Automatic lifting rainwater well lid

A technology for water wells and manhole covers, which is applied in water conservancy projects, underwater structures, buildings, etc., and can solve problems such as small force and cylinder damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

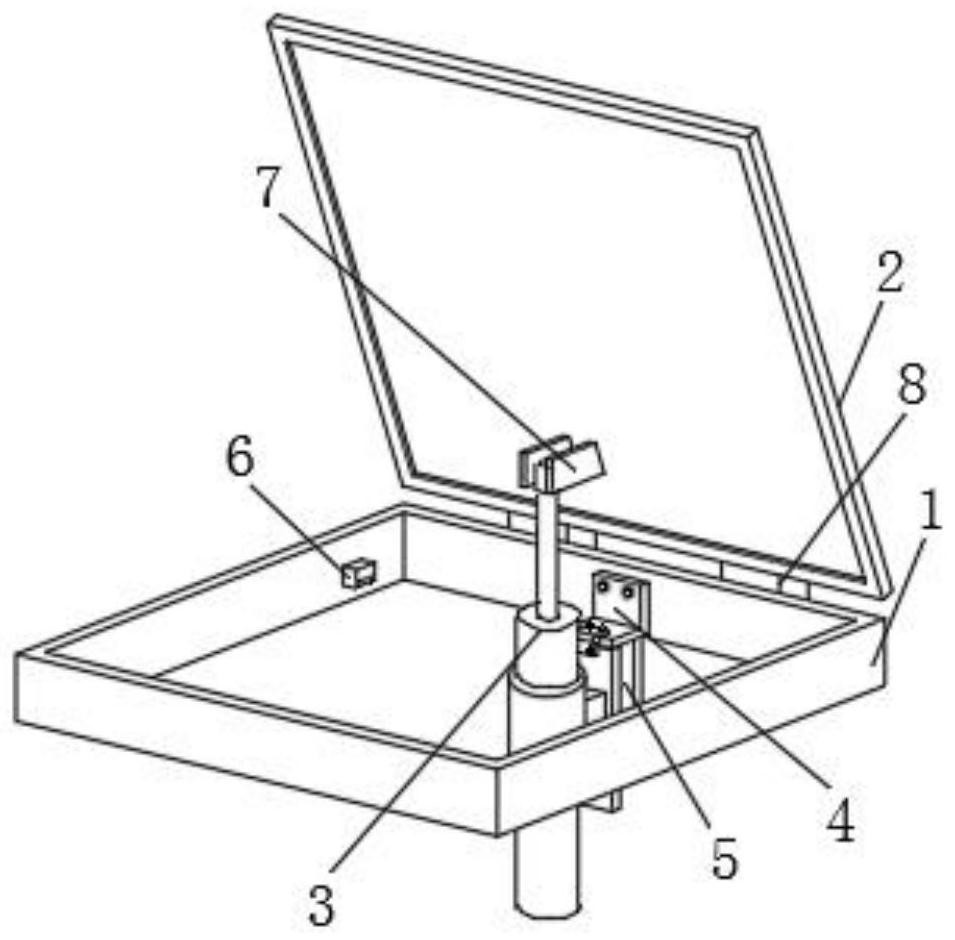

[0028] This embodiment provides a specific structure of an automatic lifting rainwater manhole cover, such as Figure 1-5 As shown, it includes: a jacking mechanism and a protective mechanism, the jacking mechanism is used to open and close the manhole cover; the protective mechanism is detachably installed above the jacking mechanism for protection;

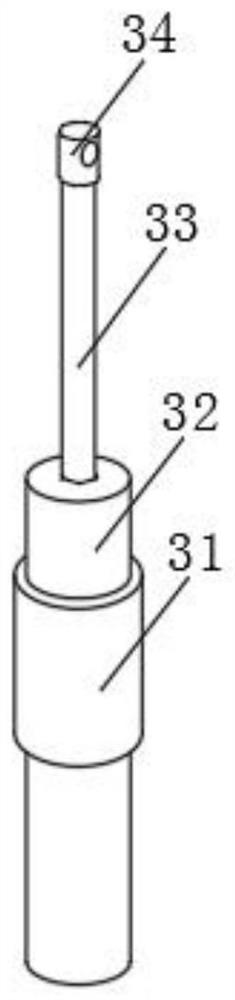

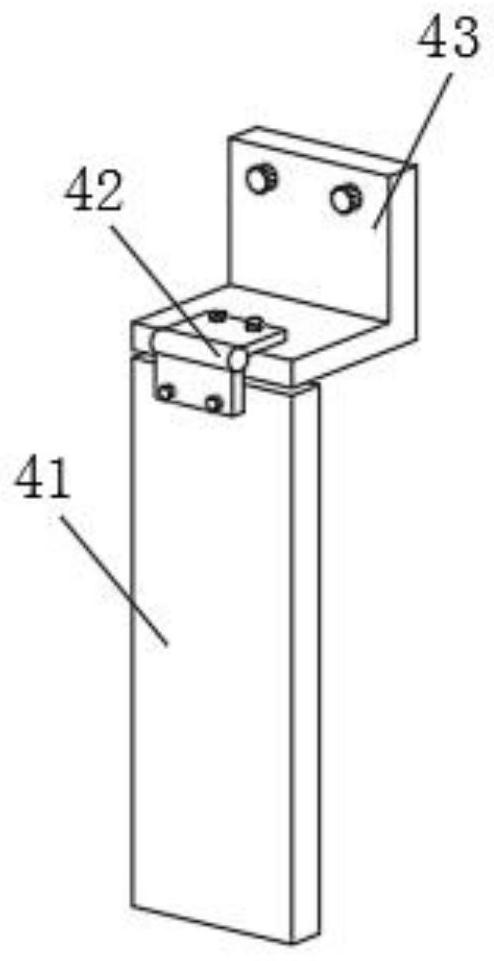

[0029] The jacking mechanism includes a cylinder assembly 3, one side of the cylinder assembly 3 is provided with a connecting assembly 4, the other side of the connecting assembly 4 is provided with a horizontal transmission assembly 5, and the connecting assembly 4 includes a vertical plate 41 and a fixing plate 43. The plate 41 is arranged below the fixing plate 43, and the connecting assembly 4 also includes a connecting piece 42, and the connecting piece 42 is installed at the intersection of the vertical plate 41 and the fixing plate 43. When the horizontal transmission assembly 5 runs, it pushes the connecting assembly 4 t...

Embodiment 2

[0034] This embodiment provides a specific structure of an automatic lifting rainwater manhole cover, such as Figure 1-5 As shown in the figure, the present embodiment also describes a protection mechanism, which is detachably installed above the jacking mechanism for protection. The protection mechanism includes a manhole cover main body 2; a frame 1, which is detachably installed on the The lower part of the manhole cover main body 2 is used to fix the whole manhole cover, and also includes a control assembly 6, which is detachably installed on the inner side of the frame 1 and used to control the operation of the jacking mechanism.

[0035] The control assembly 6 includes a waterproof cover 64, and a casing 62 is arranged inside the waterproof cover 64. A start button 61 is provided at the axis of the surface wall of the casing 62, and two ends of the start button 61 are provided with a fluorescent plate 63. A waterproof cover 64 is provided on the outside for protection, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com