Patents

Literature

36results about How to "Does not contain easily decomposable ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

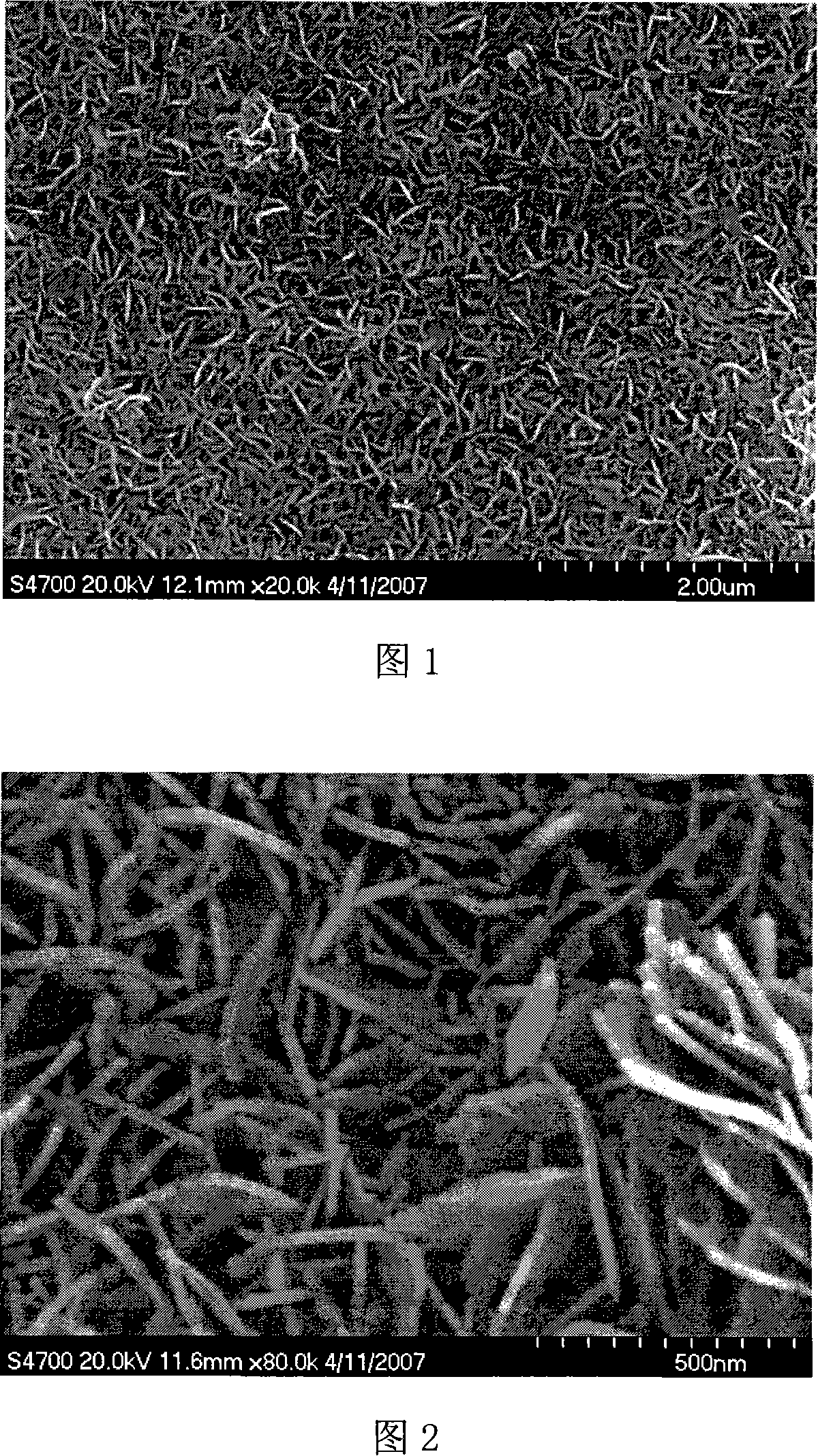

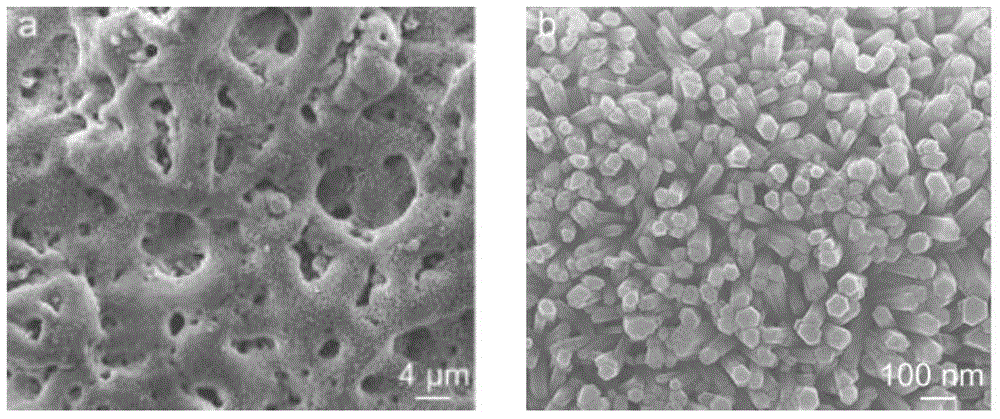

Process for preparing compact magnesium oxide/hydroxyapatite nano fiber double-layer coating on surface of magnesium base

