Magnesium radical differential arc oxidization electrolytic solution and its differential arc oxidation process

A magnesium-based micro-arc and micro-arc oxidation technology, applied in anodizing and other directions, can solve the problems of reduced breakdown voltage, environmental and personal health hazards, poor corrosion resistance, etc., and achieves the effect of smooth surface, easy control and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In deionized water, first add 2g / L oxalic acid C 2 h 2 o 4 .2H 2 O and 6 g / L sodium acetate CH 3 COONa, stir well to dissolve completely, pH value is 5, finally add 14g / L potassium fluozirconate K 2 ZrF6.

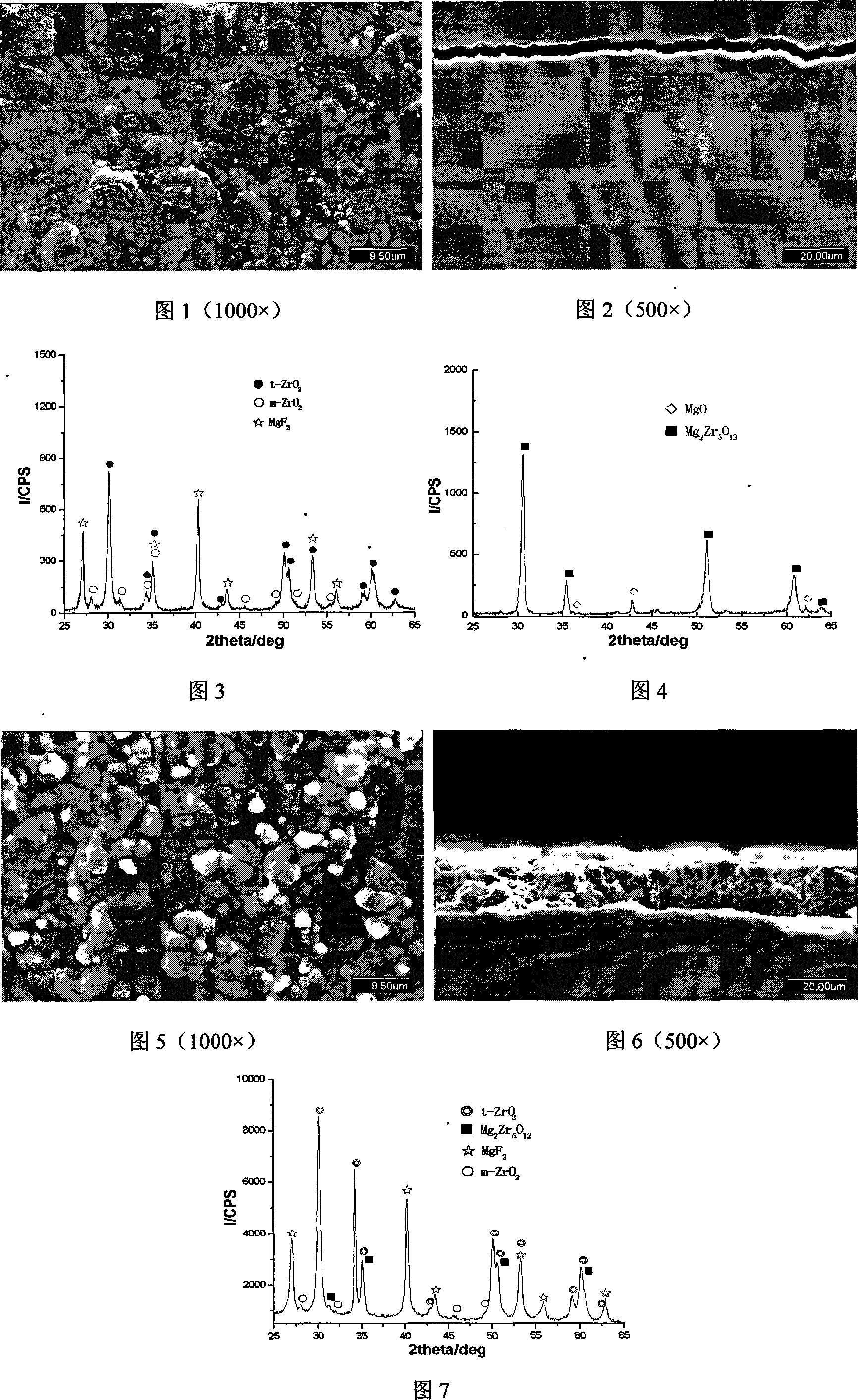

[0031] Using pure magnesium as the anode and stainless steel as the cathode, in the above prepared electrolyte, using a pulse power supply, under the conditions of a constant voltage of 550V, a frequency of 100Hz, a duty ratio of 26%, and a distance between the cathode and anode plates of 10cm. After arc oxidation treatment for 20 minutes, apply 550V within 30s, and maintain the temperature of the electrolyte at 20°C, a film with a thickness of 60μm and a surface hardness of 403Hv can be prepared. The microscopic morphology of the surface and cross-section of the film layer are shown in Figure 1 and Figure 2, respectively. The phase composition is shown in Figure 3.

Embodiment 2

[0033] In deionized water, first add 3g / L oxalic acid C 2 h 2 o 4 .2H 2 O and 8 g / L sodium acetate CH 3 COONa, fully stirred and dissolved completely, the pH value is 4.5, finally add 17g / L potassium fluozirconate K 2 ZrF 6 .

[0034] Using MB8 magnesium alloy as the anode and stainless steel as the cathode, in the above prepared electrolyte, using a pulse power supply, under the conditions of a constant voltage of 500V, a frequency of 100Hz, a duty cycle of 26%, and a distance between the cathode and anode plates of 9cm Perform micro-arc oxidation treatment for 60 minutes, apply 500V within 30s, and maintain the temperature of the electrolyte at 18°C to obtain a film with a thickness of 130μm.

Embodiment 3

[0036] In deionized water, first add 10g / L oxalic acid C 2 h 2 o 4 .2H 2 O and 20g / L sodium acetate CH 3 COONa, stir well to dissolve completely, pH value is 5, finally add 3g / L potassium fluozirconate K 2 ZrF 6 .

[0037] Using pure magnesium as the anode and stainless steel as the cathode, in the above-mentioned prepared electrolyte, using a pulse power supply, under the conditions of a constant voltage of 650V, a frequency of 2000Hz, a duty ratio of 40%, and a distance between the cathode and anode plates of 12cm. Arc oxidation treatment was performed for 90min, and the temperature was increased to 650V within 40s, maintaining the temperature of the electrolyte at 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com