MOF (metal-organic framework) separating layer film and preparation method thereof

A metal-organic framework and separation layer technology, applied in the field of ion exchange membranes, can solve the problems of reduced ion flux, reduced strength, difficult control of the thickness of the MOF layer, etc., and achieves improved separation coefficient, improved flux, and a simple and controllable preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

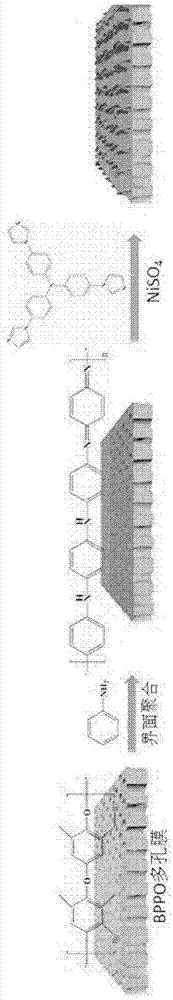

[0034] Therefore, the present invention proposes a method for preparing a metal-organic framework separation layer membrane, comprising the following steps:

[0035] Step 1, forming a surface modification layer on the surface of the base film by interfacial polymerization;

[0036] Step 2. Secondary growth on the surface modification layer to form a metal-organic framework separation layer to complete the preparation of the metal-organic framework separation layer membrane.

[0037] Specifically, the present invention provides a method for preparing a two-dimensional oriented metal-organic framework separation layer film (MOF separation layer film), comprising the following steps:

[0038] Step S1, forming a surface modification layer on the surface of the base film through interfacial polymerization;

[0039] Step S2, secondary growth on the surface modification layer obtained in step S1 to form a MOF separation layer to obtain a MOF separation layer film.

[0040] The pres...

Embodiment 1

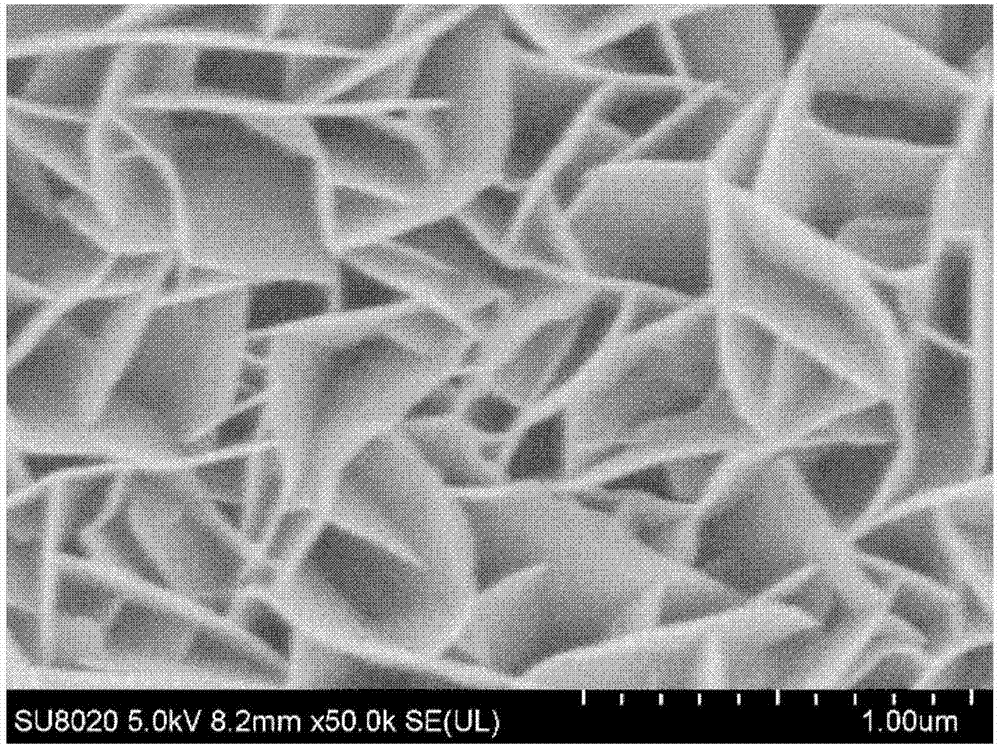

[0062] This embodiment proposes a method for preparing a MOF separation layer membrane, the preparation process is as follows figure 1 As shown, specifically:

[0063] 1.1. Preparation of base film

[0064] A certain mass of brominated polyphenylene ether (bromination degree 30% to 70%) was dissolved in methylpyrrolidone to obtain a uniform film solution with a mass fraction of 20%, and the film solution was uniformly coated on a glass plate, and the film was removed with a spatula. Control the thickness of the membrane liquid; after uniform coating, immediately immerse the glass plate in water, soak for 24 hours, then take out to obtain the base film, which is a porous film with finger-shaped holes in this embodiment.

