Device and method for high polymer material burning harmless treatment

A polymer material, harmless treatment technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problems of surrounding environmental pollution, inability to solve clean emissions, inability to achieve, and achieve harmless clean emissions, eliminate Health hazards and pollution reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

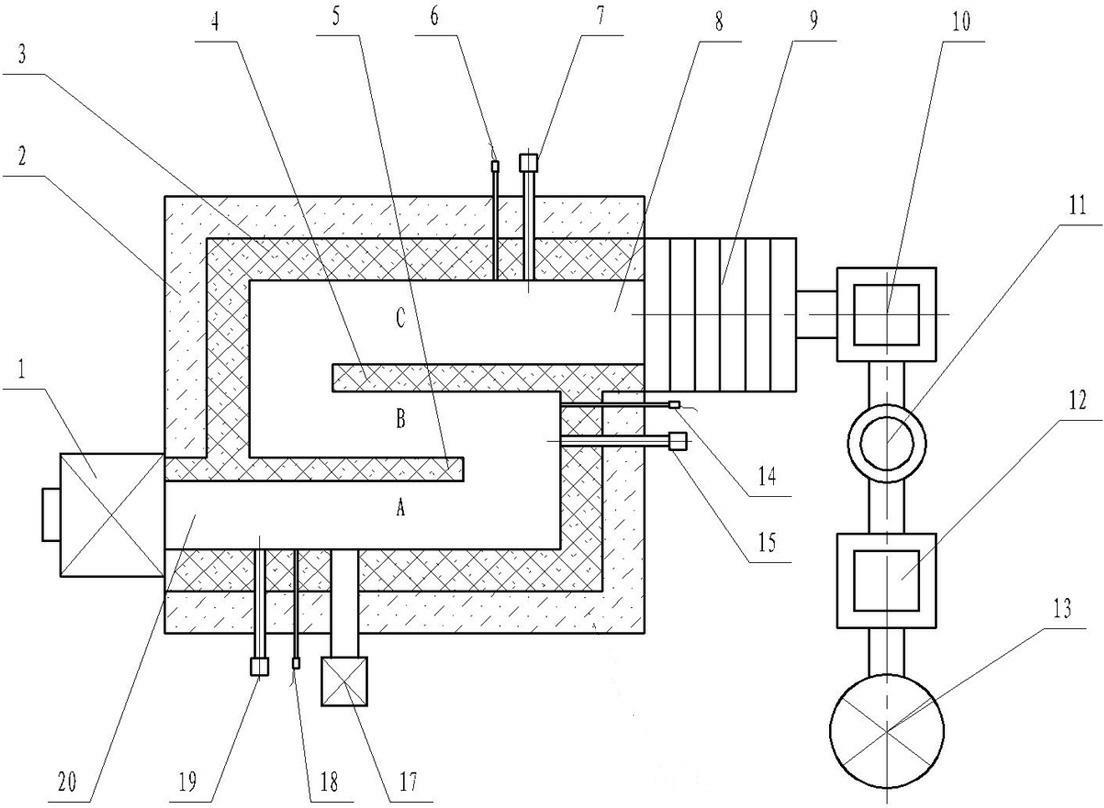

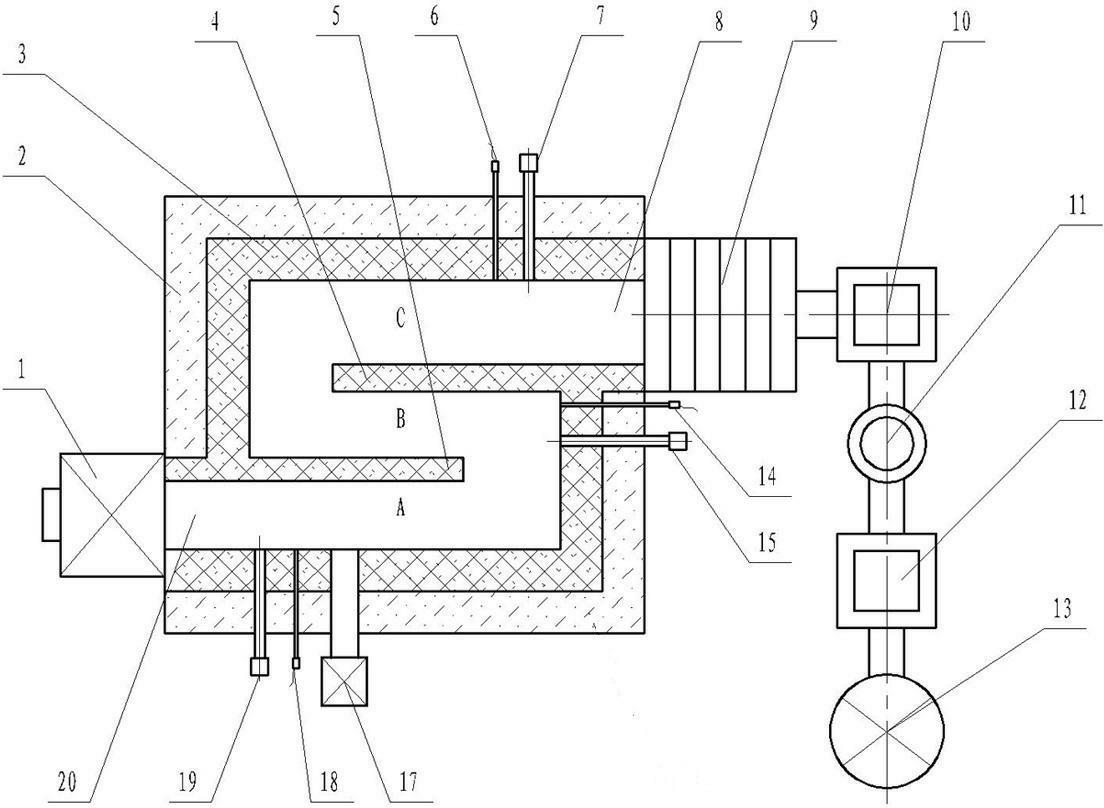

[0010] exist figure 1 Among them, a high-temperature pyrolysis tunnel kiln 3 with an insulating layer 2 is connected between the incinerator 1 and the heat exchange device 9 . The flue gas inlet 20 of the tunnel kiln 3 made of high temperature resistant material is connected with the flue gas outlet of the incinerator 1 . The flue gas outlet 8 of the tunnel kiln 3 is connected with a heat exchange device 9 . The tunnel in the tunnel kiln 3 is separated into three S-shaped tunnel cavities A, B, and C by a front partition wall 5 made of a high-temperature-resistant material and a rear partition wall 4 made of a high-temperature-resistant material. A kiln fan 19 , a kiln temperature measuring device 18 and an external heating source 17 are installed at the smoke inlet 20 of the tunnel kiln 3 . An air excess measuring device 7 and a kiln tail temperature measuring device 6 are installed at the smoke outlet 8 of the tunnel kiln 3 . A tunnel temperature measuring device 14 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com