Hot winding solid corrugated pipe, sectional material thereof and manufacturing method thereof

A corrugated pipe and profile technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of poor resistance to damage, cumbersome production methods, and engineering accidents that destroy pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

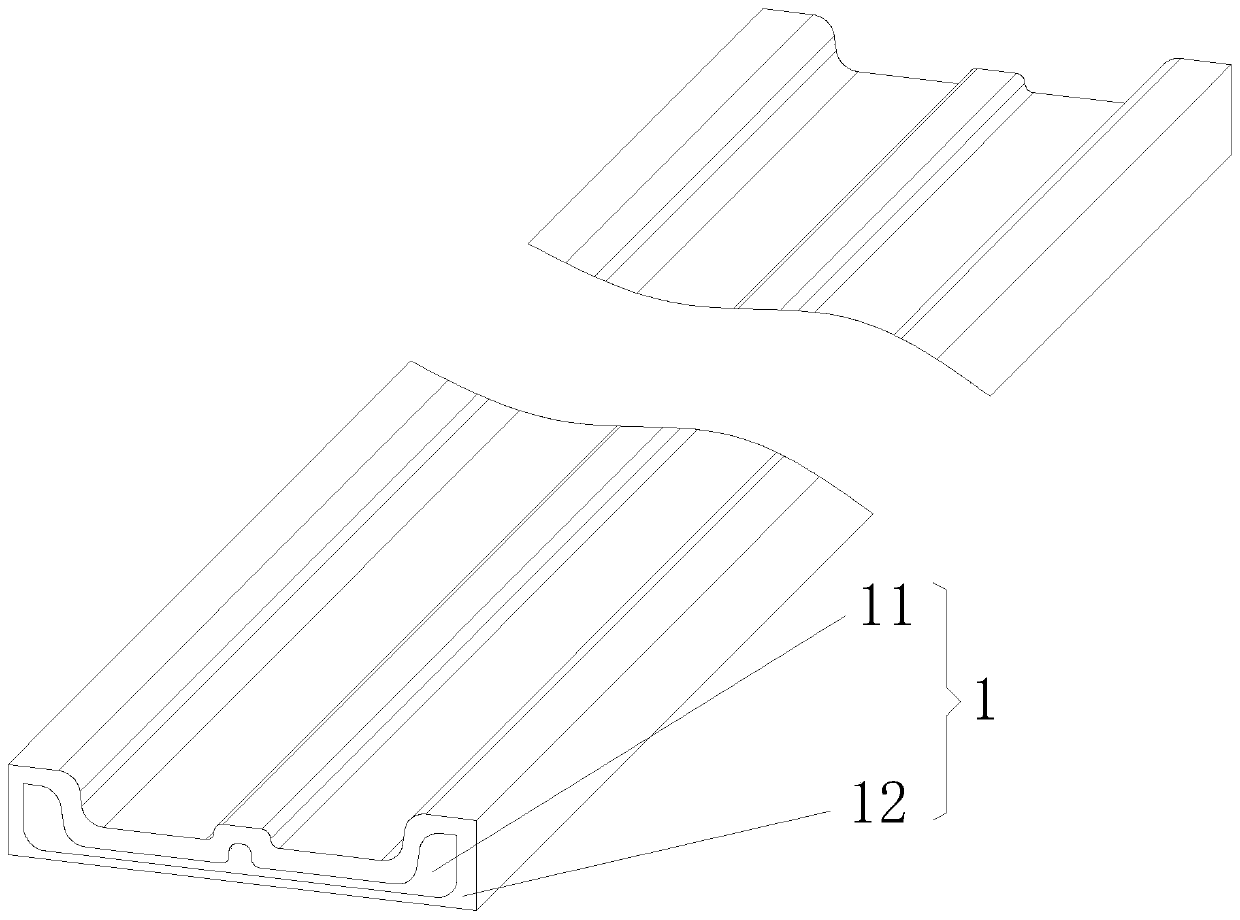

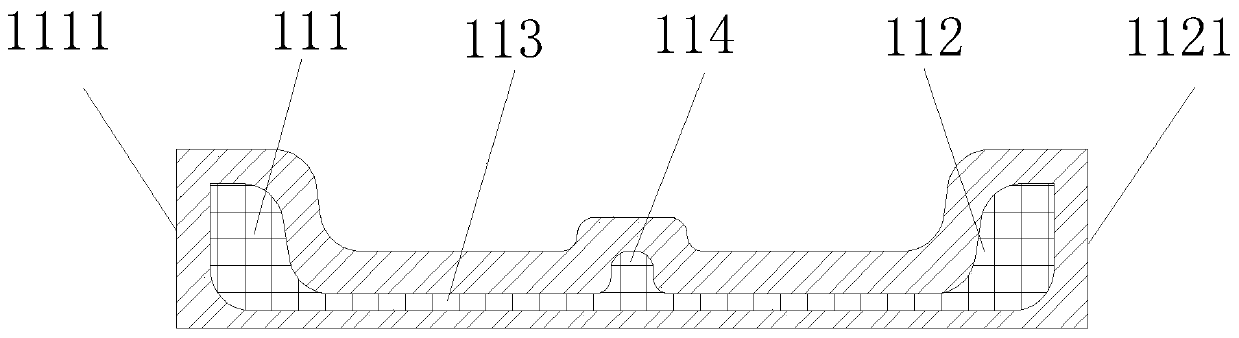

[0065] Such as Figure 1-10 As shown, a hot-wrapped solid corrugated pipe profile is characterized in that it includes a first profile 1 and a second profile 2 extending straight in the longitudinal direction; the first profile 1 includes a solid support rib 11 and a package The first thermal coating layer 12 on the outer wall of the supporting rib 11; in a cross section cut transversely along the first profile 1, the first profile 1 includes a connecting strip 113 located in the middle and horizontally arranged transversely, and a fixed The first half-wave crest bar 111 at one lateral end of the connecting bar 113 and the second half-wave crest bar 112 fixed at the other lateral end of the connecting bar 113; the top position of the first half crest bar 111 and the second half crest bar 112 The top positions of the first half wave crest bar 111 are horizontally connected to the horizontal end of the bottom of the connecting bar 113, and the bottom of the second half wave crest...

