High-flexibility copper-clad steel wire

A copper-clad steel wire, high flexibility technology, applied in the field of high-flexibility copper-clad steel wire, can solve the problems of poor fatigue resistance, low flexibility, easy to break, etc., achieve strong deformation resistance, improve flexibility, increase The effect of large fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

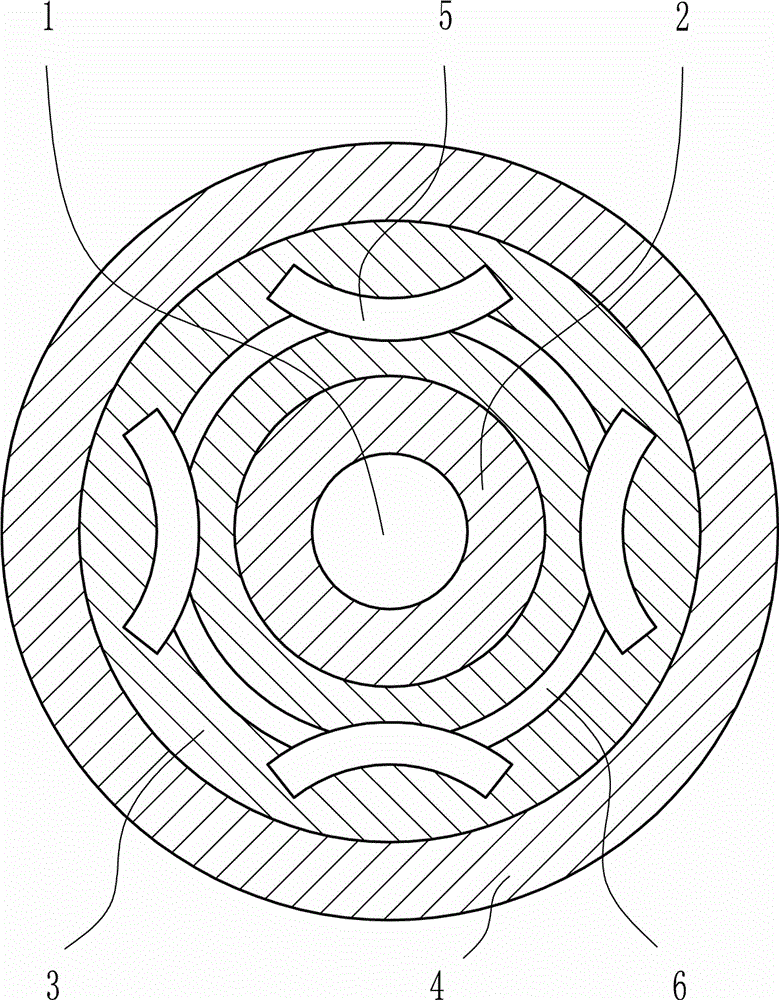

[0030] A highly flexible copper-clad steel wire such as figure 1 As shown, it includes a low-carbon steel layer 2, a pure iron layer 3, a copper-plated layer 4, an arc-shaped outer curved sheet 5, and an arc-shaped inner curved sheet 6; The carbon steel layer 2 wraps the hollow layer 1 ; the low carbon steel layer 2 is provided with a pure iron layer 3 outside, and the pure iron layer 3 wraps the low carbon steel layer 2 .

[0031] The interior of the pure iron layer 3 is provided with 4 arc-shaped outer bending sheets 5, and the 4 arc-shaped outer bending sheets 5 are evenly arranged in the interior of the pure iron layer 3 along the circumferential direction, and the 4 arc-shaped outer bending sheets 5 are all 304. Stainless steel; the outside of the pure iron layer 3 is provided with a copper plating layer 4 , and the copper plating layer 4 wraps the pure iron layer 3 .

[0032] Working principle: A hollow layer 1 is arranged inside the low carbon steel layer 2. It is prov...