[0065] 1.2. Interfacial polymerization reaction of basement film

[0066] 1.2.1. Dissolve aniline with HCl solution with a concentration of 0.1-0.2mol / L, and prepare aniline hydrochloric acid solution with a concentration of 0.1-0.15mol / L, and the solution i...

Embodiment 2

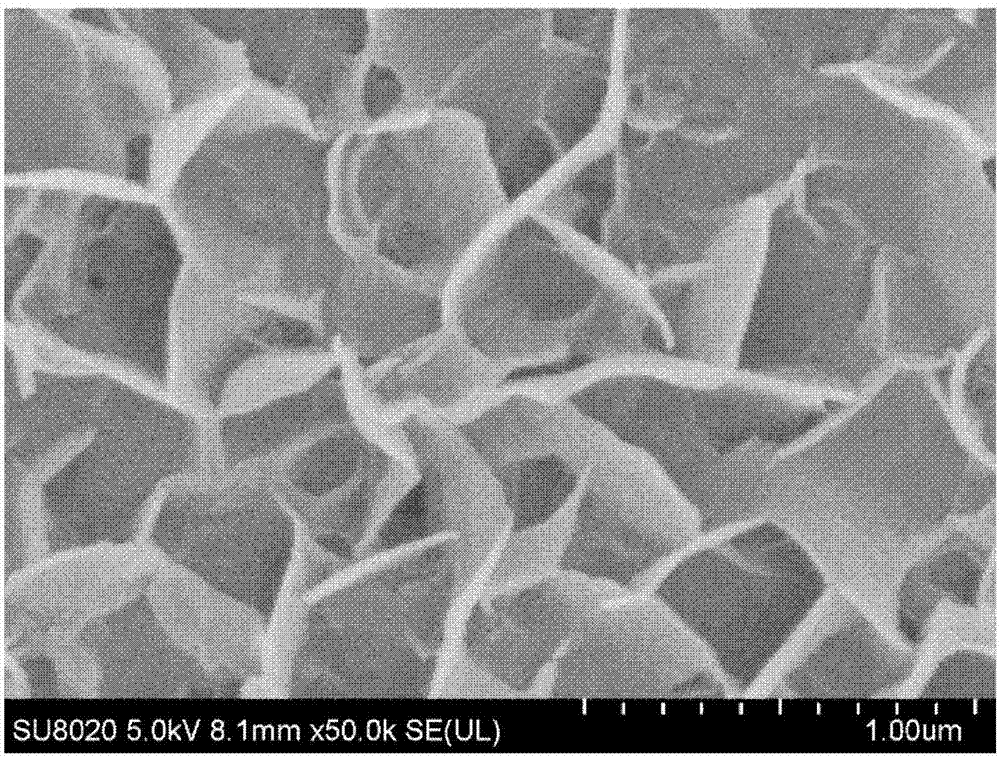

[0075] This embodiment proposes a kind of preparation method of MOF separation layer membrane, and this method is specifically similar to embodiment 1, and difference is only, the modified membrane that obtains is put into and filled with 30ml (containing 8mmol cobalt sulfate and 5mmol 1-methylimidazole ) N, N-dimethylformamide and water mixed liquid polytetrafluoroethylene reactor, wherein, N, N-dimethylformamide and water volume ratio is 1:1, at 100 ℃ temperature , after reacting for 20 hours, take out the modified membrane and let it stand in the air for 1.5 hours; then put it into a polytetrafluoroethylene reactor filled with the mixed solution, react at 70°C for 26 hours, take out the membrane and rinse it with water, that is A MOF separation layer membrane can be obtained. That is, the two-dimensional orientation type MOF separation layer is formed on the surface modification layer of the base film through secondary heating reaction, and the MOF separation layer film is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com