Chemical vapor deposition reactor or epitaxial layer growth reactor and support device thereof

A chemical vapor deposition and supporting device technology, which is applied in directions from chemically reactive gases, chemical instruments and methods, crystal growth, etc., can solve the problem of cracking of the substrate carrier 300, inability to accurately measure the substrate temperature, and inability to accurately measure the reaction In-device substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

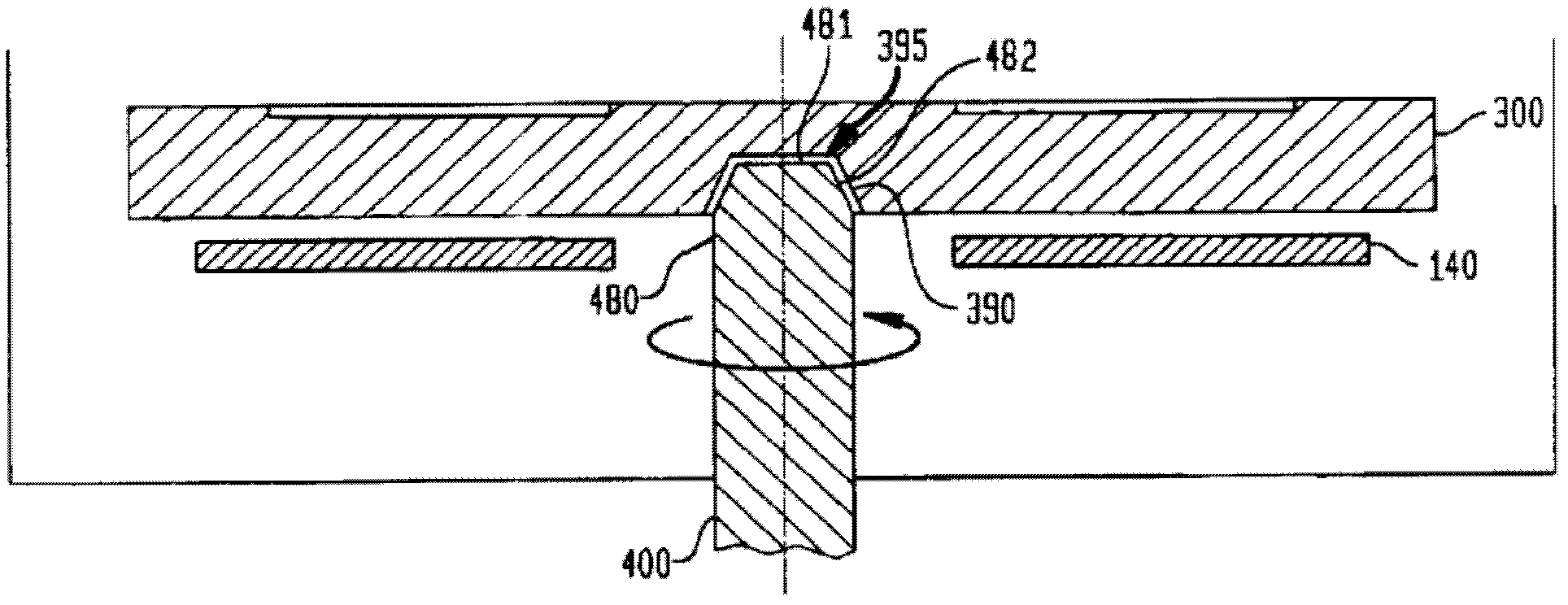