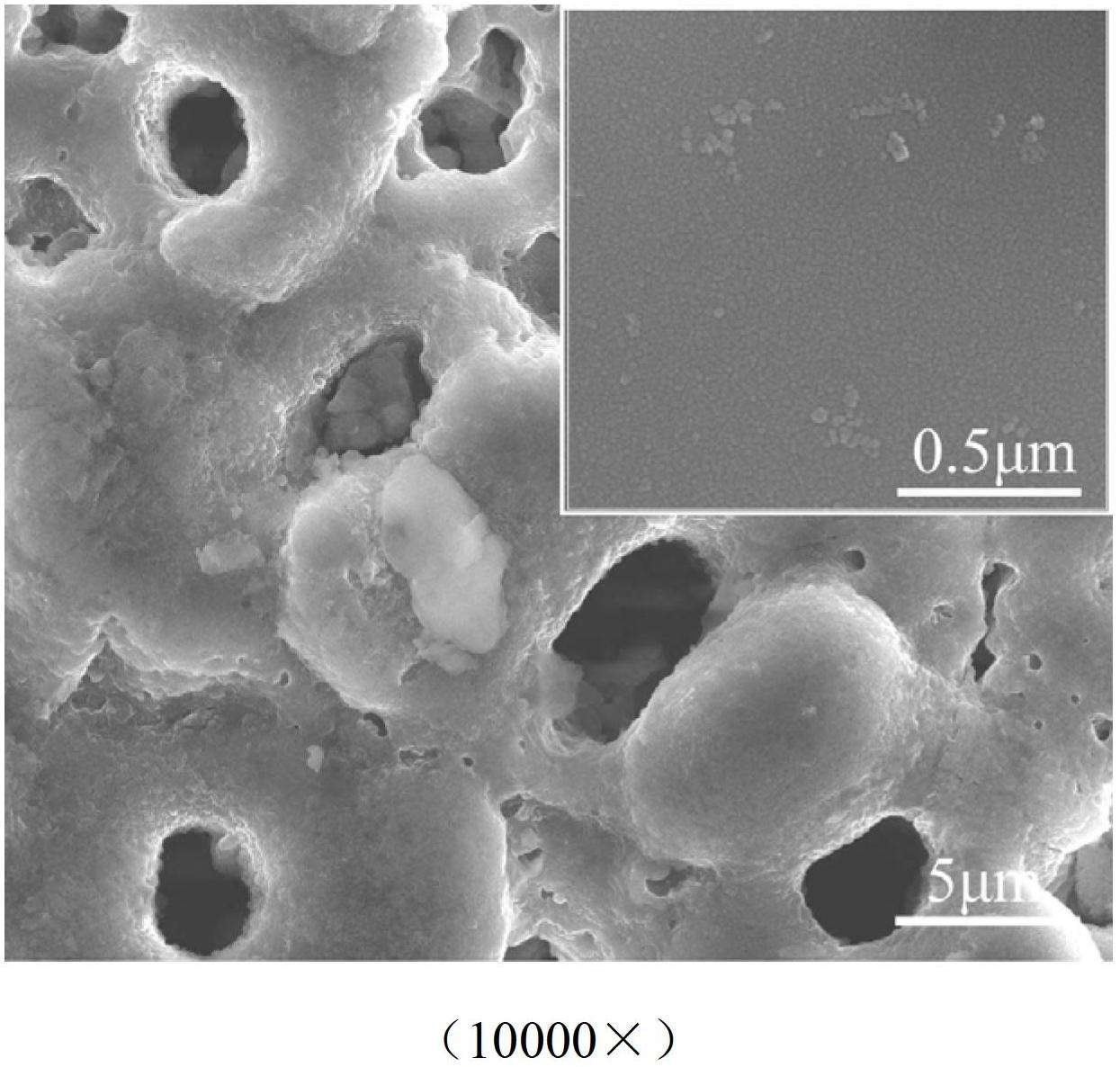

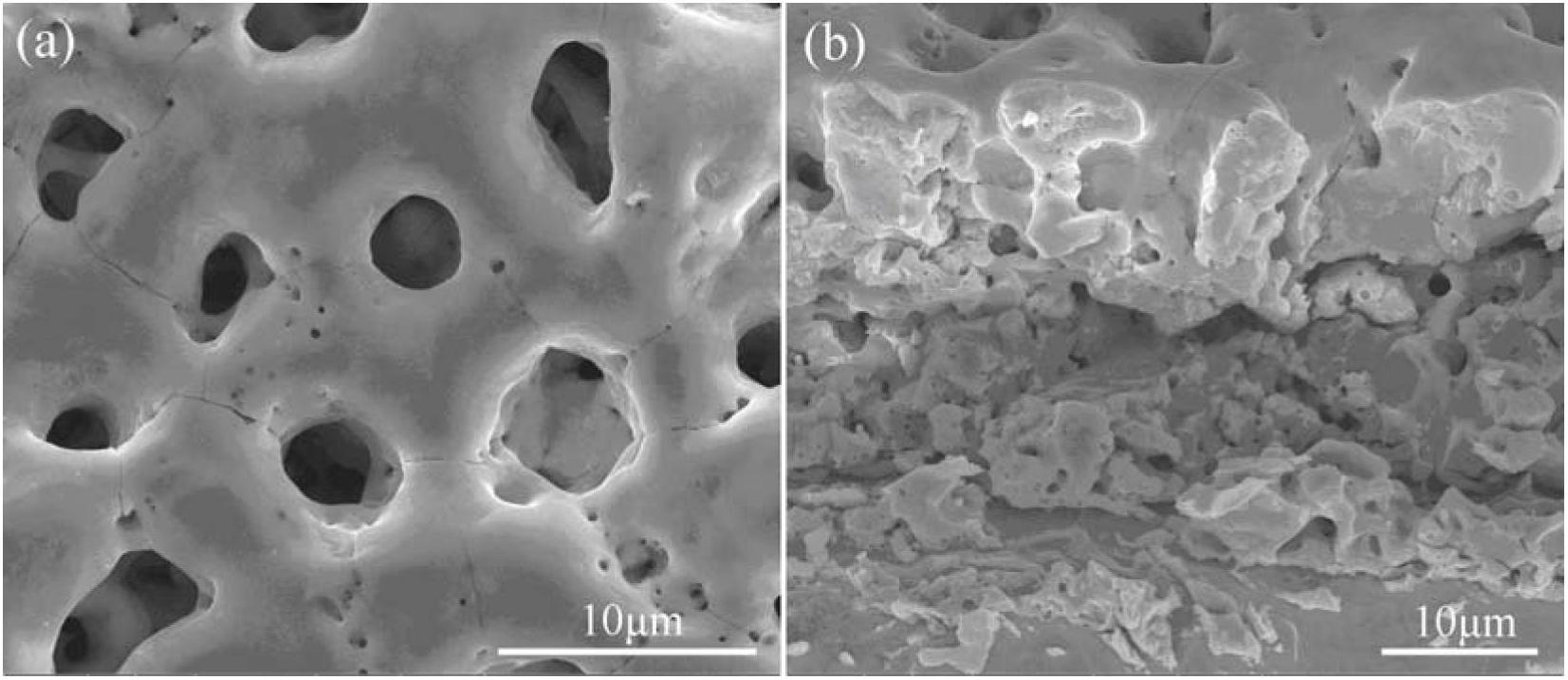

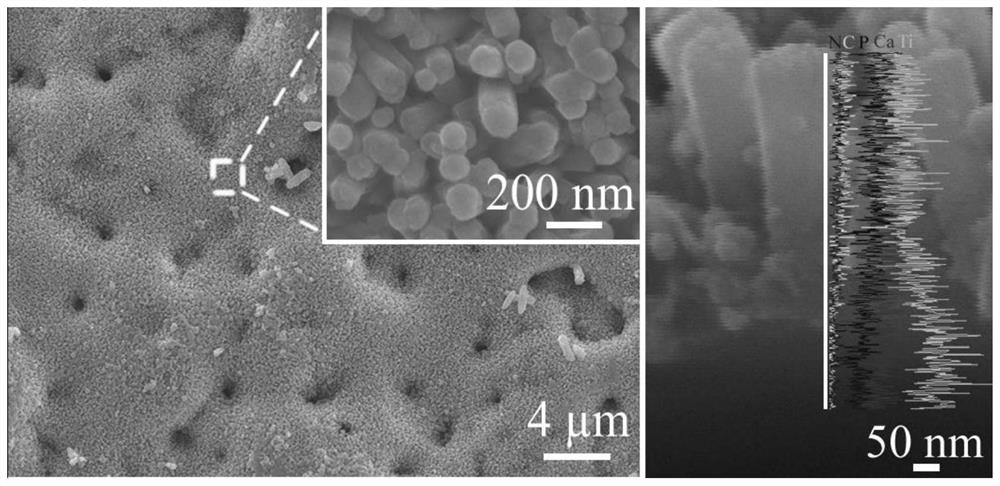

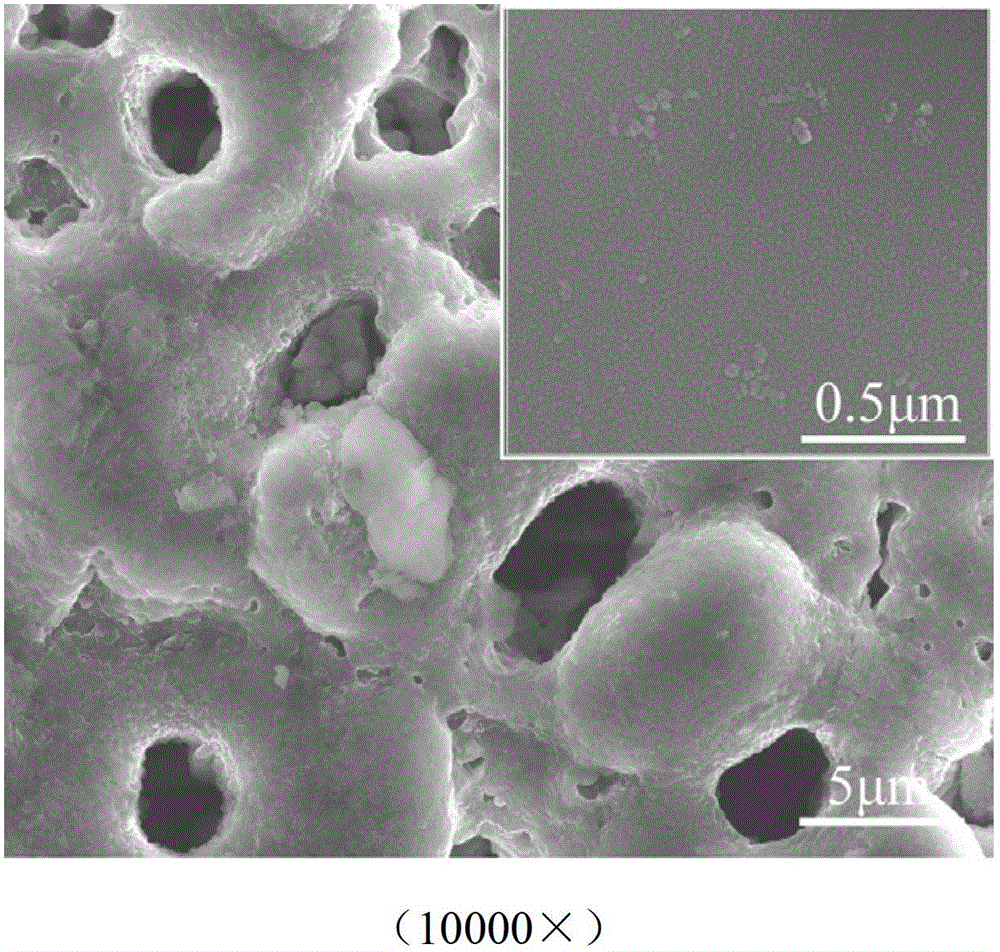

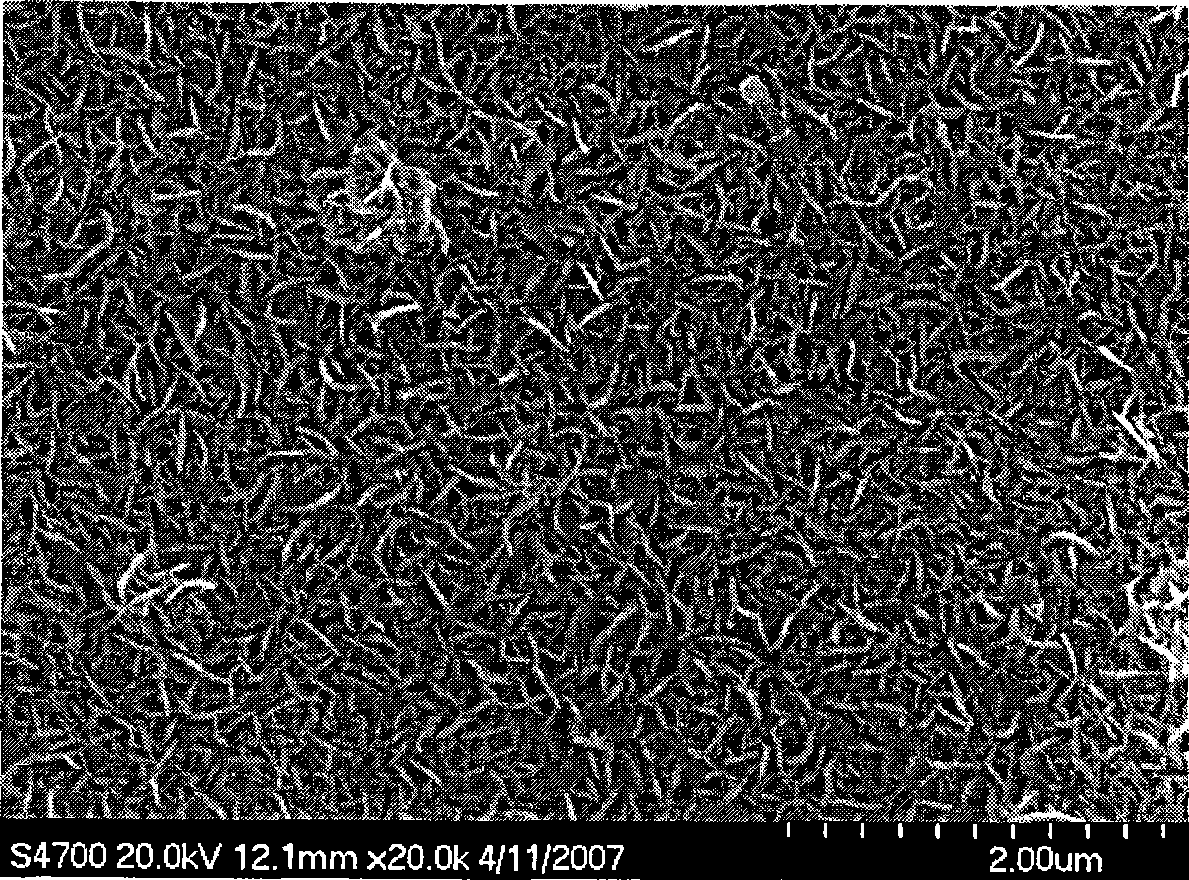

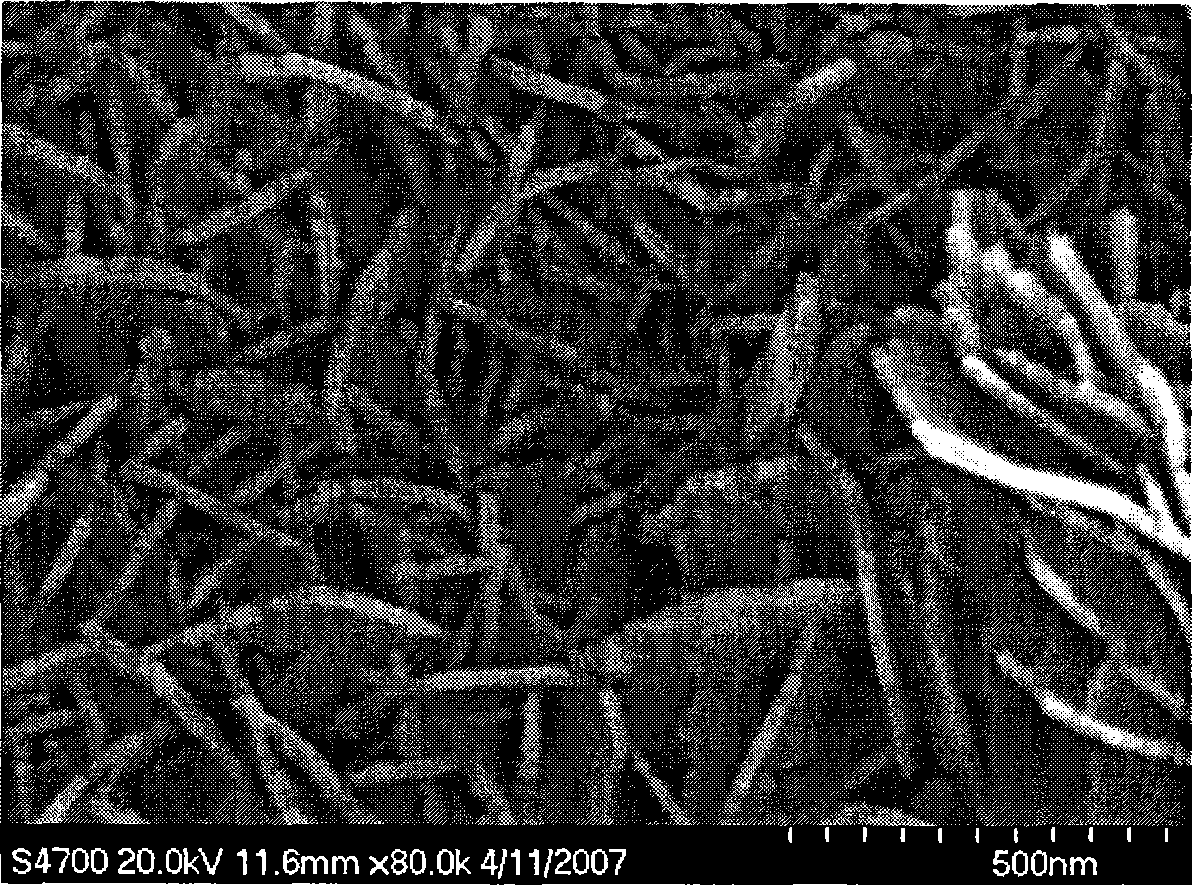

The invention discloses a process for preparing compact magnesium oxide / hydroxyapatite nano fiber double-layer coating on the surface of a magnesium base. The process includes firstly preparing porous magnesium oxide coating containing phosphorus and calcium on the surface of magnesium or magnesium alloy by the microarc oxidation technique, namely utilizing phosphorus and calcium containing water solution as electrolyte, subjecting the magnesium or magnesium alloy to microarc oxidation treatment under high voltage by means of a direct-current pulse power source, and then subjecting the porous magnesium oxide coating containing phosphorus and calcium to hydro-thermal treatment in the specific hydro-thermal environment to obtain the magnesium oxide / hydroxyapatite nano fiber double-layer coating. The magnesium oxide / hydroxyapatite nano fiber double-layer coating obtained has the structure of an inner layer (adjacent to a basal body) composed of magnesium oxide and a small amount of magnesium hydrate and being compact and a surface layer formed by nano fiber hydroxyapatite layer, and has the advantages of high bonding strength, fine biological activity and capability of improving corrosion resistance of the magnesium and magnesium alloy in body fluid evidently. Besides, no discontinuous surfaces exist between the double-layer coating and the basal body.

Owner:XI AN JIAOTONG UNIV

Chemical nickel-plating method on magnesium alloy surface

InactiveCN1500910AReduce pollutionUniform thicknessLiquid/solution decomposition chemical coatingFluorideAqueous solution

The present invention relates to magnesium alloy surface treating technology, and is especially chemical nickel plating process for magnesium alloy. The operation process includes the following steps: activating or finishing magnesium alloy through polishing or grinding, degreasing and acid pickling with acid fluoride bearing solution at 20-60 deg.c for 0.5-5 min; pre-treating with water solution containing fluoride bearing compound, iron bearing compound and complex at 15-45 deg.c for 5-30 min; and chemically nickel plating. The said process can make chemical nickel coating with homogeneous thickness, firm combination with substrate, high corrosion resistance and metal appearance. The process of the present invention has low cost and less environmental pollution and is suitable for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