Embodiment 2

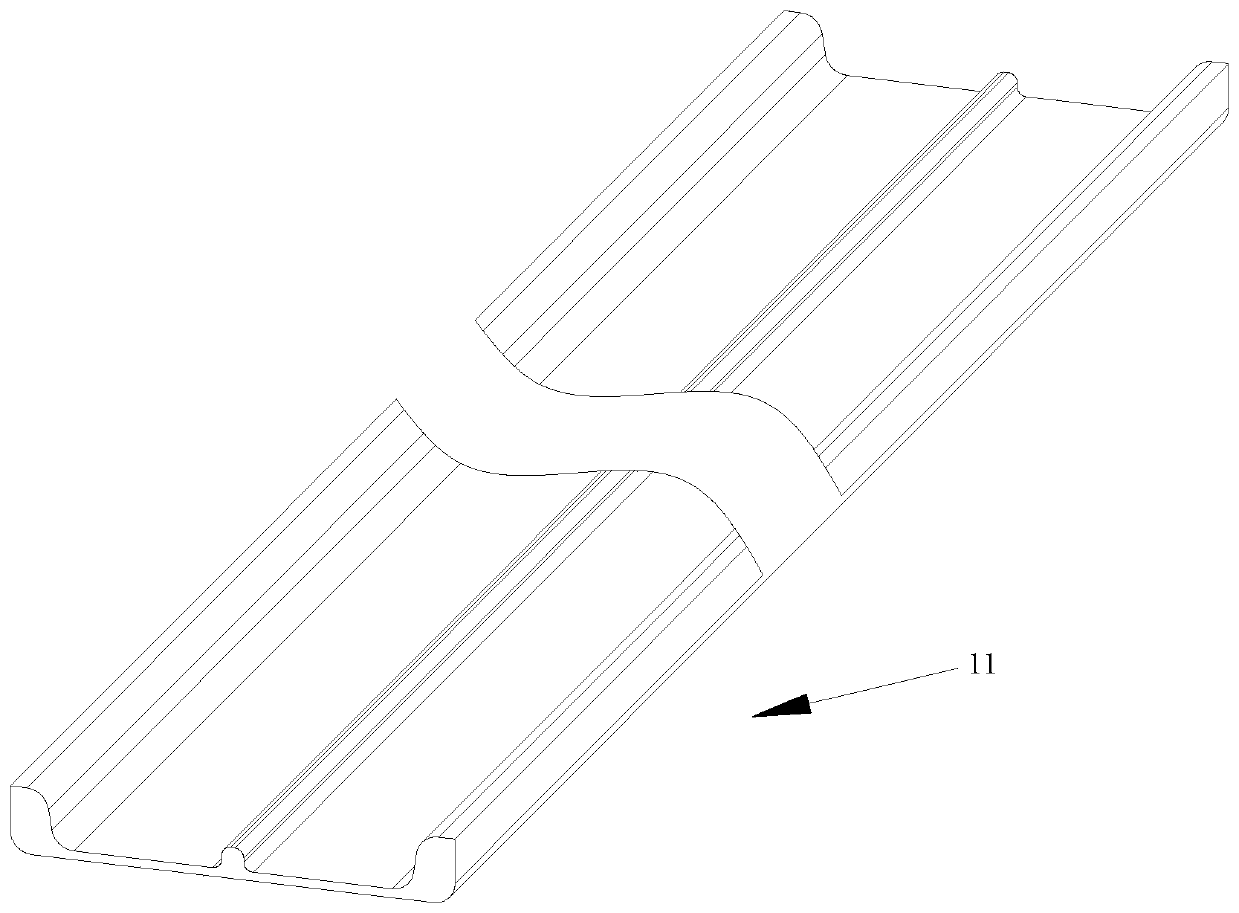

[0069] Such as Figure 1-10 As shown, a hot-wound solid corrugated tube is characterized in that it includes a corrugated tube body 3, which is a strip formed by winding and bonding a first profile 1 and a second profile 2 in a spiral direction. There is a corrugated pipe with continuously staggered wave crest structure 32 and wave trough structure 31. During the winding process of the first profile 1 in the spiral direction, the first splicing surface 1111 of the first half wave crest bar 111 is wound to the next circle and is exactly the same as the previous one. The second splicing surface 1121 in the second half wave crest strip 112 of the loop is spliced and bonded to each other to form the small wave crest structure 321 of the corrugated pipe body 3. The second profile 2 is just buckled and merged during the spiral winding process of the second profile 2 The large crest structure 322 of the corrugated tube body 3 is formed by bonding to the small crest structure 321. Th...

Embodiment 3

[0081] A method for manufacturing a hot-wound solid corrugated pipe is characterized in that the method includes the following steps:

[0082] ① Melt the materials of the support rib 11 and the gusset plate 21, and extrude the support rib 11 and the gusset plate 21 through two extruders;

[0083] ②The support rib 11 is penetrated into the inner cavity of the coating mold with the molten material of the hot coating layer for thermal coating, so that the outer wall of the support rib 11 is wrapped with the first hot coating layer 12, thereby making the second A profile 1; and the feeding device is activated while the hot coating is carried out to drive the supporting rib 11 to continuously enter the coating mold, wind on the outer wall of the inner sizing mold, and follow the operation of the inner sizing mold to make a spiral movement, making the phase The adjacent first half-wave crest strip 111 and the second half-wave crest strip 112 are spliced with each other and bonded toget...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com