Filling machine

A technology of filling machine and driving device, which is applied in the field of extrusion device for making sausages, and can solve problems such as waste, hidden hygiene hazards left over, and food material pushing out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

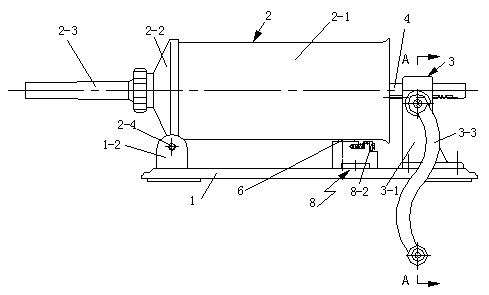

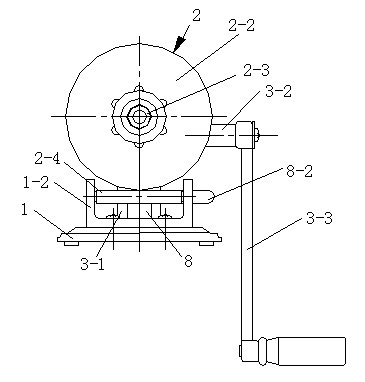

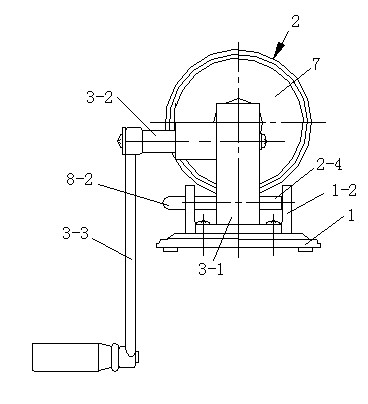

[0050] Such as Figure 1~14 As shown, the filling machine of the present invention includes a barrel 2, a piston 7, a piston rod 4, a base 1 and a piston rod driving device 3, the front end of the barrel 2 has a cone bucket 2-2, and the piston 7 and the piston rod 4. Fixed connection, the piston 7 is slidingly matched with the inner wall of the barrel 2, and the piston rod driving device 3 is connected to the piston rod 4 through transmission. Compatible with the cone wall.

[0051] Such as Figure 7 , 8 , 9, 10, 11, 12, 13, and 14, in order to ensure food hygiene, the piston 7 includes a piston body 7-2, and the outer surface of the piston body 7-2 is covered with a silica gel layer 7-4. Certainly, the outer surface of the piston body 7-2 may not be coated with the silica gel layer 7-4.

[0052] Such as Figure 11 , 12 , 13, and 14, in order to make the connection between the silica gel layer 7-4 and the piston body 7-2 more firm, the piston body 7-2 also has several th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com