An assembled bottle cap injection molding process

An assembled and bottle cap technology, which is applied to threaded products, household appliances, household components, etc., can solve the problem of inconvenient demoulding of bottle caps, and achieve the effects of easy demoulding, convenient production, and convenient twisting and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

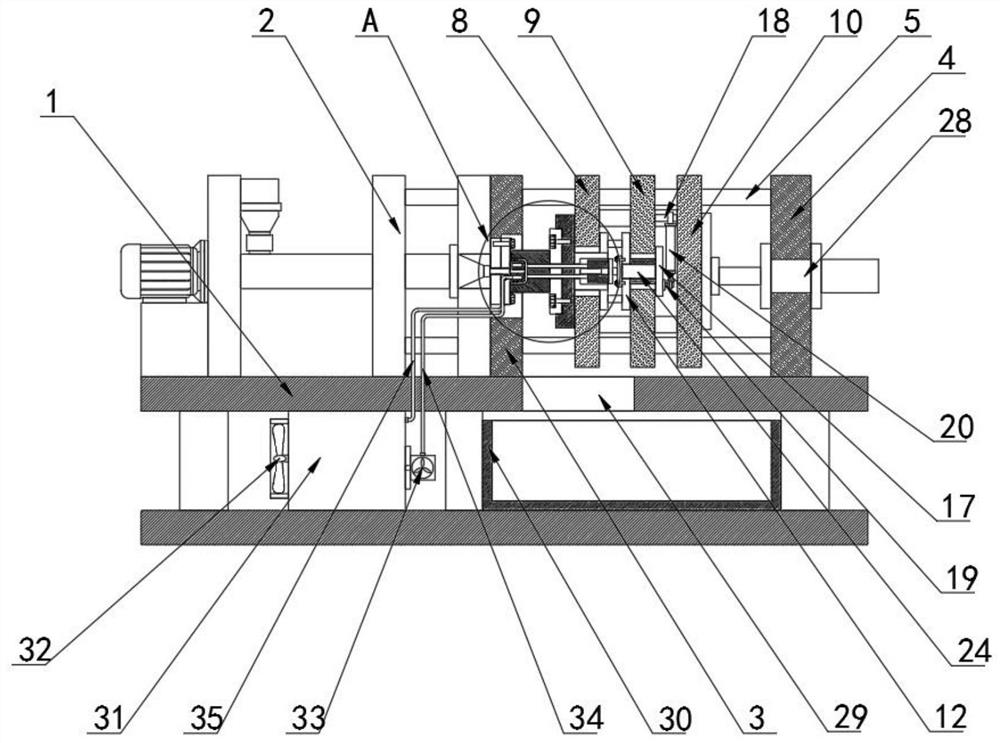

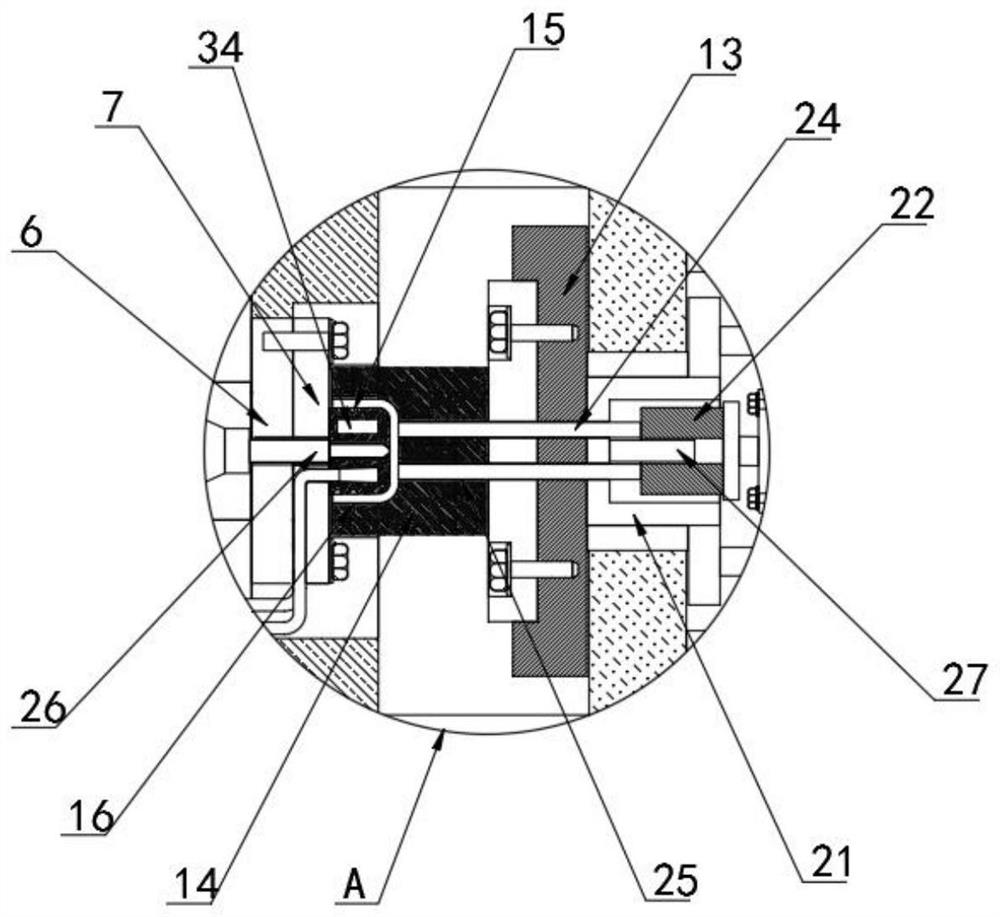

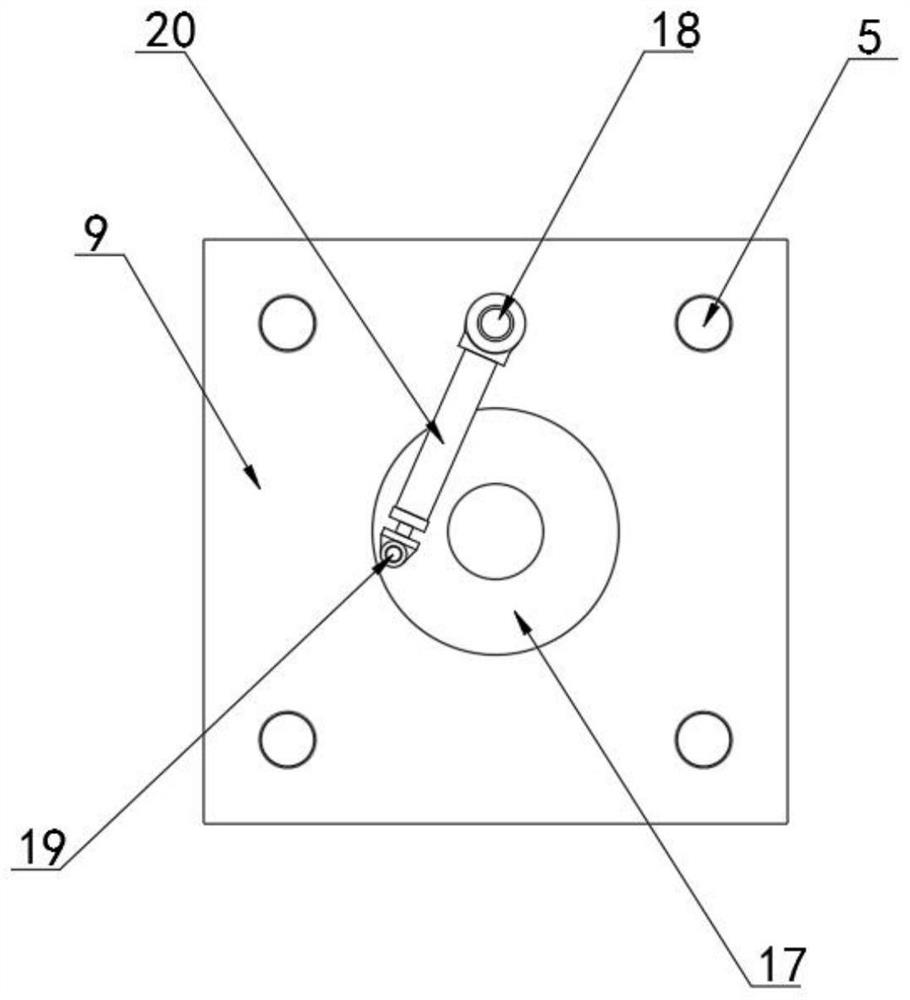

[0037] Refer to the attached Figure 1-7, an assembled bottle cap injection molding process in this embodiment, comprising a mold body 1, an injection molding frame 2 is fixedly arranged at one end of the top of the mold body 1, and a first fixed mold plate is fixedly arranged on one side of the injection molding frame 2 3. The other end of the top of the mold body 1 is fixedly provided with a second fixed mold plate 4, between the four corners of the first fixed mold plate 3 and the second fixed mold plate 4 there are fixed guide bars 5, the first The middle part of the fixed mold plate 3 is fixedly provided with a fixed mounting plate 6, the middle surface of the fixed mounting plate 6 is detachably provided with a bottle cap convex mold 7, and the surface of the guide slide bar 5 is sequentially provided with a first movable plate from left to right 8. The second movable plate 9 and the third movable plate 10, connecting columns 11 are fixed between the first movable plate ...

Embodiment 2

[0046] An injection molding process of an assembled bottle cap injection molding process, the specific operation steps are as follows:

[0047] Step 1: Select the corresponding bottle cap convex mold 7 and bottle cap concave mold 14, install the bottle cap convex mold 7 on the fixed mounting plate 6, and install the bottle cap concave mold 14 on the rotating mounting plate 13;

[0048] Step 2: Operate the mold opening and closing hydraulic cylinder 28 to push the third movable plate 10, drive the bottle cap convex mold 7 and the bottle cap concave mold 14 to perform mold clamping operation, and the subsequent injection molding equipment delivers the molten injection plastic to the bottle through the injection molding inlet pipe 26 In the injection molding space formed by the cap convex mold 7 and the bottle cap concave mold 14;

[0049] Step 3: The delivery pump 33 extracts the cooling water in the cooling water tank 31, and uses the water inlet pipe to transport it to the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com