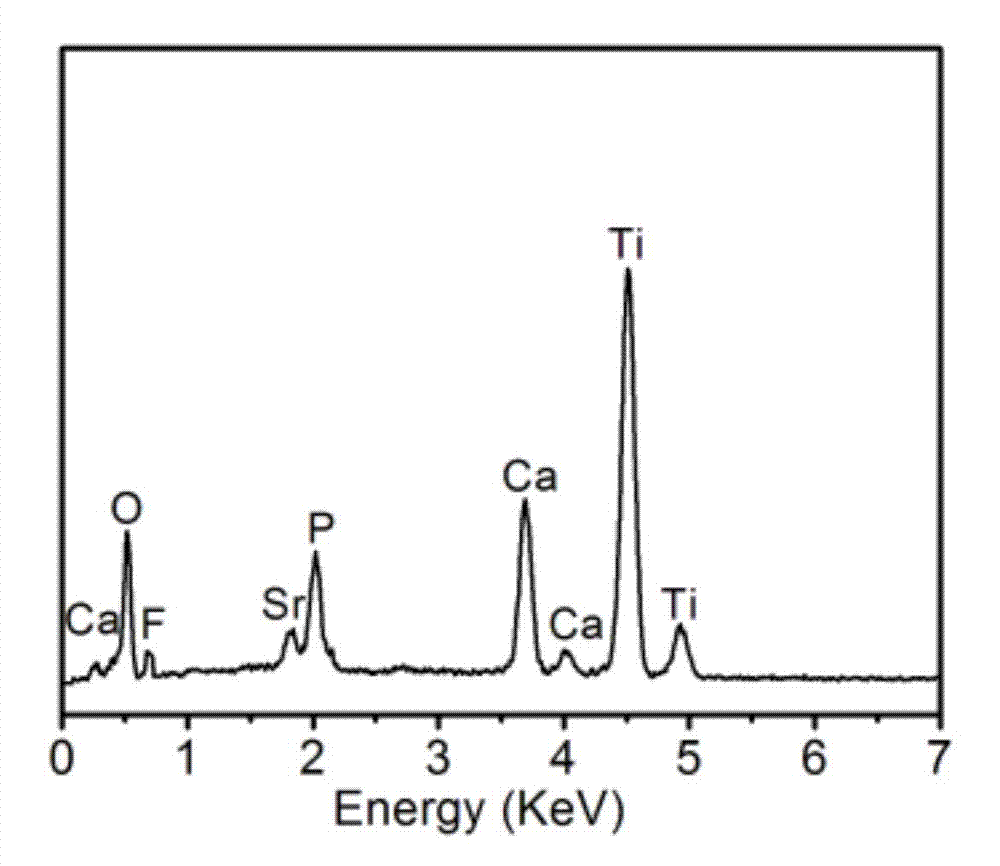

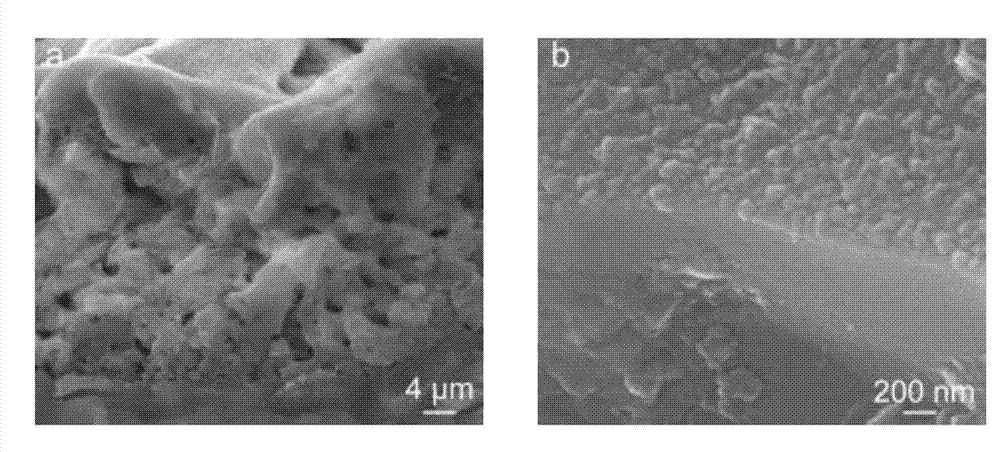

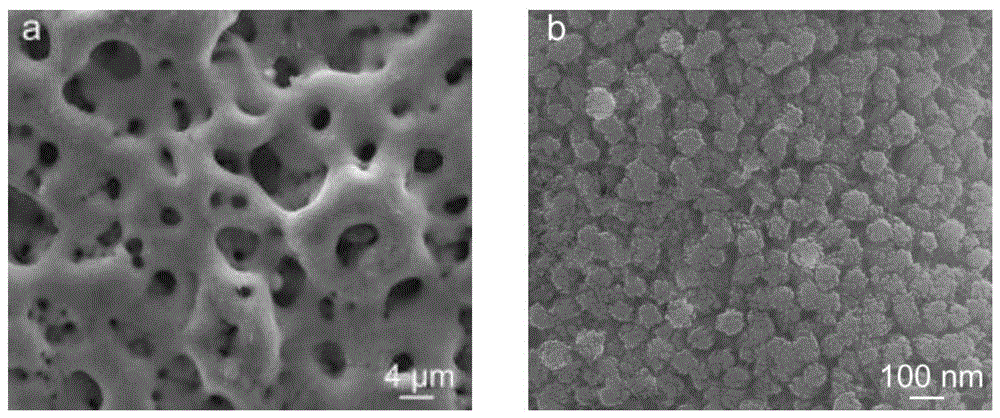

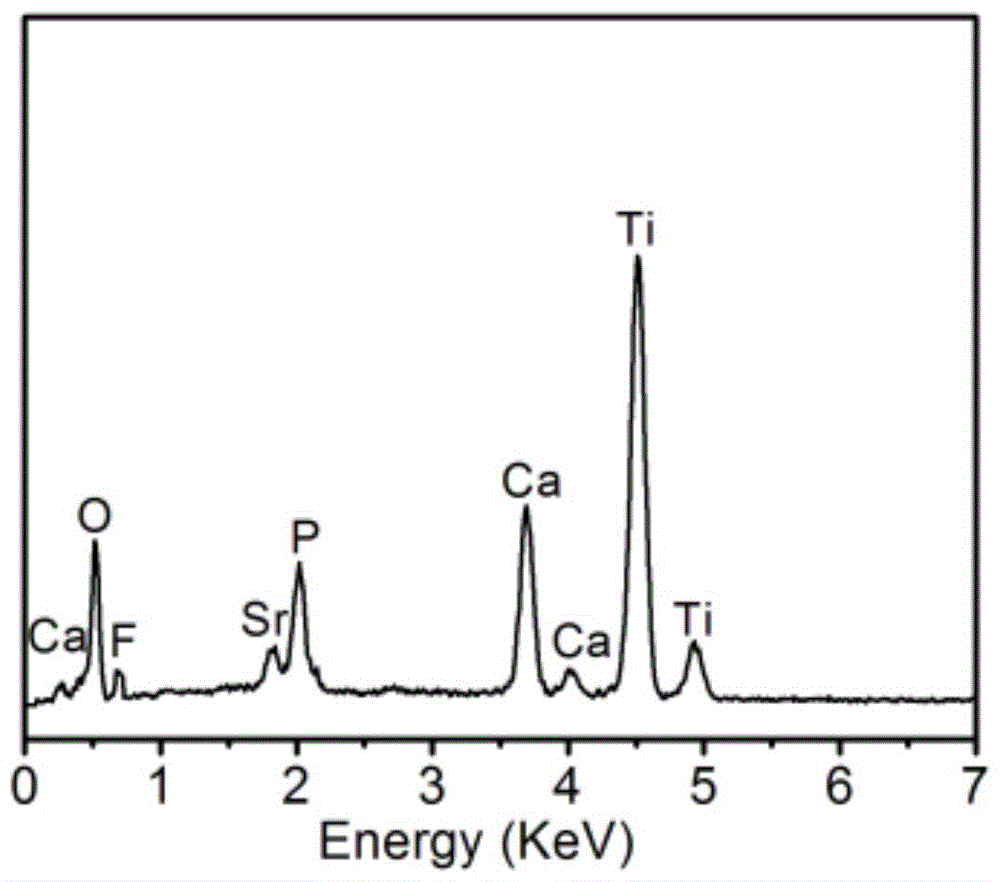

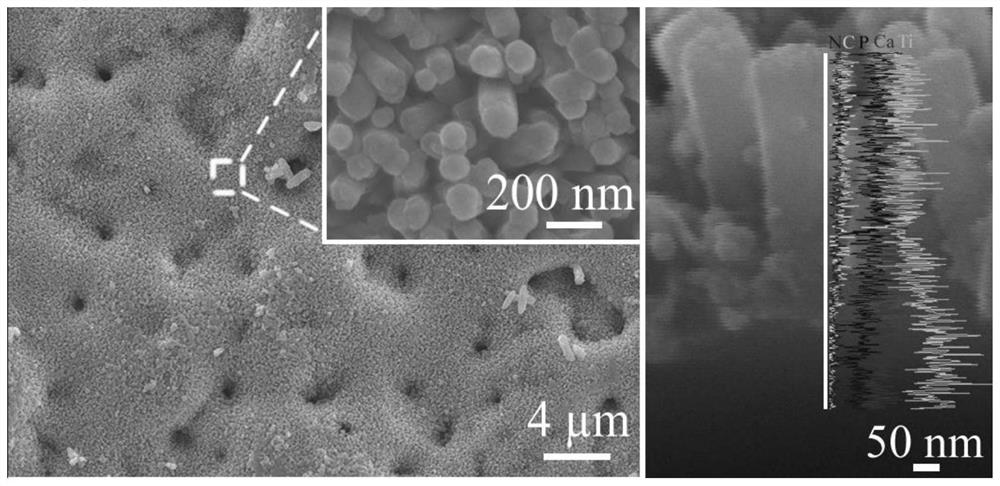

Titanium dioxide/strontium and fluorine-containing hydroxyapatite bioactive nano-composite coating as well as preparation method and application thereof

ActiveCN104726921AEase of mass productionSimple and fast operationSurface reaction electrolytic coatingProsthesisSolubilityPlasma electrolytic oxidation

The invention provides a titanium dioxide / strontium and fluorine-containing hydroxyapatite bioactive nano-composite coating as well as a preparation method and an application thereof. The method comprises the following steps: firstly preparing an electrolyte containing calcium ions, strontium ions, fluorine ions and phosphate anions; and then by taking titanium or a titanium alloy as an anode and stainless steel as a cathode, directly preparing the titanium dioxide / strontium and fluorine-containing hydroxyapatite bioactive nano-composite coating on the surface of a titanium or titanium alloy substrate by virtue of a micro-arc oxidation technology. The coating consists of an inner layer combined on the surface of the substrate and a surface layer combined on the surface of the inner layer, wherein the inner layer is a titanium dioxide layer in a form of a nano crystal and the surface layer is a nano-particle strontium and fluorine-containing hydroxyapatite layer. No non-continuous interfaces are available between the coating and the substrate and the coating has high combining strength and structural stable performance; the coating is relatively small in solubility in a simulated body fluid, so that the coating is effectively implanted and used; and the nano-particle strontium and fluorine-containing hydroxyapatite layer in the surface layer can remarkably promote the osteogenic function of the cells to form new bones and inhibit bacterial adhesion and growth.

