Low-thermal-conductivity spinel refractory homogeneous brick as well as preparation method and application thereof

A spinel-based, low thermal conductivity technology, applied in the field of refractory materials, can solve the problems of low thermal conductivity, high temperature load resistance, etc., and achieve stable high temperature performance, low thermal conductivity, high temperature load resistance and good erosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method for preparing low thermal conductivity spinel refractory homogeneous bricks described in the above technical solution, comprising the following steps:

[0035] performing the first mixing of magnesia particles, magnesia-alumina spinel particles and lightweight hollow spheres to obtain a first mixed material;

[0036] performing a second mixing of the first mixed material and a binder to obtain a second mixed material;

[0037] The second mixed material, magnesia fine powder and additive fine powder are mixed for the third time to obtain the third mixed material;

[0038] The third mixed material is sequentially pressed and fired to obtain a low thermal conductivity spinel refractory homogeneous brick.

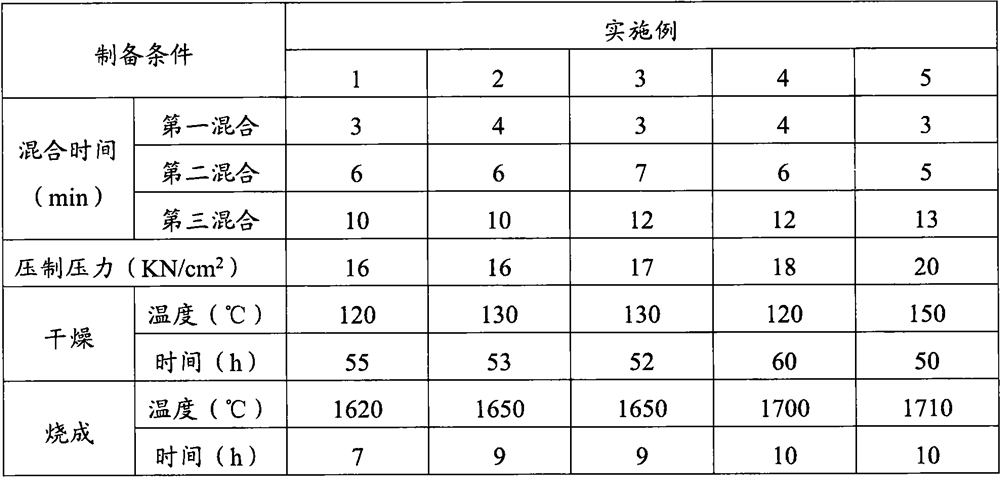

[0039] In the invention, the magnesia particles, the magnesium-aluminum spinel particles and the light hollow spheres are first mixed to obtain the first mixed material. In the present invention, the time for the first mixing is ...

Embodiment 1~5

[0048] Magnesia particles, magnesium aluminum spinel particles and lightweight hollow spheres (density ≤ 1.3g / cm 3 , hollow ratio ≥ 99%) is placed in the mixer, and the first mixing is carried out under the condition that the stirring rotor speed is 200rpm to obtain the first mixed material;

[0049] The first mixed material and the binder are mixed for the second time under the condition that the rotating speed of the stirring rotor is 200rpm to obtain the second mixed material;

[0050] The second mixed material, magnesia fine powder and additive fine powder are mixed for the third time under the condition that the stirring rotor speed is 200rpm to obtain the third mixed material;

[0051] Pressing the third mixed material, drying the obtained green body and firing it in a high-temperature tunnel kiln to obtain a spinel refractory homogeneous brick with low thermal conductivity;

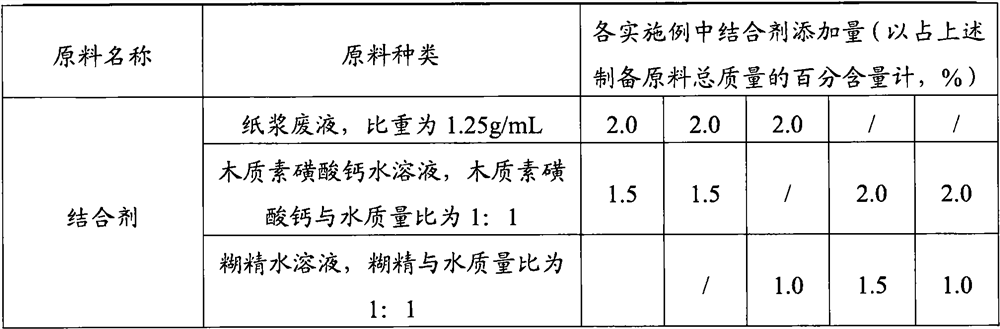

[0052] The raw materials and addition amounts used in the preparation of low thermal conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com