the mass fraction of sulfuric acid is 20%, the dosage of ammonium persulfate is 50g / L, the reaction temperature is 60°C, react for 2h, filter, evaporate and crystallize the filtrate to obtain ferric sulfate solution, and evaporate the mother liquor Back leaching, filter residue control leaching liquid-solid ratio 3:1, mass fraction of sulfuric acid 30%, sodium chloride dosage 200g / L, reaction temperature 80°C, react for 4h, filter, filter residue is sold as lead-rich residue, filtrate is replaced with iron powder to obtain gold Silver and silver mixed precipitates are sent to the precio...

Embodiment 3

[0028] A comprehensive recovery method for tailings containing precious metals, specifically comprising the following steps: taking tailings containing precious metals, laying them flat in a muffle furnace, introducing oxygen with a mass percentage of 8% of the tailings containing precious metals, and controlling the roasting temperature to 600°C for 3 hours , the calcined sand is cooled to 120°C; the calcined sand and sulfuric acid with a mass fraction of 10% are added to the calcined sand with sulfuric acid at a solid-to-liquid mass ratio of 1:4, and 35 g / L of sodium persulfate is added to the mixture of calcined sand and sulfuric acid, At 90°C, react for 4 hours, leaching, and filter to obtain the enriched residue of the filter residue and the ferric sulfate solution of the filtrate. The filtrate is evaporated and crystallized to obtain industrial ferric sulfate. Add sulfuric acid with a mass fraction of 20% to the enriched residue at a solid-to-liquid mass ratio of 1:3 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com