Automatic temperature-rising power transmission line system

A technology of automatic heating and power transmission lines, applied in the direction of circuits, power cables, electrical components, etc., can solve the problems of wire galloping, damage to power transmission facilities, energy waste, etc., and achieve the effects of reducing volume, simplifying connections, and facilitating operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

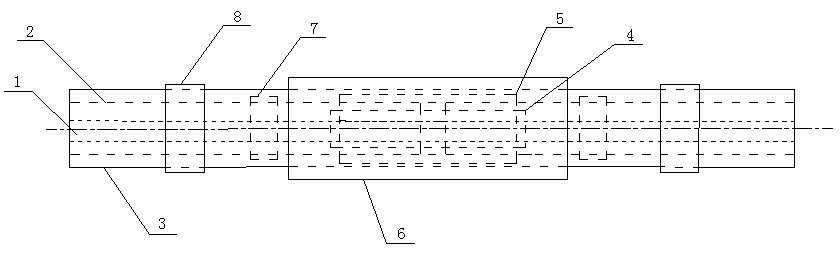

[0031] This embodiment includes a wire part, a heating part, and a ventilation part. The inside of the wire part is a cavity, and the cavity communicates with the ventilation part. The heating part is fixed on the wire part, and the heat generated by the heating part diffuses along the cavity through the ventilation part. To the entire transmission line, increase the temperature of the transmission line; two adjacent wire parts are connected by a wire splicing part to adapt to lines of different distances, and it is also easy to replace.

Embodiment 2

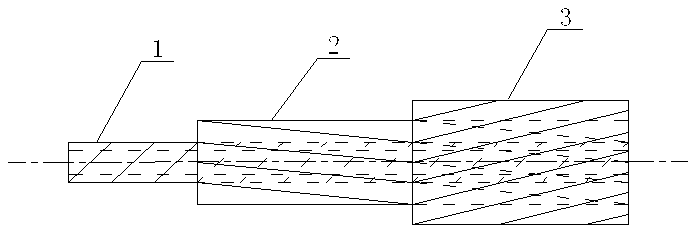

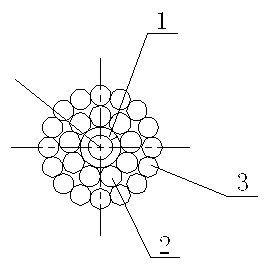

[0033] like figure 1 , figure 2 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the wire part is designed as a multi-layer structure, which includes a ventilation pipe 1, a traction layer 2 and a conductive layer 3 from the inside to the outside, and the traction layer 2 is composed of several Made of steel wire spirally wound on the ventilation pipe 1, the conductive layer 3 is made of several wires wound spirally on the traction layer 2, the ventilation pipe 1 ensures good ventilation, and the traction layer 2 ensures the transmission line Good support and traction, while the conductive layer 3 ensures the basic conductivity of the transmission line, so the wire part of the structure can ensure good ventilation, support, traction and conductivity.

[0034] As a preference, the ventilation pipe 1 of the present embodiment selects a steel spiral pipe, and the spiral direction of the steel spiral pipe is opposite to the spiral direction...

Embodiment 3

[0038] like Figure 3~8 As shown, this embodiment is basically the same as Embodiment 2. The difference is that this embodiment adopts a unique design for the heating part. The heating part includes a heating element 10 and two mutually symmetrical magnetic conductors 9. There are through holes 19, the upper ends of the two magnetic conductors 9 are hinged, and the middle parts of the two magnetic conductors 9 are respectively provided with a raised magnetic conductive strip 15, and the two magnetic conductive strips 15 are in contact with each other to form a closed structure with the two magnetic conductors 9. In the loop, the two magnetizers 9 are also provided with bayonet sockets 13, and the bayonet sockets 13 are located in the closed loop formed by the two magnetizer strips 15 and the two magnetizers 9. When working, the heating element 10 and the two magnetic conductors 9 are buckled on the wire part through the through hole 19 and the bayonet 13 respectively. Through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com