Low-thermal-conductivity refractory material, low-thermal-conductivity refractory brick, preparation method of refractory brick and application

A refractory material and low thermal conductivity technology, applied in the field of refractory materials, can solve the problems of heat loss, energy waste, large thermal conductivity of magnesia-chrome bricks, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028]In the present invention, the raw materials for the preparation of the low thermal conductivity refractory material include light spinel particles. In the present invention, the preparation method of the light spinel particles preferably includes the following steps:

[0029] Grinding and mixing alumina, magnesite, pore-forming agent, binder and water to obtain mixed mud;

[0030] The mixed mud is dehydrated and sintered in sequence to obtain light spinel particles.

[0031] The invention grinds and mixes alumina, magnesite, pore-forming agent, binder and water to obtain mixed mud. In the present invention, the alumina is preferably gamma-industrial alumina, the pore-forming agent is preferably PMMA microspheres (Beijing Senchang Taihe Co.), plant powder or activated carbon, and the binding agent is preferably lignin sulfonate salt or carboxymethylcellulose. In the present invention, the mass ratio of alumina, magnesite, pore-forming agent, binder and water is prefera...

Embodiment 1

[0051] The preparation of lightweight spinel particles comprises the following steps:

[0052] In terms of parts by mass, 55 parts of alumina (specifically γ-industrial alumina), 45 parts of magnesite, 1 part of pore-forming agent (specifically PMMA material microspheres, purchased from Beijing Senchang Taihe Company), 0.5 Part binding agent (being specifically carboxymethyl cellulose) is ground and mixed with 130 parts of water, obtains mixed sludge;

[0053] The mixed mud is pumped into a filter press for dehydration, and then the mud is refined by a vacuum mud mill, extruded and cut to form a mud section, and then dried, sintered and crushed in sequence to obtain light spinel particles; , the pressure of the dehydration is 2.3MPa; the vacuum degree of the vacuum mud mill is 0.085MPa; the mud section formed after extrusion cutting is cylindrical with a diameter of 20mm and a length of 50mm; the drying temperature is 270°C, The time is 2 hours, the residual moisture content ...

