Method for refining iron based on copper smelting waste residues

A waste slag and copper smelting technology, applied in the direction of fluidized bed furnace, etc., can solve the problems of waste of secondary resources, difficulty in refining, low grade, etc., and achieve the effect of improving utilization rate and effective recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

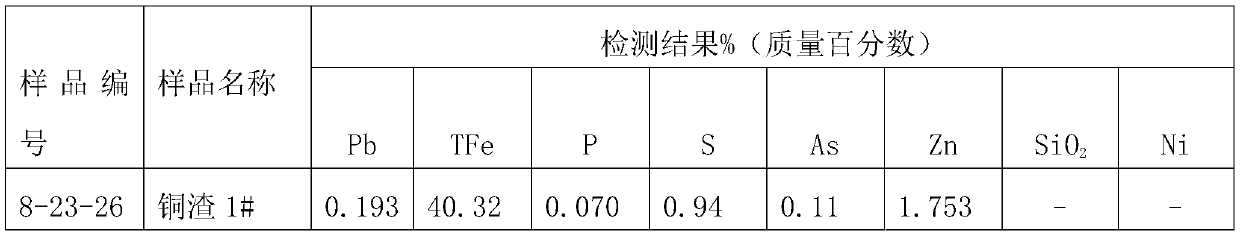

Embodiment 1

[0023] A method for refining iron based on copper smelting waste slag, comprising the steps of:

[0024] Crushing: After crushing the copper smelting waste slag, the crushed waste slag is obtained;

[0025] Magnetic separation: After the crushed waste residue is magnetically separated and crushed, waste residue particles are obtained;

[0026] Mixing material: Mix the reducing agent, flux, catalyst and waste slag particles evenly to make smelting particles;

[0027] Smelting: After the smelting particles are dried and sent to the melting pool of the refining furnace for smelting, slag and molten iron are obtained;

[0028] Slagging: After adding reducing agent and impurity removing agent to the molten pool for slagging reaction, the impurity-removing molten iron is obtained;

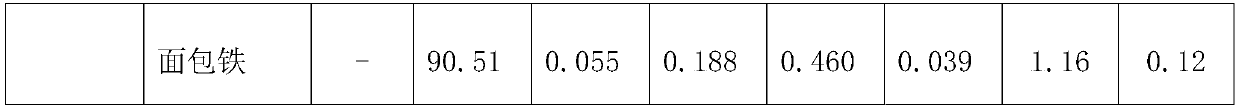

[0029] Preparation of Bread Iron: Treat the molten iron with impurities removed with a cast iron machine to obtain Bread Iron.

[0030] Further, the reducing agent is coke powder; the flux is calcium ...

Embodiment 2

[0036] A method for refining iron based on copper smelting waste slag, comprising the steps of:

[0037] Crushing: After crushing the copper smelting waste slag, the crushed waste slag is obtained;

[0038] Magnetic separation: After the crushed waste residue is magnetically separated and crushed, waste residue particles are obtained;

[0039] Mixing material: Mix the reducing agent, flux, catalyst and waste slag particles evenly to make smelting particles;

[0040] Smelting: After the smelting particles are dried and sent to the melting pool of the refining furnace for smelting, slag and molten iron are obtained;

[0041] Slagging: After adding reducing agent and impurity removing agent to the molten pool for slagging reaction, the impurity-removing molten iron is obtained;

[0042] Preparation of Bread Iron: Treat the molten iron with impurities removed with a cast iron machine to obtain Bread Iron.

[0043] Further, the reducing agent is coke powder; the flux is calcium ...

Embodiment 3

[0049] A method for refining iron based on copper smelting waste slag, comprising the steps of:

[0050] Crushing: After crushing the copper smelting waste slag, the crushed waste slag is obtained;

[0051] Magnetic separation: After the crushed waste residue is magnetically separated and crushed, waste residue particles are obtained;

[0052] Mixing material: Mix the reducing agent, flux, catalyst and waste slag particles evenly to make smelting particles;

[0053] Smelting: After the smelting particles are dried and sent to the melting pool of the refining furnace for smelting, slag and molten iron are obtained;

[0054] Slagging: After adding reducing agent and impurity removing agent to the molten pool for slagging reaction, the impurity-removing molten iron is obtained;

[0055] Preparation of Bread Iron: Treat the molten iron with impurities removed with a cast iron machine to obtain Bread Iron.

[0056] Further, the reducing agent is coke powder; the flux is calcium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com