Method for preparing thick film of superfine crystal in pure aluminum through DC magnetism controlled sputtering

A DC magnetron sputtering, ultra-fine grain technology, used in sputtering, ion implantation, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

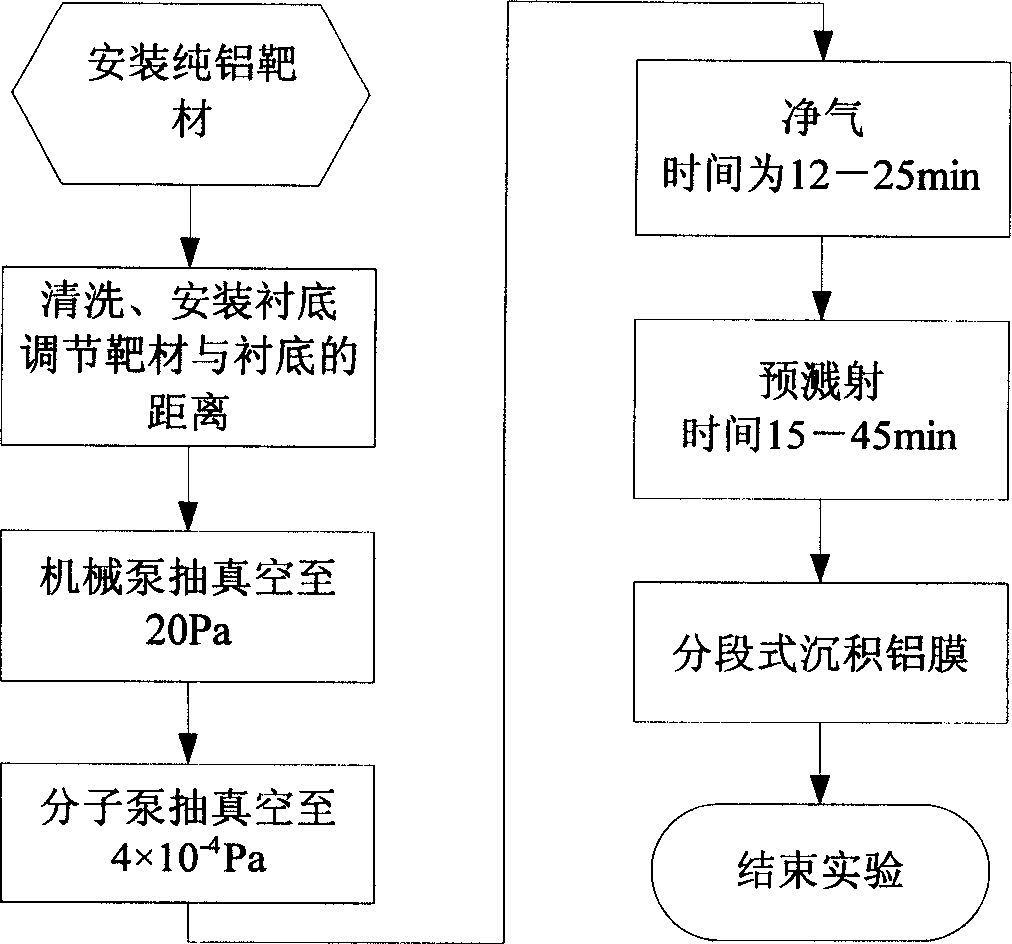

Method used

Image

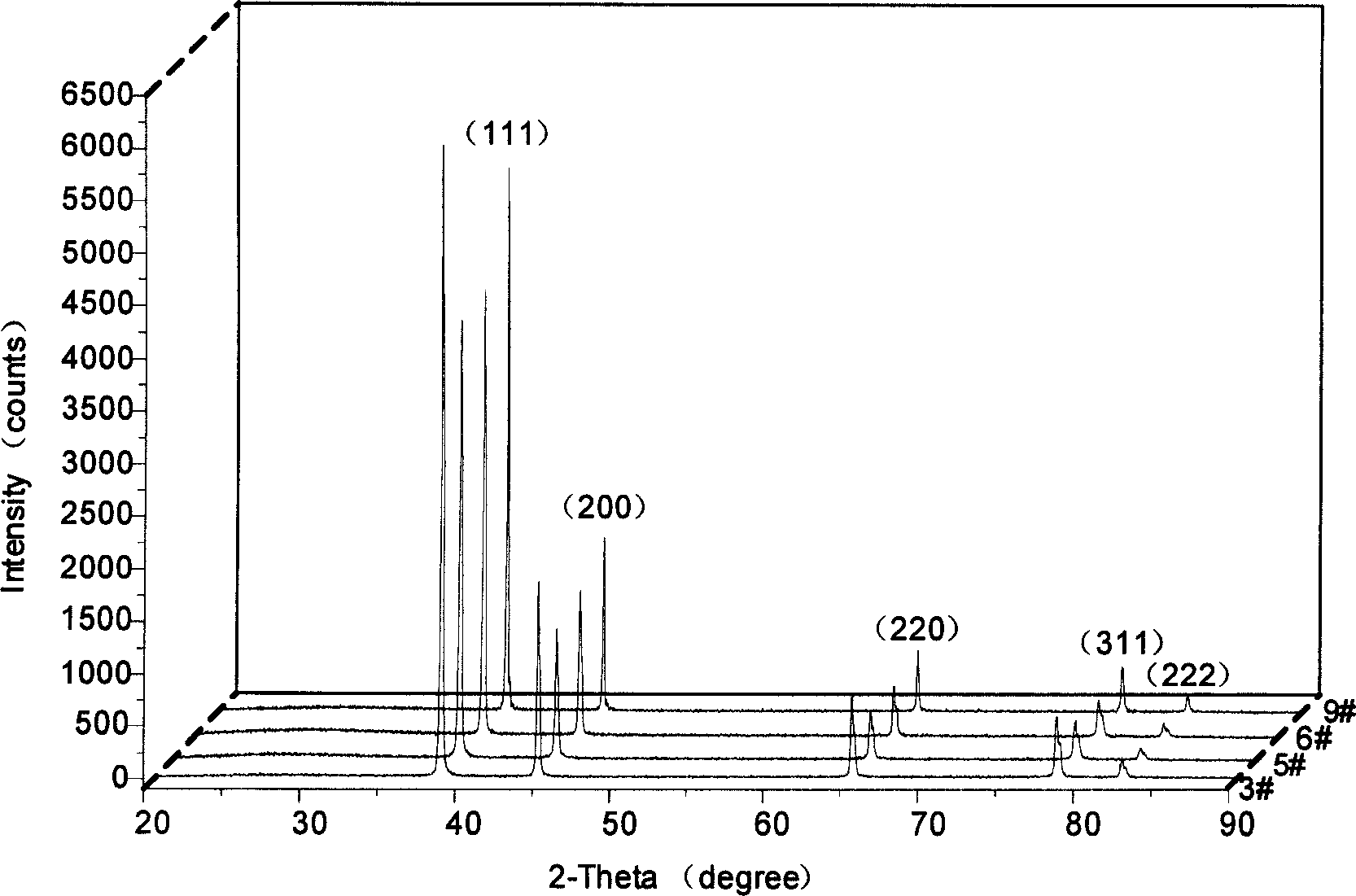

Examples

Embodiment 1

[0035] Example 1: Preparation of pure aluminum ultra-fine grain thick film on K glass substrate

[0036] The universal ultra-high vacuum DC magnetron sputtering equipment is used, and a pure aluminum target with a purity of 99.999% is installed on the target stage.

[0037] Choose K glass as the substrate, clean and dry the substrate substrate, then clamp the substrate with a sample holder, and put it into a vacuum chamber. The distance between the target and the substrate is 60mm.

[0038] Use a mechanical pump to evacuate to about 20Pa, and then use a molecular pump to evacuate. The background is generally required to be higher than 10 -4 Therefore, it is necessary to ensure that the vacuuming time is greater than 40 minutes, so that the background vacuum degree is 4×10 -4 Pa;

[0039] Introduce high-purity argon, adjust the flow rate to 20cm 3 / s, keep the vacuum system for 15 minutes of purging.

[0040] After the vacuum degree is stable, start pre-sputtering for 15 mi...

Embodiment 2

[0044] Embodiment 2: Si substrate substrate pure aluminum ultra-fine grain thick film preparation

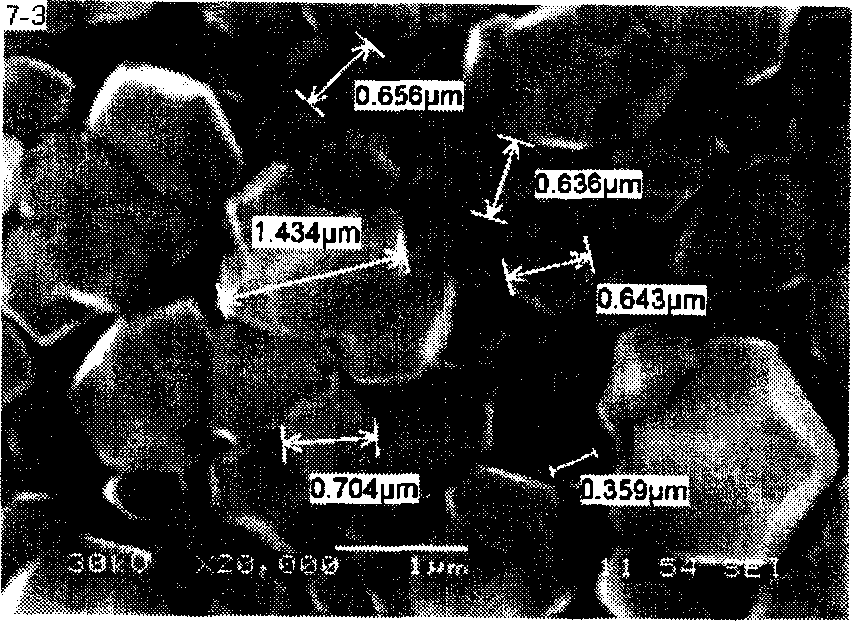