Embodiment 2~4

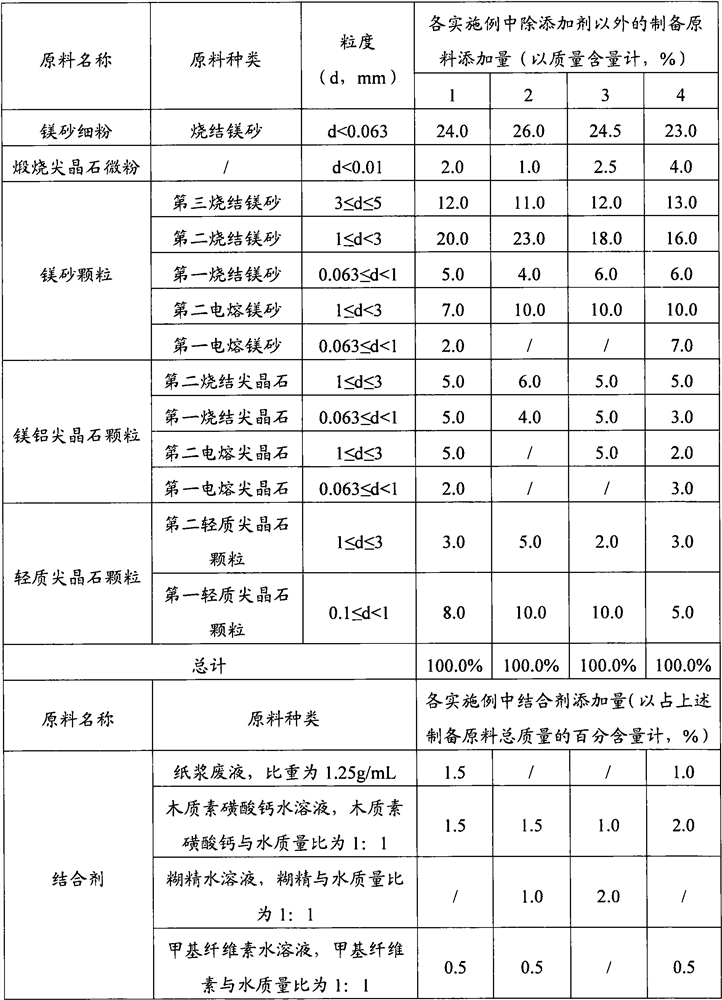

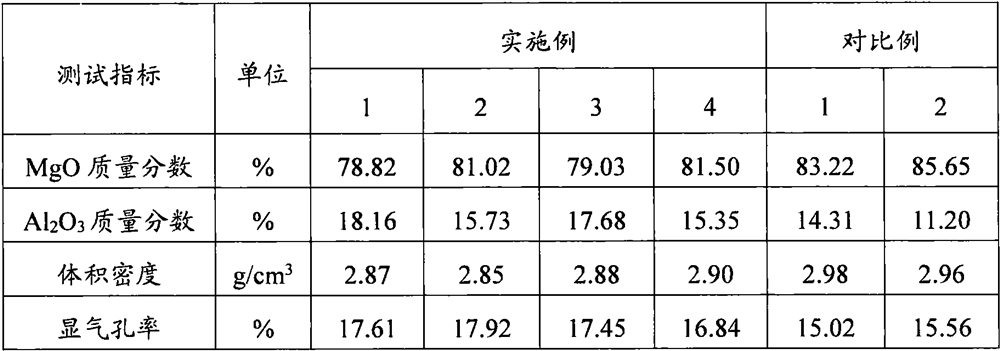

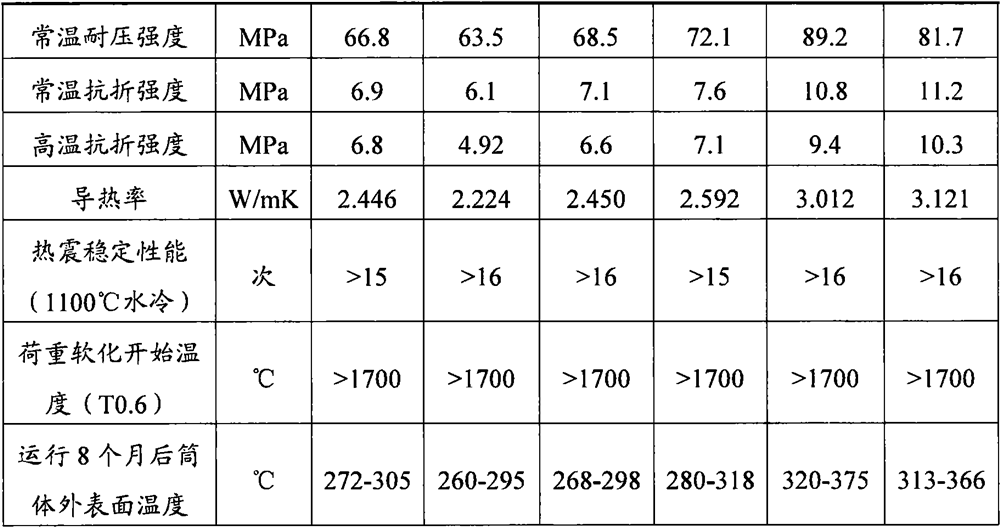

[0063] The low thermal conductivity refractory bricks were prepared according to the method of Example 1. The raw materials and addition amounts of the low thermal conductivity refractory materials in each embodiment are shown in Table 1.

[0064] In Table 1, the total amount of magnesia particles, magnesia fine powder, magnesia-aluminum spinel particles, light spinel particles and calcined spinel micropowder is calculated in 100%, and the quality of the binding agent is represented by magnesia particles, The percentage content of the total mass of magnesia fine powder, magnesium aluminum spinel particles, light spinel particles and calcined spinel powder.

[0065] Table 1 Raw materials and addition amount used in the preparation of low thermal conductivity refractory materials in Examples 1-4

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com