Owner:宝鸡卡斯特医疗科技有限公司

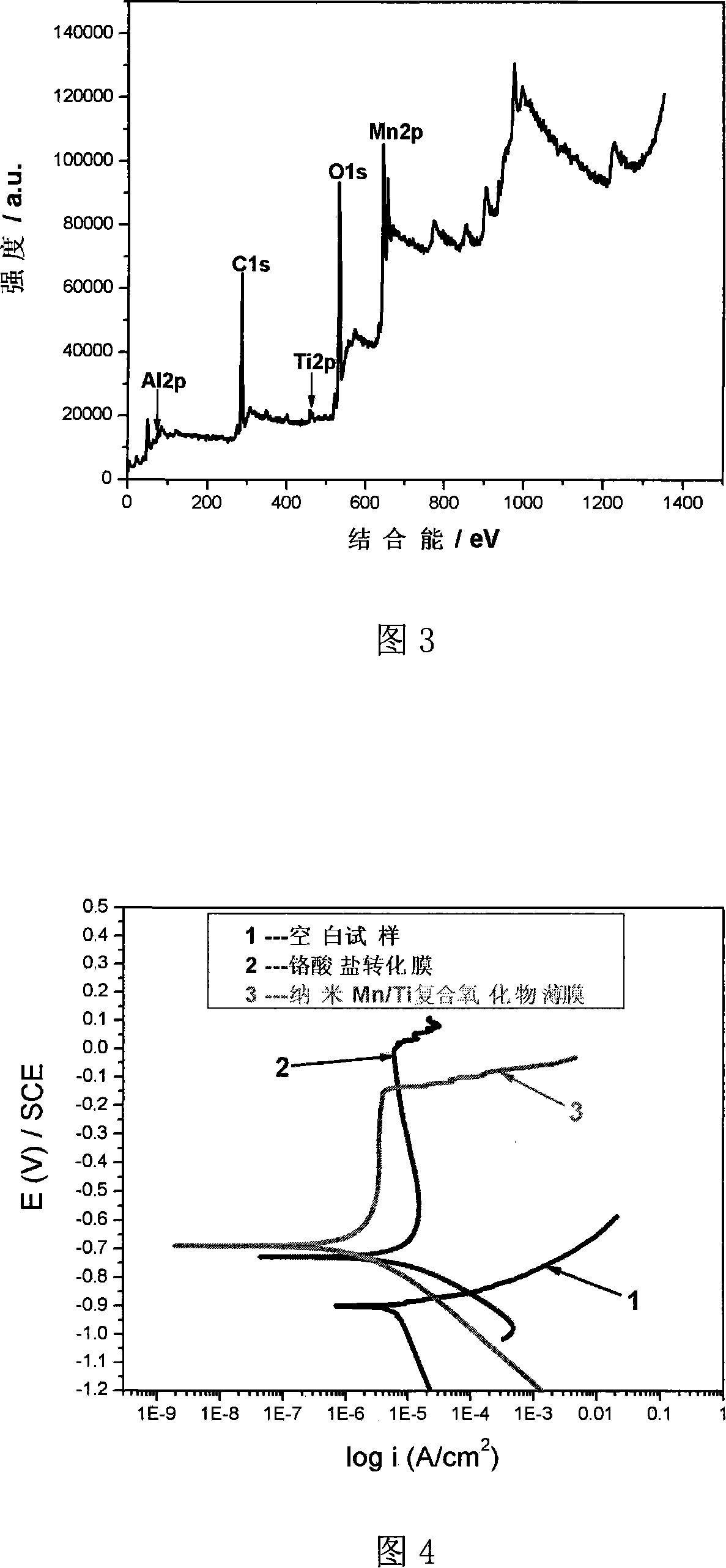

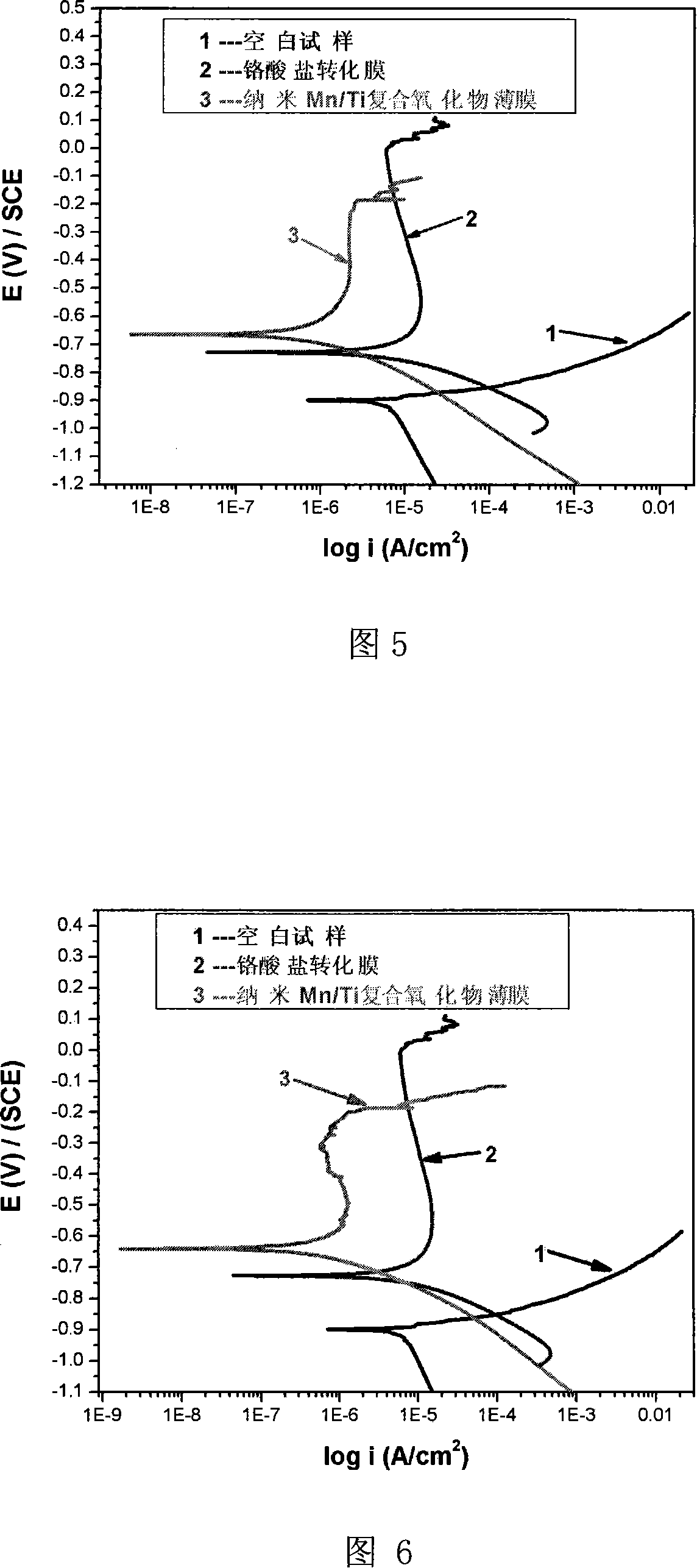

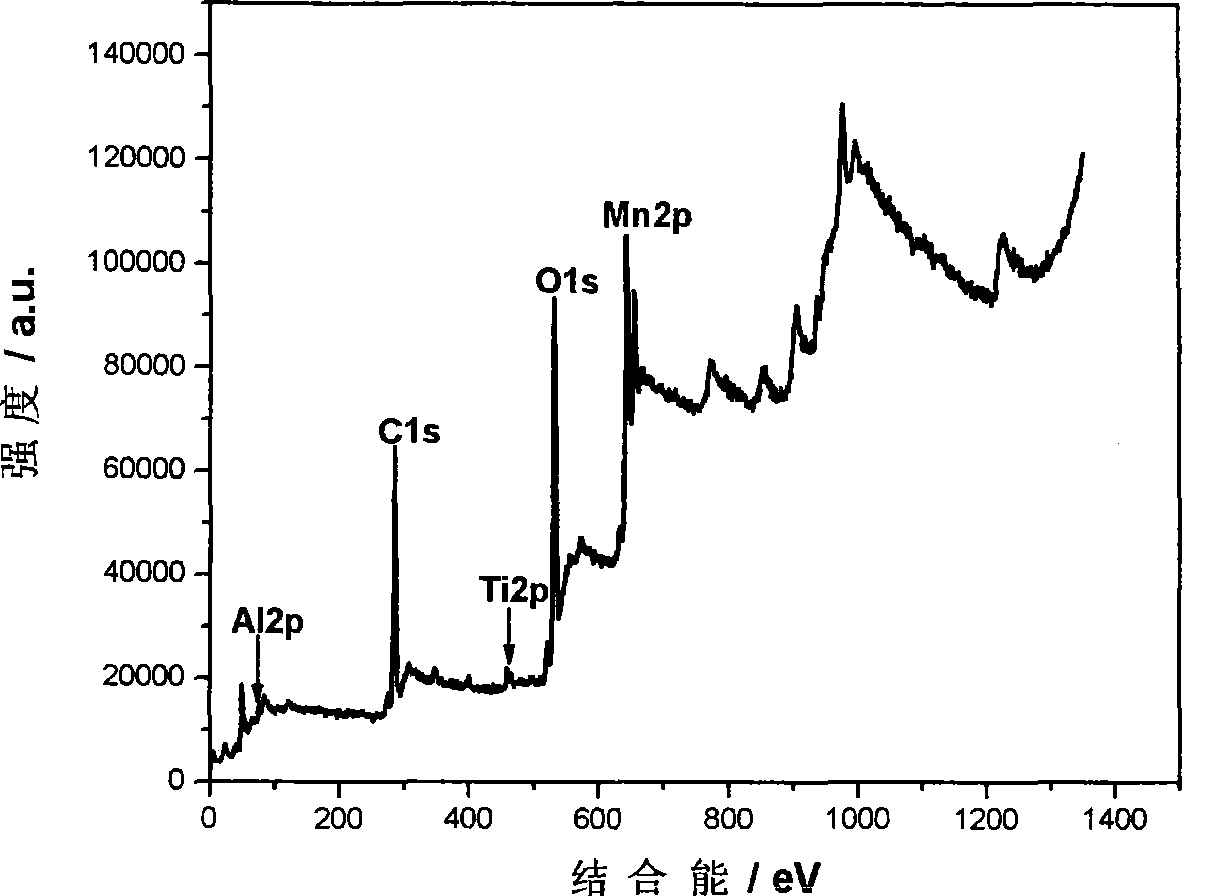

Chemical treatment method for aluminum alloy surface

InactiveCN101122017ASimple ingredientsEasy to controlMetallic material coating processesPotassium permanganateCompound (substance)

An aluminum alloy surface chemical method belongs to the fine chemical field. The treatment method is to put the aluminum alloy into the bath liquid containing potassium permanganate 0.01 to 10g / L, titanous sulfate 0.01 to 5g / L, wetter sodium dodecylbenzene sulfonate 0.1 to 10g / L, with the pH value being 1 to 4, and the temperature of 40 to 90DEG C to treat for 1 to 8 minutes, and then seal with boiled water for 20 to 30 minutes, and finally an even, fine golden conversion film with certain thickness is obtained on the surface of the aluminum alloy. The conversion film has excellent corrosion resistance performance. The invention can well solve the problems that products or emission during or after treatment of the current chromate solution to the aluminum alloy surface contain sexivalent chromium, which severely pollute the environment and harm the health of human body, etc; and the corrosion resistance of the invention is equal to that after treatment by the chromate solution.