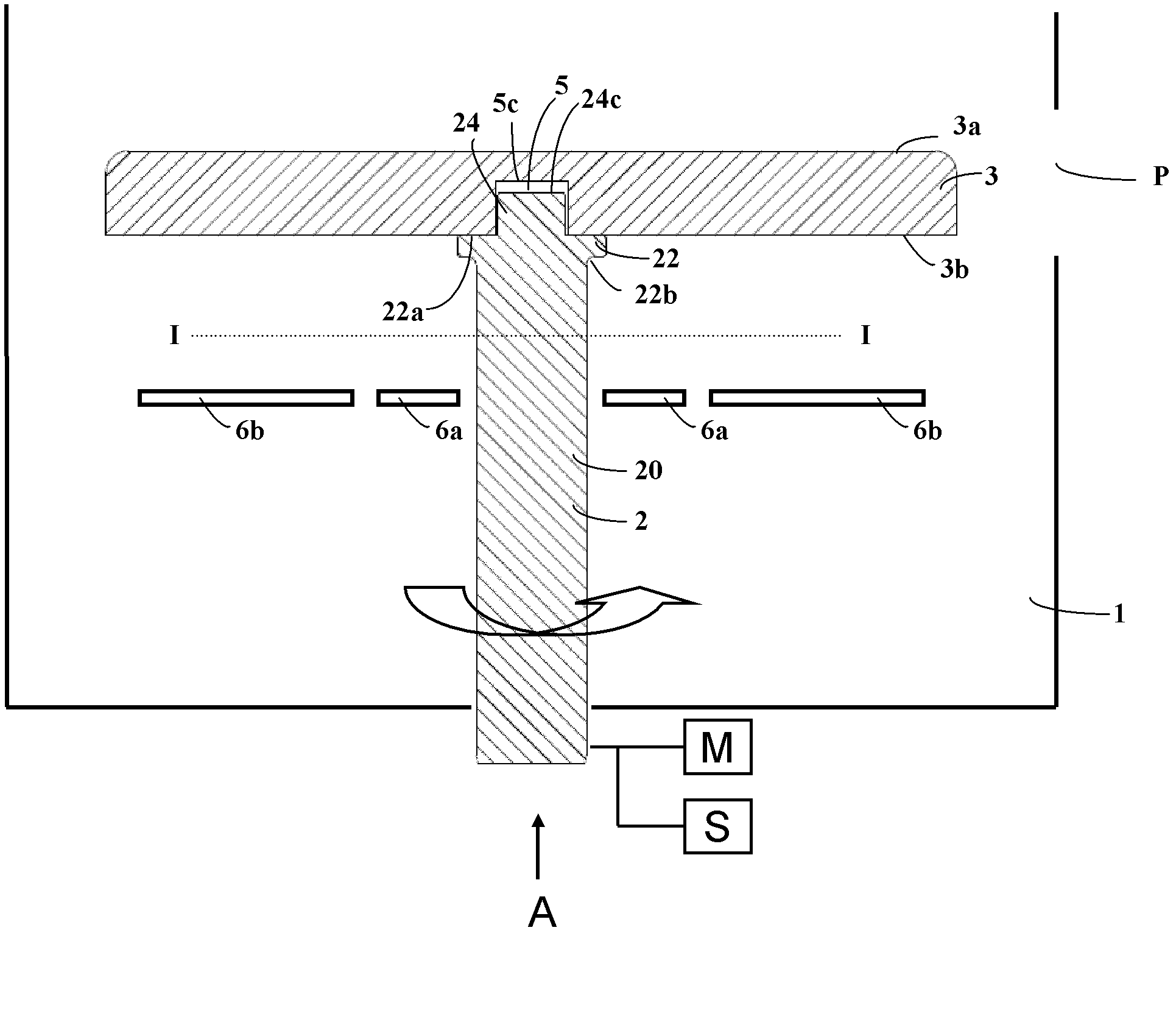

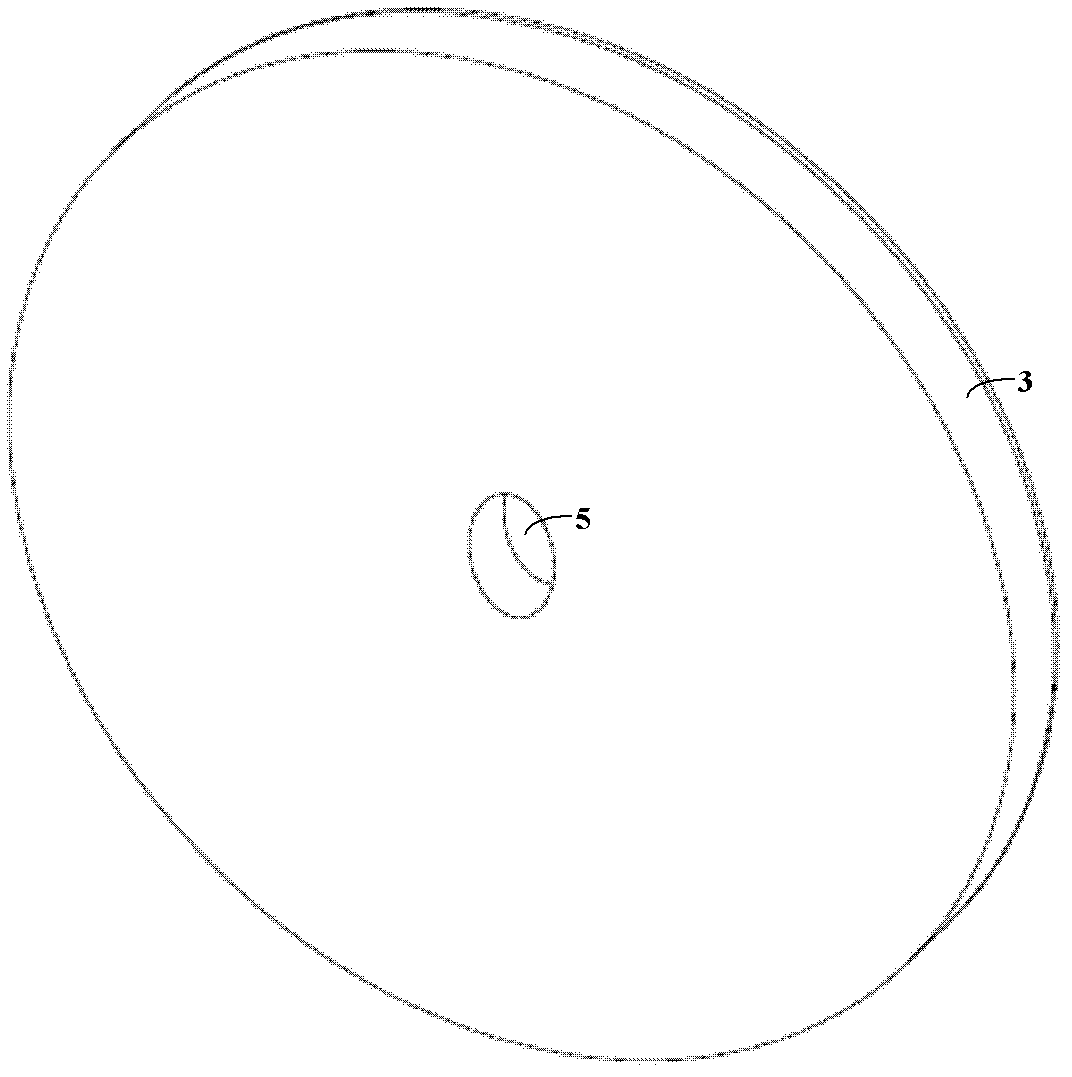

[0042] like Figure 2A as shown, Figure 2A A front view cross-sectional schematic view of a reactor provided according to an embodiment of the present invention is shown. The reactor may be used for chemical vapor deposition or epitaxial layer growth, but it should be understood that it is not limited to such applications. The reactor includes a reaction chamber 1, and at least one substrate carrier 3 and a supporting device 2 for supporting the substrate carrier 3 are arranged in the reaction chamber 1. The side wall of the reaction chamber 1 is provided with a transport port P for transporting the substrate carrier 3 in and out. The substrate carrier 3 includes a first surface 3a and a second surface 3b, wherein the first surface 3a is used to place a number of processed substrates, preferably, the first surface 3a is provided with some 20 substrates for placing Grooves or dimples (not shown) of the processed substrate (not shown). The second surface 3b of the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com