Manufacturing method of carbon-silver composite target for curved touch screen

A composite target material and manufacturing method technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as touch screen failure, and achieve improved dispersion uniformity, good uniformity, and good bending resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for manufacturing a carbon-silver composite target for a curved touch screen of the present invention comprises the following steps:

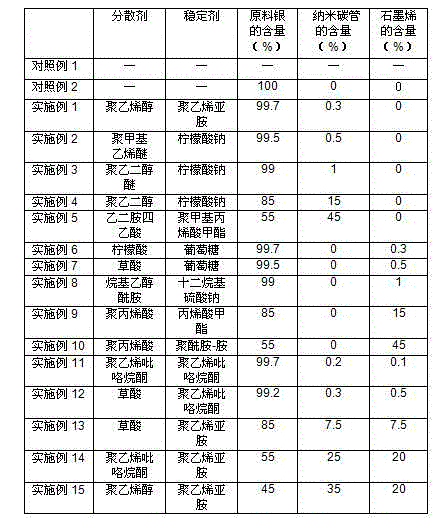

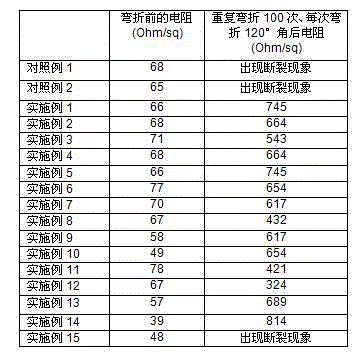

[0028] (1) Disperse the carbon material aqueous solution with ultra-high-speed shear force, then add silver salt, dispersant and stabilizer to the carbon material aqueous solution, heat to 60~90°C, and keep the temperature for 10~120min to obtain the reaction solution. The silver ions in the liquid are evenly precipitated on the surface of the carbon material; the dispersant is any one of polyvinylpyrrolidone, polyvinyl alcohol, polymethyl vinyl ether, polyacrylic acid, or any non-ionic surface active agent, or any chelating agent; the stabilizer is any one of polyethylenimine, sodium citrate, glucose, sodium lauryl sulfate, polyvinylpyrrolidone, or any dendrimer ;

[0029] (2) Freeze-drying the reaction liquid, removing the solvent, and obtaining carbon material powder with nano-silver particles adsorbed on the surface;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com