Method for preparing metal chelating agent from glass fiber waste by modification and application of metal chelating agent

A metal chelating agent, glass fiber technology, applied in the directions of alkali metal compounds, non-metal elements, chemical instruments and methods, etc., can solve the problems of low recovery and treatment efficiency, difficult regeneration, cumbersome operation, etc., and achieve the effect of effective recovery and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

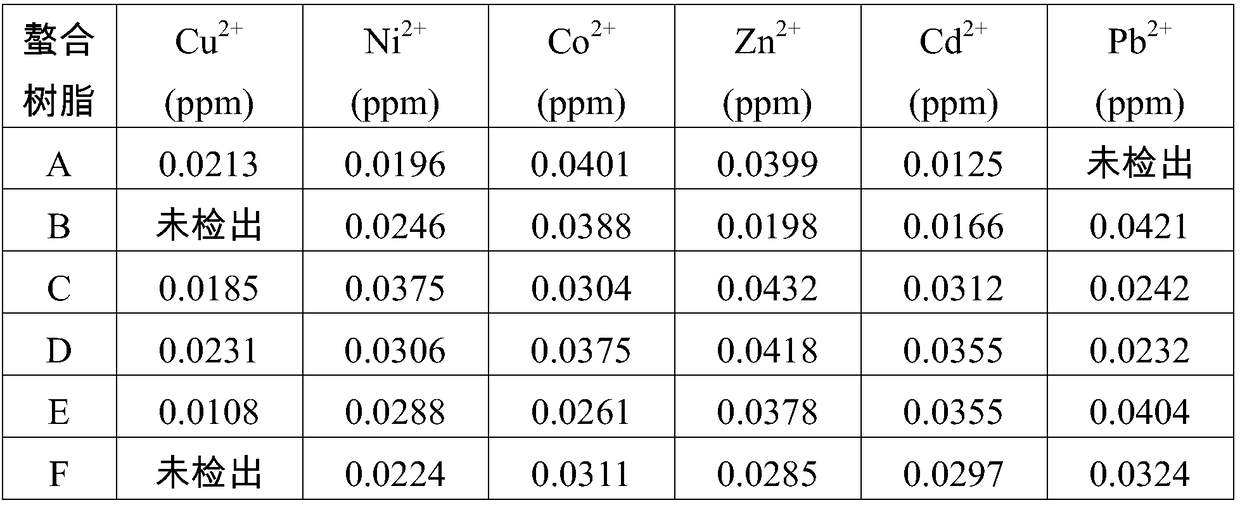

Examples

Embodiment 1

[0023] The glass fiber waste modification prepares the method for metal chelating agent, comprises the following steps:

[0024] (1) Pretreatment: Take 100g of waste glass fiber solid powder, wash it twice with water, and filter; then add the filter cake to 500mL NaOH solution with a concentration of 0.5mol / L and boil for 30min, filter, wash with water until neutral, filter ; Then add 500mL concentration of filter cake to be the HNO of 0.5mol / L 3 Boil in the solution for 30 minutes, filter, wash with water until neutral, filter, and dry the filter cake at 100°C to obtain pretreated glass fiber powder;

[0025] (2) Amination reaction: Take 30 g of pretreated glass fiber waste in step (1) and add it to a flask, add 100 mL of solvent water to the flask, and then add 15 mL of amination modifier γ-(methacryloyloxy)propane Aminated with trimethoxysilane, then stirred at a speed of 200r / min, condensed and refluxed, stirred and reacted at 60°C for 8h, after the reaction was completed...

Embodiment 2

[0028] The method for preparing metal chelating agent by glass fiber waste modification comprises the following steps:,

[0029] (1) Pretreatment: Take 150g of glass fiber powder as solid powder and wash it with water for 3 times, filter; then add 600mL of Na 2 CO 3 Boil in the solution for 30min, filter, wash with water until neutral, filter; then add the filter cake to 600mL HCl solution with a concentration of 0.5mol / L, boil for 30min, filter, wash with water until neutral, filter, and dry the filter cake at 100°C , to obtain pretreated glass fiber powder;

[0030] (2) Amination reaction: Take 40 g of pretreated glass fiber waste in step (1) and add it to the flask, add 200 mL of the first solvent toluene to the flask, and then add 50 mL of the amination modifier γ-mercaptopropyltrimethoxy Aminated silane, then stirred at a speed of 200r / min, condensed and refluxed, stirred and reacted at 70°C for 10h, after the reaction was completed, washed with water and ethanol in seq...

Embodiment 3

[0033] The glass fiber waste modification prepares the method for metal chelating agent, comprises the following steps:

[0034] (1) Pretreatment: Take 300 g of glass fiber waste powder, wash it with water for 3 times, and filter; then add the filter cake to 1000 mL of KOH solution with a concentration of 1 mol / L, boil for 30 min, filter, wash with water until neutral, and filter; Then the filter cake was added with 1000mL concentration of 0.7mol / L H 2 SO 4 Boil in the solution for 20 minutes, filter, wash with water until neutral, filter, and dry the filter cake at 110°C to obtain pretreated glass fiber powder;

[0035](2) Amination reaction: Take 50 g of pretreated glass fiber waste in step (1) and add it to the flask, add 500 mL of the first solvent methanol to the flask, and then add 80 mL of the amination modifier γ-chloropropyl trimethoxy Aminated silane, then stirred at a speed of 400r / min, condensed and refluxed, stirred and reacted at 100°C for 12h, after the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com