Owner:BEIJING UNIV OF CHEM TECH

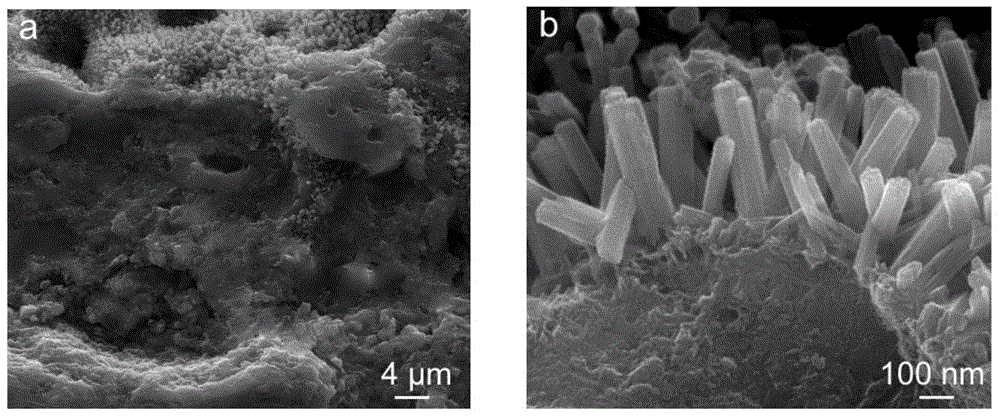

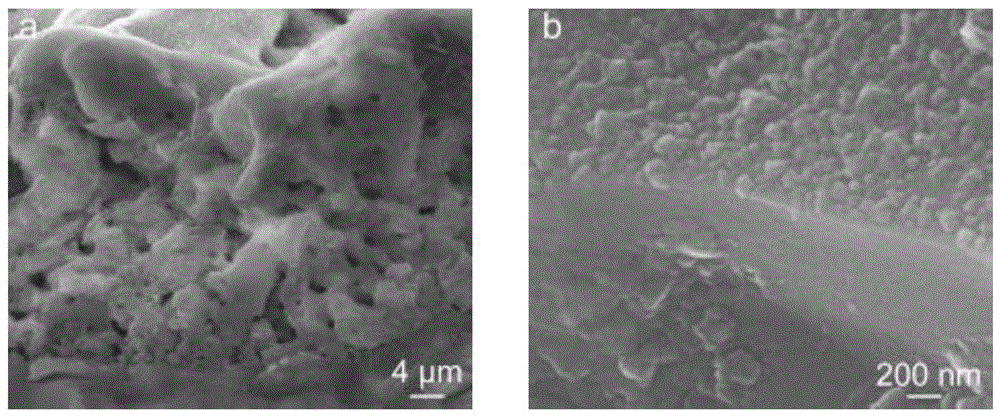

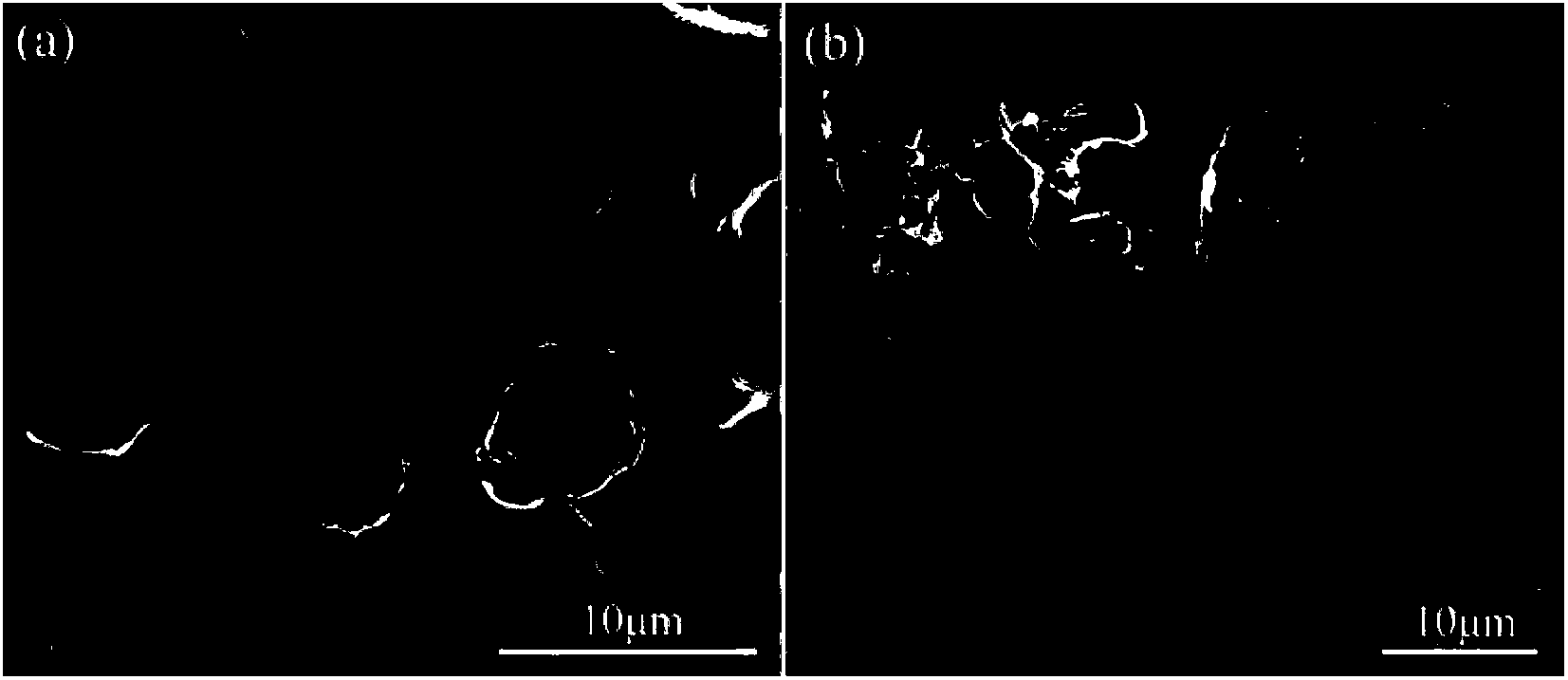

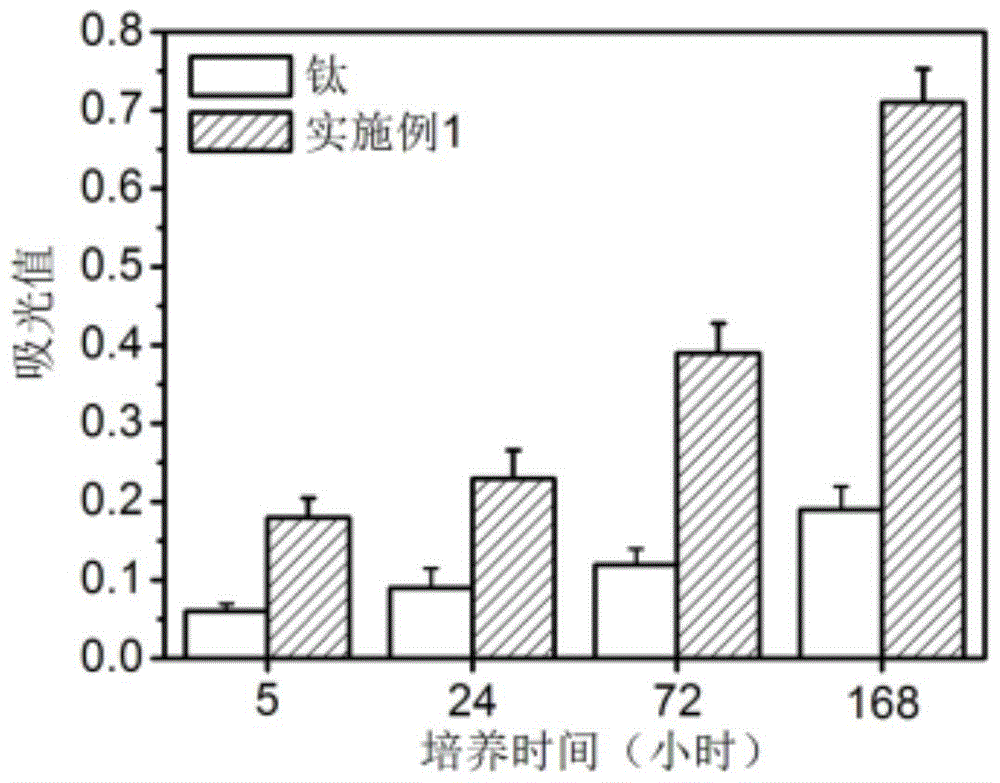

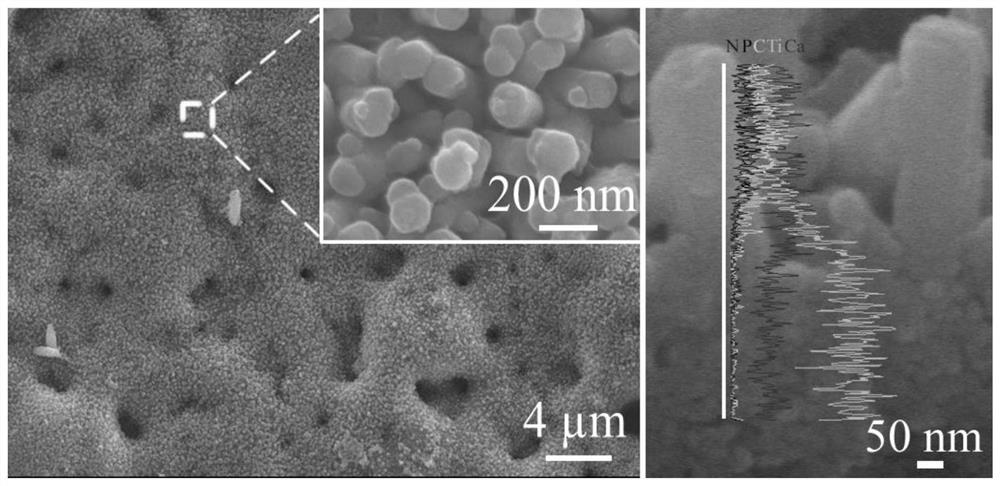

Titanium-based surface antibacterial and bone tissue regeneration induced functional coating as well as preparation method and application thereof

ActiveCN104645414AEase of mass productionSimple ingredientsSurface reaction electrolytic coatingProsthesisElectrolytic agentMicro arc oxidation

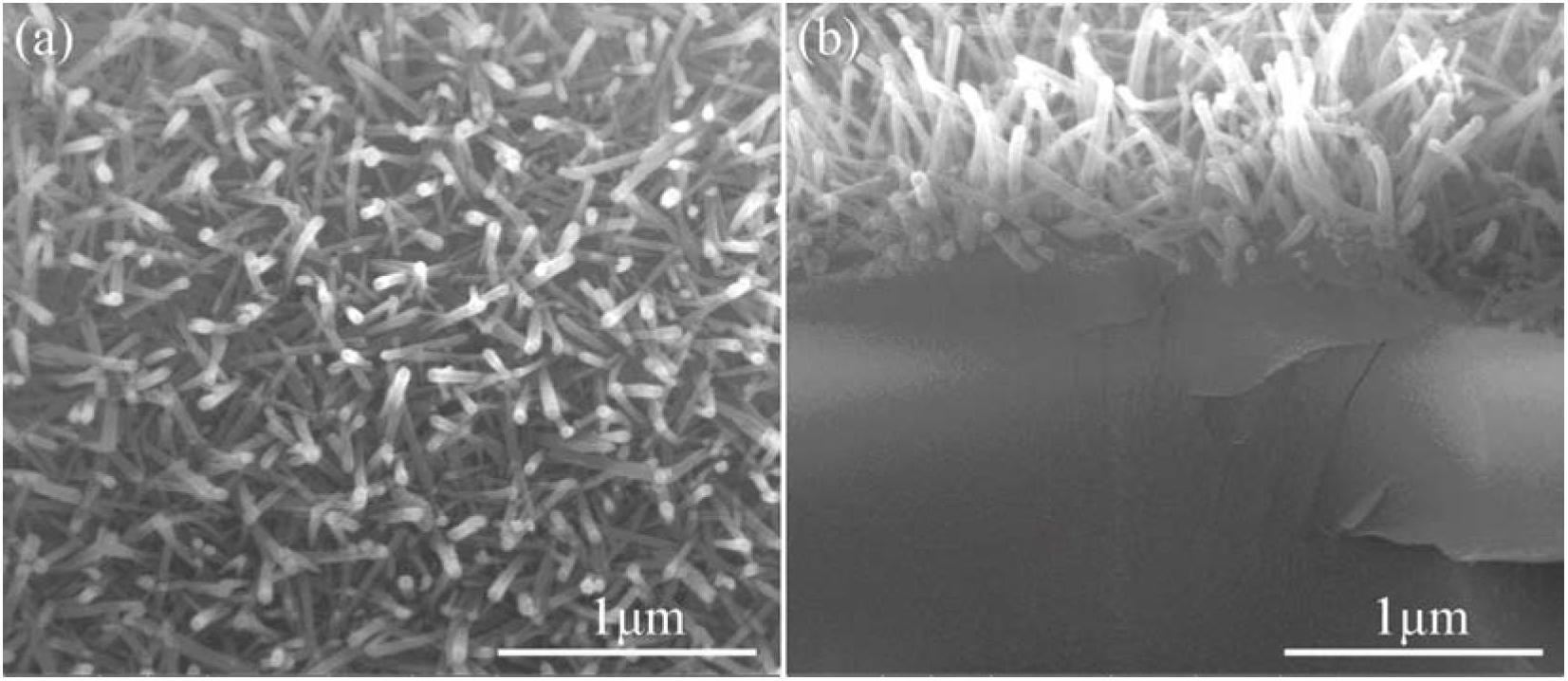

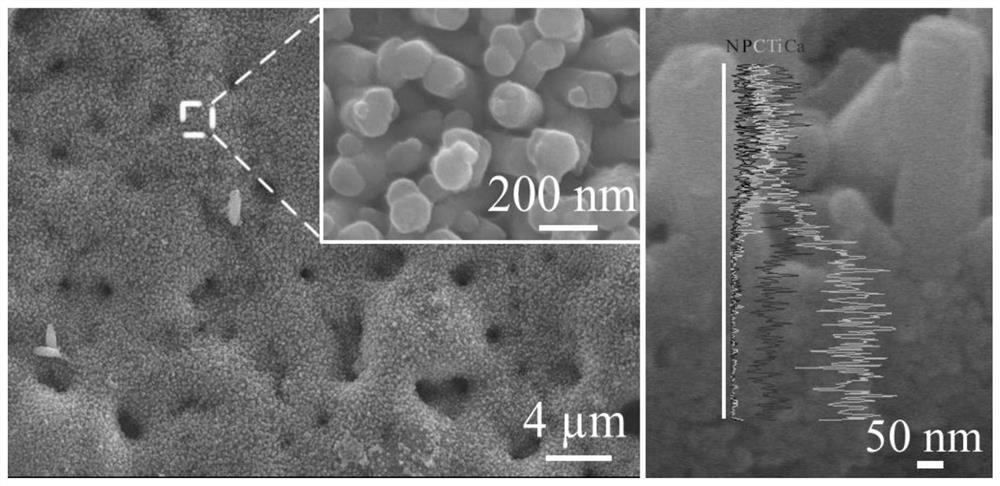

The invention provides a titanium-based surface antibacterial and bone tissue regeneration induced functional coating as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly preparing an electrolyte, taking titanium or a titanium alloy as an anode and taking stainless steel as a cathode, preparing a porous TiO2 coating containing calcium, phosphorus and strontium by adopting a micro-arc oxidation technology, then sequentially performing hydro-thermal treatment by virtue of a fluorine-containing solution, and also loading human bone morphogenetic protein-2 to finally obtain a target coating disclosed by the invention, wherein the coating consists of an inner layer which is bonded on the surface of a matrix and a surface layer which is bonded on the surface of the inner layer, the inner layer is a porous TiO2 layer containing calcium, phosphorus and strontium, and the surface layer is a three-dimensional nano-fibrous hydroxyapatite layer which is loaded with human bone morphogenetic protein-2 and contains strontium and fluorine. No non-continuous interface is formed between the coating and the matrix, so that the coating provided by the invention has relatively good bonding strength and structure stability performance, also has good antibacterial and bone tissue regeneration inducing functions, and can be used for significantly promoting the osteogenic function of cells, promoting new bone formation and inhibiting the adhesion and growth of bacteria.