Embodiment 2

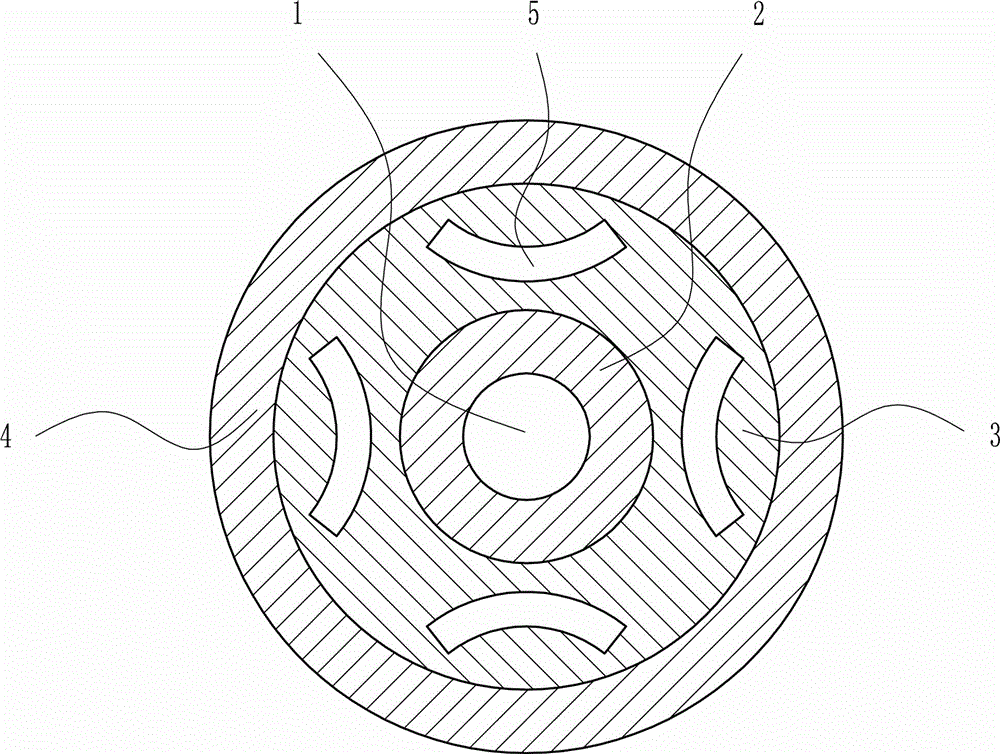

[0035] A highly flexible copper-clad steel wire such as figure 1 As shown, it includes a low-carbon steel layer 2, a pure iron layer 3, a copper-plated layer 4, an arc-shaped outer curved sheet 5, and an arc-shaped inner curved sheet 6; The carbon steel layer 2 wraps the hollow layer 1 ; the low carbon steel layer 2 is provided with a pure iron layer 3 outside, and the pure iron layer 3 wraps the low carbon steel layer 2 .

[0036] The interior of the pure iron layer 3 is provided with 4 arc-shaped outer bending sheets 5, and the 4 arc-shaped outer bending sheets 5 are evenly arranged in the interior of the pure iron layer 3 along the circumferential direction, and the 4 arc-shaped outer bending sheets 5 are all 304. Stainless steel; the outside of the pure iron layer 3 is provided with a copper plating layer 4 , and the copper plating layer 4 wraps the pure iron layer 3 .

[0037] like figure 2 As shown, it also includes 4 arc-shaped inner-bending sheets 6; 4 arc-shaped in...

Embodiment 3

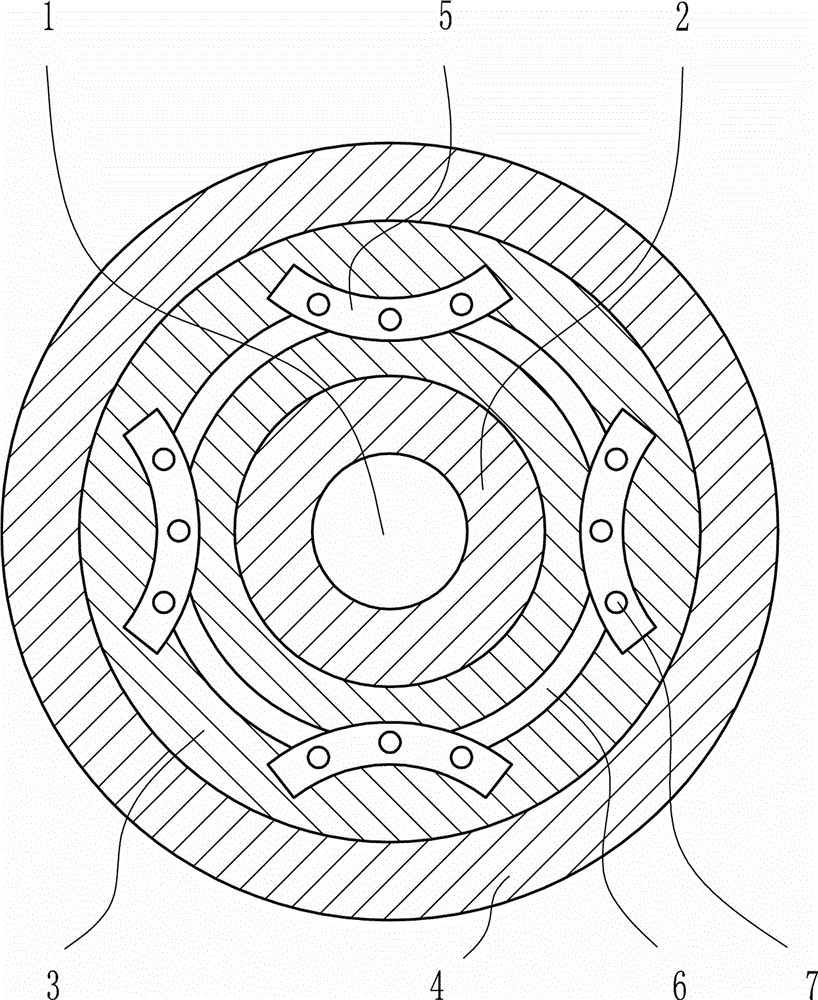

[0042] A highly flexible copper-clad steel wire such as figure 1 As shown, it includes a low-carbon steel layer 2, a pure iron layer 3, a copper-plated layer 4, an arc-shaped outer curved sheet 5, and an arc-shaped inner curved sheet 6; The carbon steel layer 2 wraps the hollow layer 1 ; the low carbon steel layer 2 is provided with a pure iron layer 3 outside, and the pure iron layer 3 wraps the low carbon steel layer 2 .

[0043] The interior of the pure iron layer 3 is provided with 4 arc-shaped outer bending sheets 5, and the 4 arc-shaped outer bending sheets 5 are evenly arranged in the interior of the pure iron layer 3 along the circumferential direction, and the 4 arc-shaped outer bending sheets 5 are all 304. Stainless steel; the outside of the pure iron layer 3 is provided with a copper plating layer 4 , and the copper plating layer 4 wraps the pure iron layer 3 . Also includes 4 arc-shaped inner-bending sheets 6; 4 arc-shaped inner-bending sheets 6 are evenly arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com