Method for recovering valuable elements in gold-silver-iron associated ore tailings

A technology of valuable elements and recycling methods, applied in the direction of improving process efficiency, etc., can solve the problems of low added value of products, low comprehensive utilization rate of valuable elements, backward technology, etc., to save construction investment and equipment costs, and benefit Safe and environmentally friendly production and the effect of reducing the workload of cyanide leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

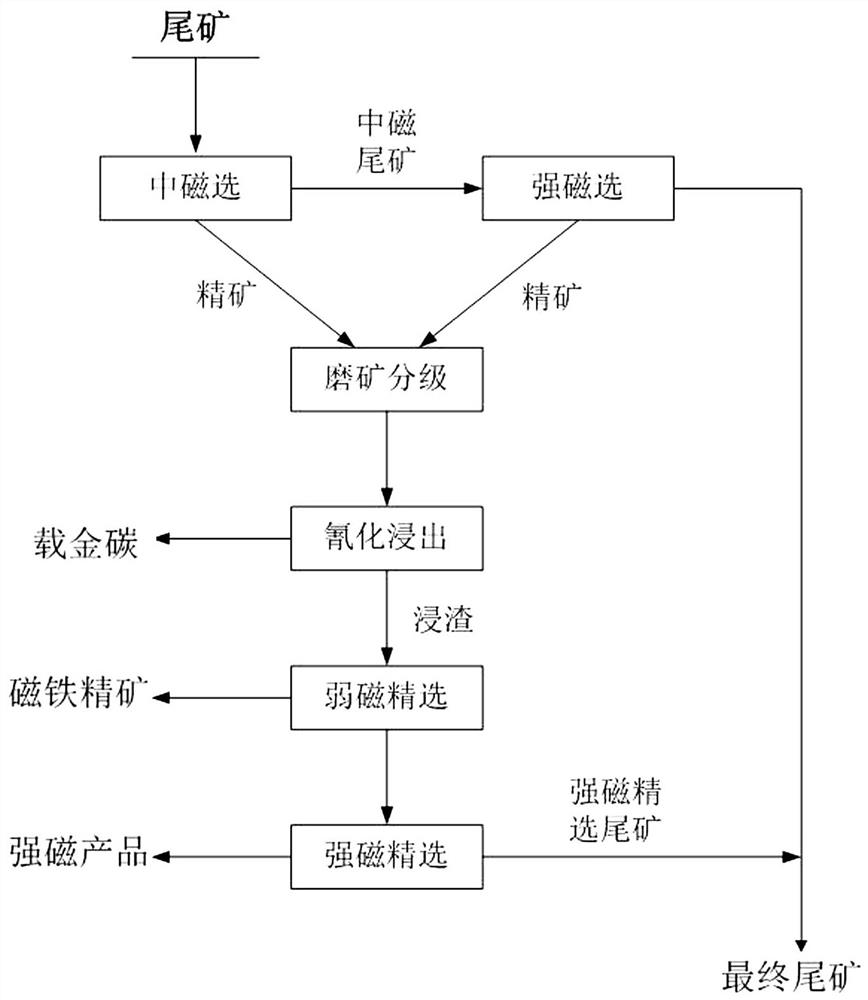

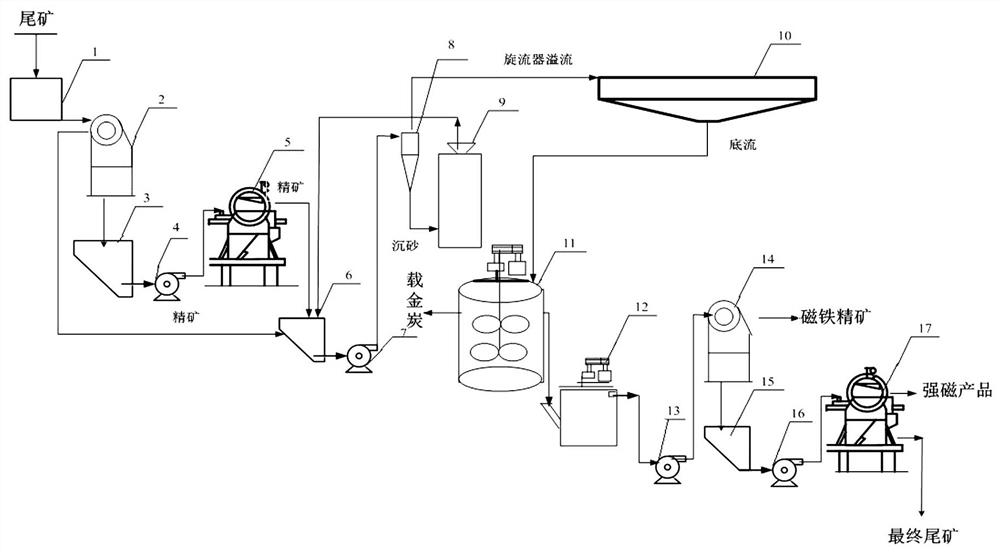

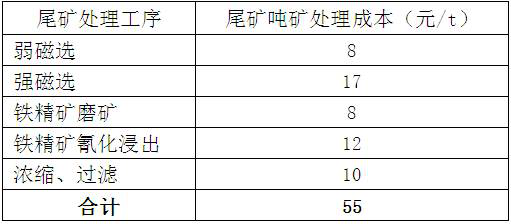

Method used

Image

Examples

Embodiment 1

[0043] The test tailings sample (ore slurry) was taken from a gold-silver co-associated sulfide ore (copper ore) beneficiation tailings in Yunnan. The chemical multi-element analysis of the tailings showed that the grade of iron was 22.41%, the grade of gold was 0.30g / t, and the grade of silver was 22.41%. The grade is 6.01g / t, and the magnet content in the tailings varies between 2% and 3%. The research results of tailings process mineralogy show that gold is mainly dispersed in pyrite, magnetite, brown Iron ore, siderite and gangue minerals; silver is mainly dispersed in pyrite, magnetite, limonite, siderite and gangue minerals as fine inclusions of silver minerals; iron minerals in tailings are mainly siderite Ore, followed by limonite, and a small amount of magnetite and pyrite; iron minerals are the main carrier minerals of gold and silver. Therefore, gold-silver-loaded iron ore will be the main sorting and recycling objects.

[0044] After the tailings slurry is adjuste...

Embodiment 2

[0054] The test tailings sample (ore slurry) was taken from a gold-silver co-associated sulfide ore (lead-zinc ore) beneficiation tailings in Yunnan. The chemical multi-element analysis of the tailings showed that the iron grade was 18.19% (magnetic iron grade) and the gold grade was 0.26 g / t, the silver grade is 6.32g / t, and the magnetite content in the tailings varies between 2% and 3%. Limonite, siderite, hematite and gangue minerals; silver is mainly dispersed in magnetite, limonite, siderite, hematite and gangue minerals as fine inclusions of silver minerals; iron in tailings The minerals are mainly siderite, followed by limonite, hematite, and a small amount of magnetite and pyrite; iron minerals are the main carrier minerals of gold and silver. Therefore, gold-silver-loaded iron ore will be the main sorting and recycling objects.

[0055] After the tailings slurry is adjusted to a concentration of 25-30%, it enters the magnetic separation operation, and the wet permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com