Owner:宝鸡卡斯特医疗科技有限公司

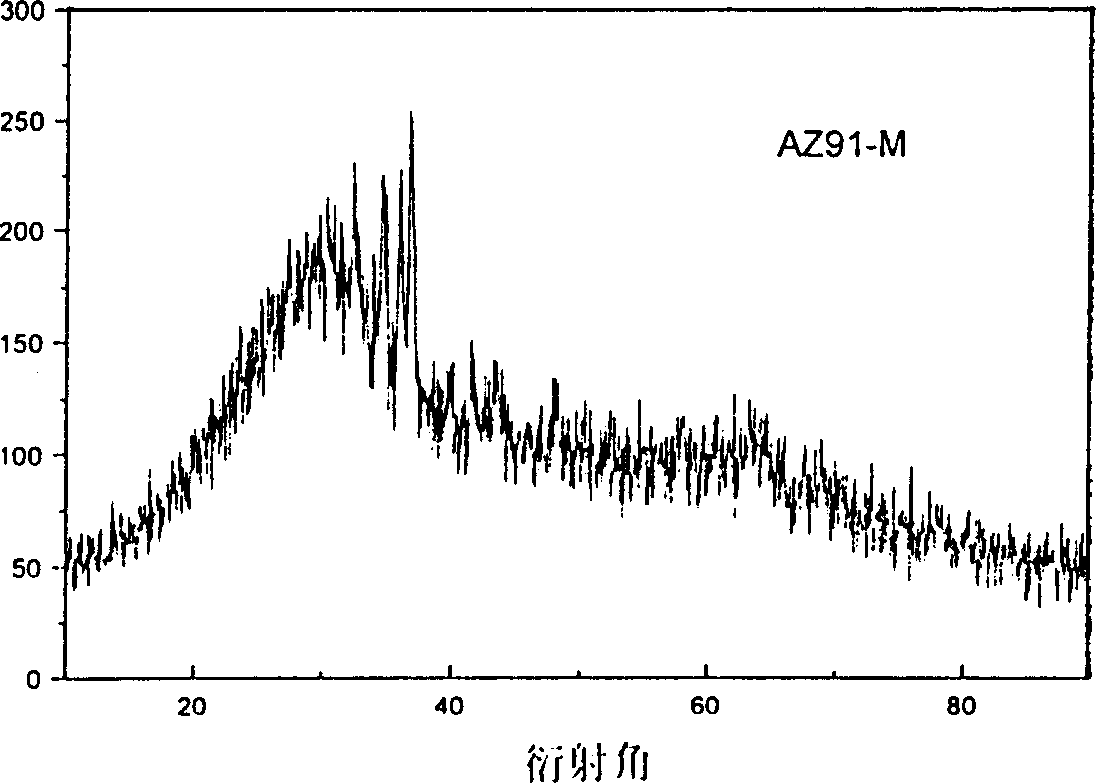

Magnesium radical differential arc oxidization electrolytic solution and its differential arc oxidation process

InactiveCN101113529AProcess stabilitySimple ingredientsAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a magnesium matrix microarc oxidation electrolyte liquid and a microarc oxidation method thereof. The electrolyte liquid comprises: 3 - 40g / L of fluozicronate, 0.5 - 10 g / L of oxalate, 2 - 20 g / L of phosphoric acid, 1 - 20 g / L of acetate, 3 - 30 g / L of phosphate, 0.5 - 10 g / L of fluoride. The operation method is that: a magnesium workpiece is taken as anode, stainless steel is taken as cathode, a pulse power supply is adopted, constant voltage is 350 - 650V, frequency is 50 - 2000Hz, duty ratio is 10 - 40 percent, and the electrolyte liquid is oxidated through microarc under the condition that the distance between a cathode plate and an anode plate is 8 - 12 cm, the temperature of the electrolyte liquid is kept for 10 - 40 DEG C with the treatment time of 5 - 90min. the electrolyte liquid of the invention does not comprise Cr6+, thus having not too large pollution to environment; the obtained film layers which consists of anti-corrosive substances have the advantages of smooth surface, ceramics appearance, strong combination, comparatively larger thickness, high density and little pores, high hardness, etc.

Owner:XI AN JIAOTONG UNIV

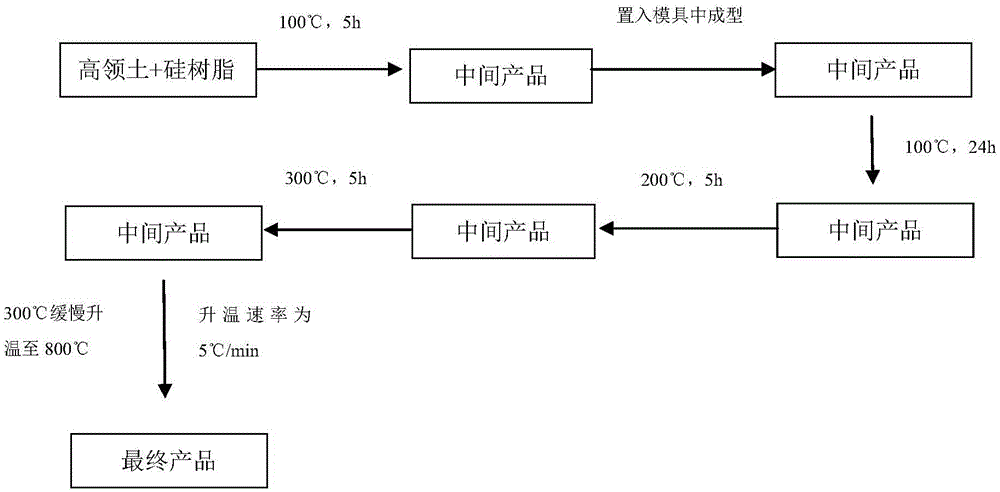

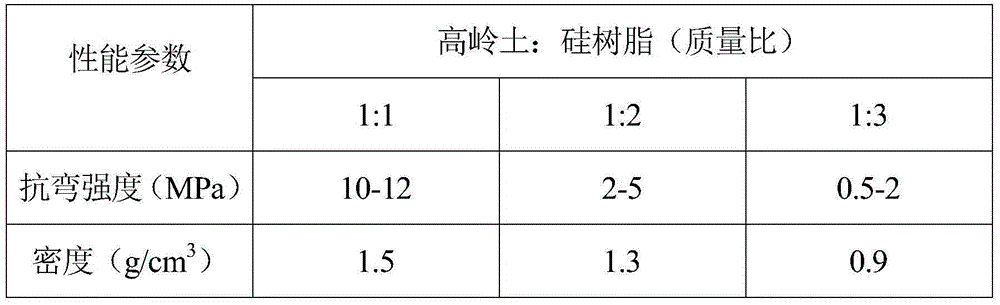

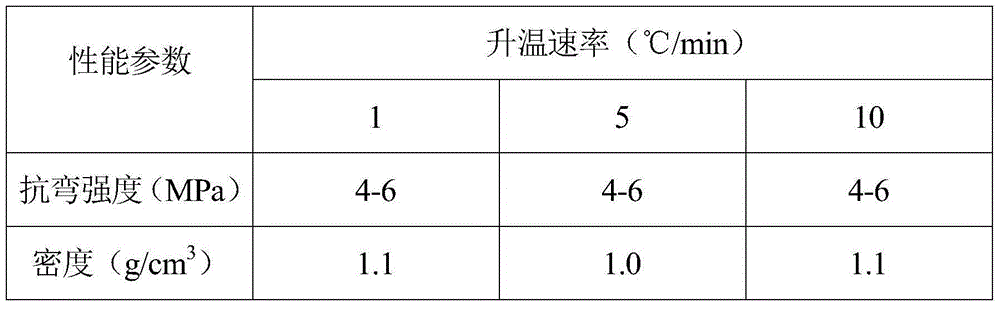

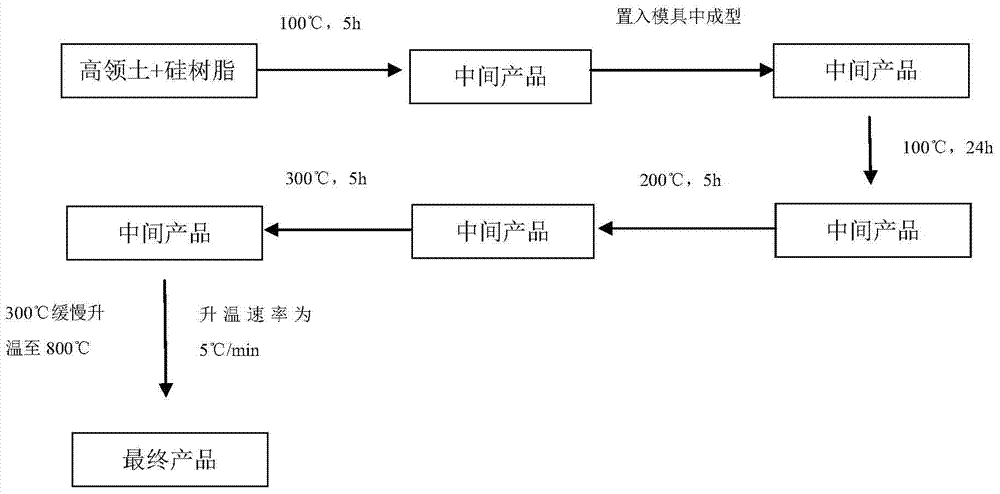

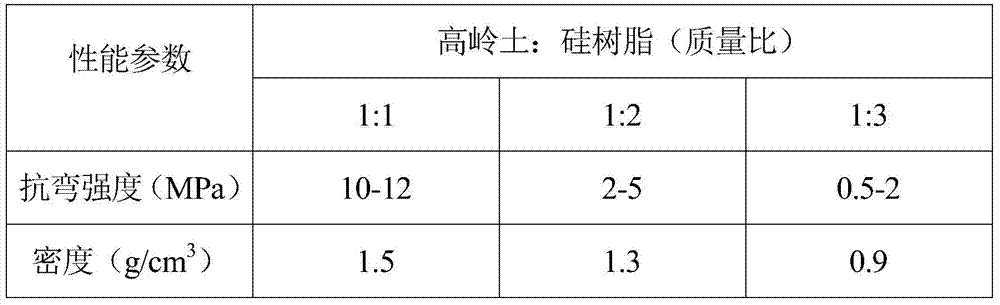

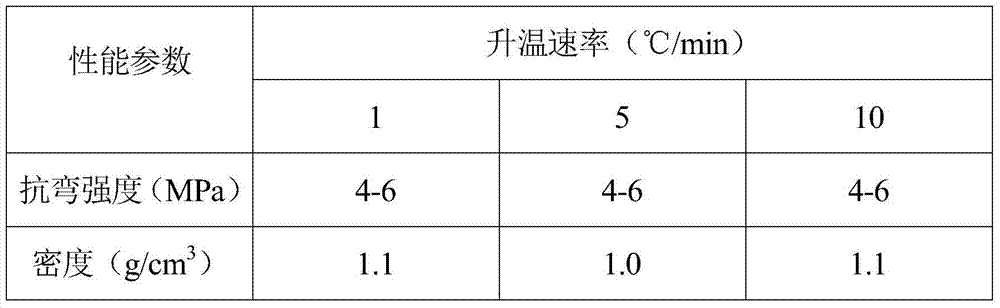

Fire resistant material and preparation method thereof

The invention discloses a fire resistant material and a preparation method thereof, in particular to a silicon dioxide-containing fire resistant material and a preparation method thereof. The fire resistant material is prepared by adopting an organosilicon polymer as a base body and an inorganic additive as an additive under a condition of slowly warning up. The fire resistant material and the preparation method thereof can be used for preparing a series of high temperature resisting material articles such as high-temperature service liners, high temperature vessels and refractory bricks, and solve a series of problems of existing refractory material products that preparation technology energy consumption is great, components are complex, components which are unstable or are easily volatilized and decomposed under high temperature action are contained, and the like.

