Device for processing using leaves

A leaf and sieving technology, applied in the removal of solid waste, fixed filter element filter, filtration and separation, etc., can solve the problems of secondary pollution, inability to use waste, etc., to prevent blockage, effectively recycle and reduce waste. The effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

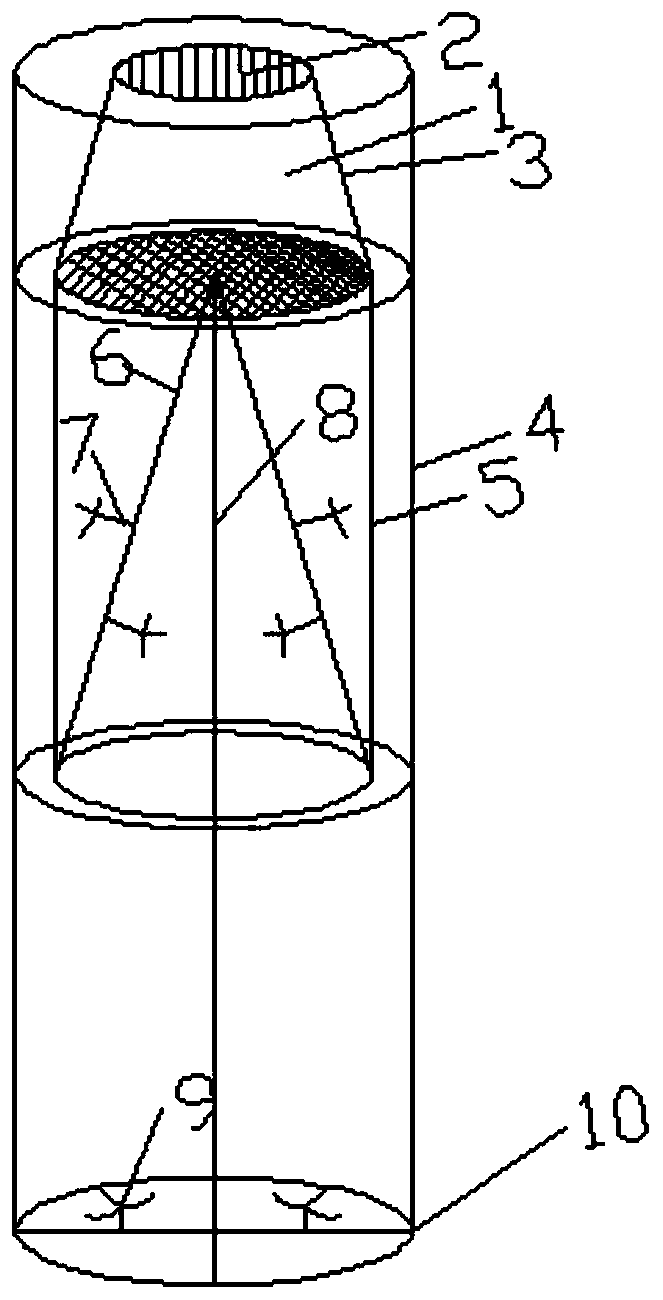

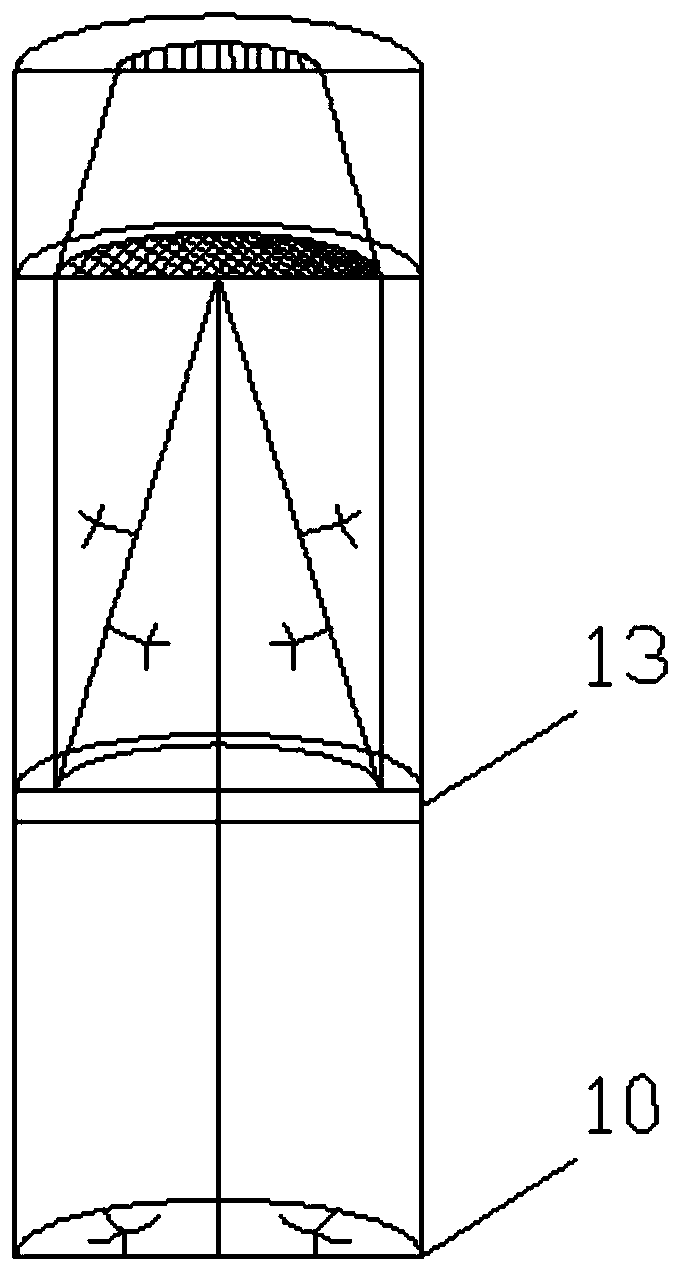

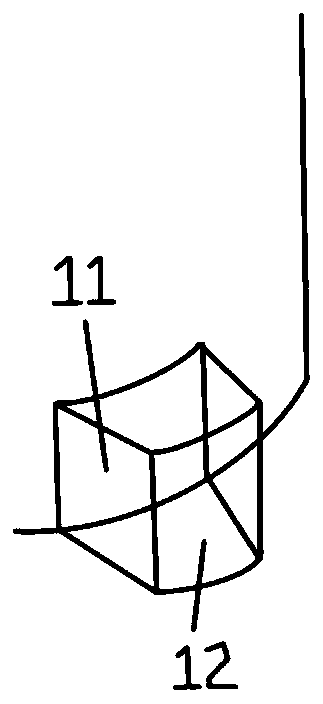

[0032] A machine for processing and utilizing leaves mainly includes an inlet channel 1, a sieving machine 4, and a crushing machine 10, the inlet channel 1 is provided with a transverse comb-shaped bayonet 2, and the inlet channel 1 and the sieving machine 4 are connected, the entrance channel 1 is set on the upper side of the screening machine 4, the screening machine 4 is set as a double-layer structure, the outer layer 4 is a closed cylindrical structure around, and the inner layer 5 is a fully enclosed fine mesh shape structure, and the mesh structure at the lower part of the inner layer can be opened, and the leaves sieved out are transferred to the crushing machine 10, which is a closed circle with several serrated blades 9 that can rotate at high speed at the bottom. Cylindrical structure.

[0033] The entrance channel 1 is provided with a horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com