[0045] The preparation method is the same as in Example 1, the substrate is replaced with a polished Si substrate, and the process parameters are the same as in Example 1. The prepared pure aluminum ultra-fine grain thick film has a film thickness of more than 2 μm, low surface roughness, and good film ratio and orientation. Figure 3b That is to say, it shows the surface morphology of the pure aluminum film on Si as the substrate, and its grains are finer.

Embodiment 3

[0046] Example 3: Preparation of pure aluminum ultra-fine grain thick film deposited on the surface of AZ31B magnesium alloy

[0047] Deposit one layer of pure aluminum ultra-fine grain thick film on the surface of AZ31B magnesium alloy, the preparation method is the same as that of Example 1, and the process parameters are: the flow rate of argon gas is 30cm 3 / s, the air purification time is 10min. The pre-sputtering time is 20min, the current is 0.8A, and the voltage is 300V; during deposition, the working pressure is 1.0Pa, the sputtering current is 1.4A, and the sputtering voltage is 250V; the deposition is carried out in stages until a certain thickness of pure aluminum with fine grains is obtained Ultra-fine grain thick film, the film thickness is above 2μm. . Figure 5 shows the polarization curves of AZ31B magnesium alloy before and after depositing pure aluminum ultrafine grain thick film.

[0048] It is found by electrochemical test that the corrosion potential of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com