Owner:SOUTHEAST UNIV

Method for electroplating zinc-nickel coating on magnesium alloy electroplate surface

InactiveCN104233416AWeak corrosiveCorrosion freeMetallic material coating processesPotassium fluoridePhosphoric acid

The invention relates to a method for electroplating a zinc-nickel coating on a magnesium alloy electroplate surface. The method employs a novel pickling activation and zinc immersion pre-treatment technology, wherein an acid solution is the complex formulation solution, the acid solution comprises 10-14g / L oxalic acid, 40-60g / L sodium fluoride, 5-25ml / L phosphoric acid, 2-25g / L ammonium bifluoride and 0.005-5g / L sodium dodecanesulphonate. The activation temperature is 25-35 DEG C, the activation time is 1-5 minutes; wherein the sulfate zinc-immersion technology comprises the following steps: immersing in a zinc-immersion solution comprising 30g of 20-40g / L of zinc sulfate, 5g of 3-7g / L sodium carbonate or potash, 7g of 2-4g / L potassium fluoride and 150g of 100-120g / L potassium pyrophosphate for zinc immersion, wherein the pH of the zinc-immersion solution is between 10.2 and 10.4, the zinc immersion temperature is from 30 DEG C to 70-80 DEG C, wherein the zinc immersion time is 10-15 minutes, and then obtaining the compact and uniform zinc-immersion layer as a base coat for subsequent electroplating. The combination capacity of the coating and a matrix can be increased.

Owner:无锡市森信精密机械厂

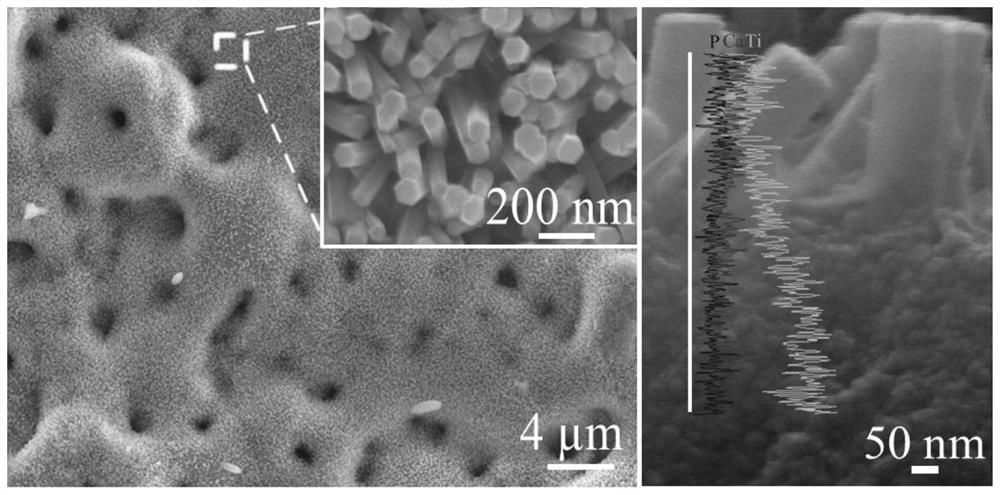

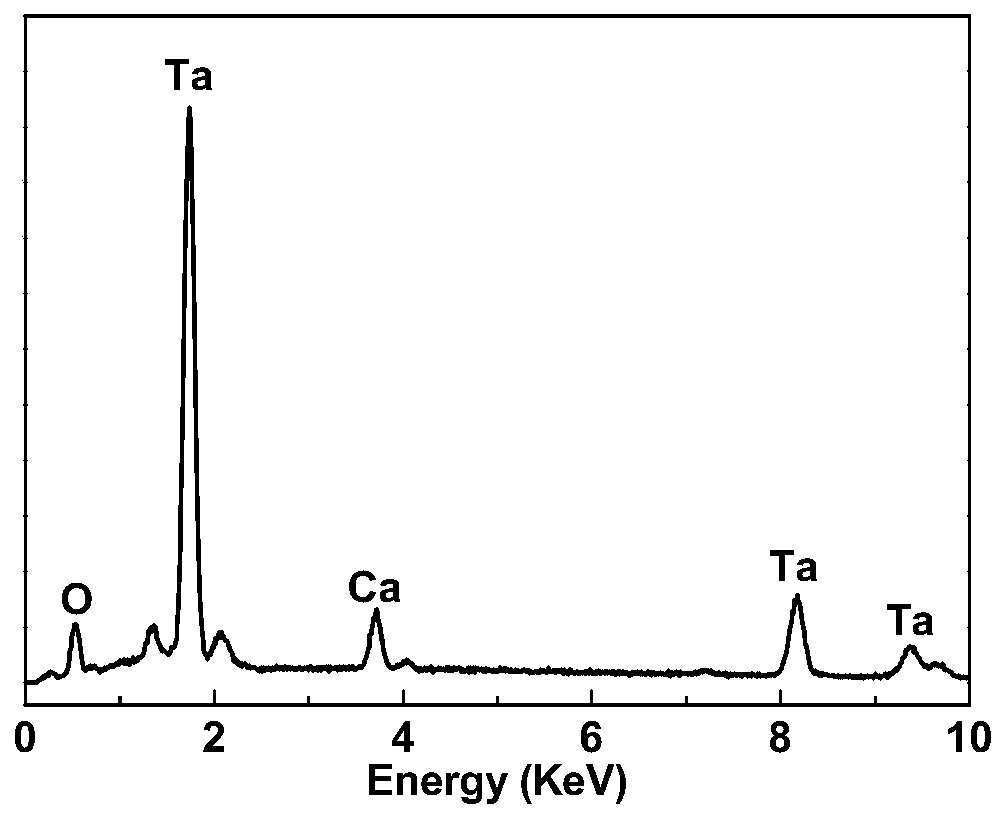

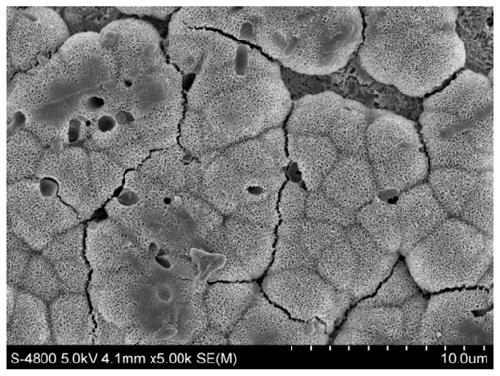

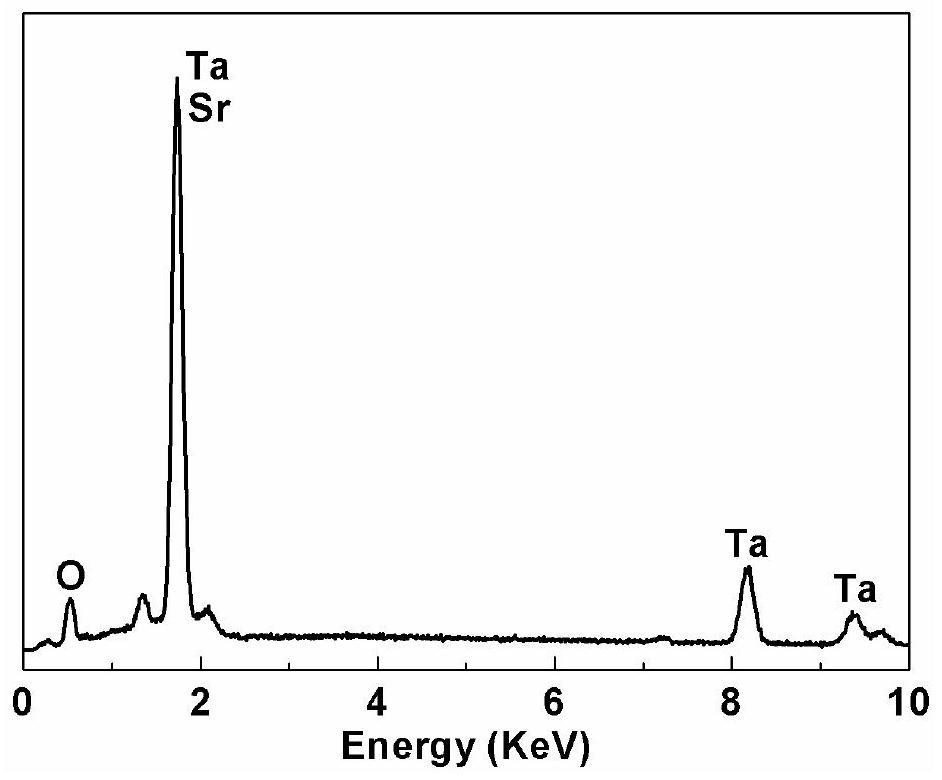

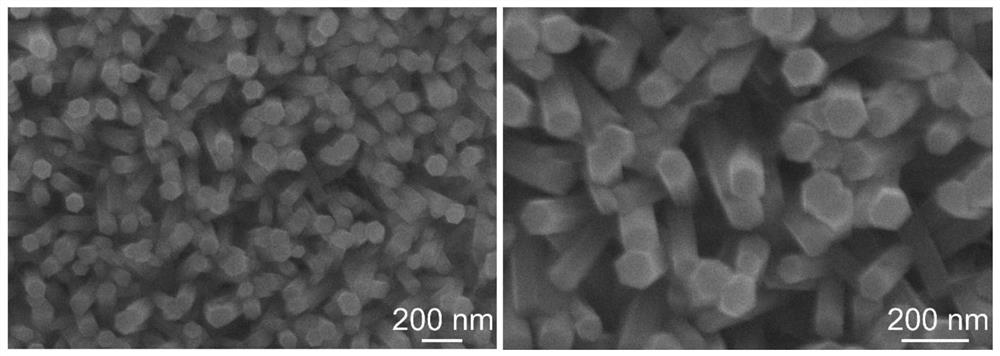

Preparation technology of porous calcium gluconate tantalite/nono-funicular hydroxylapatite bioactive coating

InactiveCN102644078ASimple ingredientsEasy to controlSuperimposed coating processPlasma electrolytic oxidationMicro arc oxidation

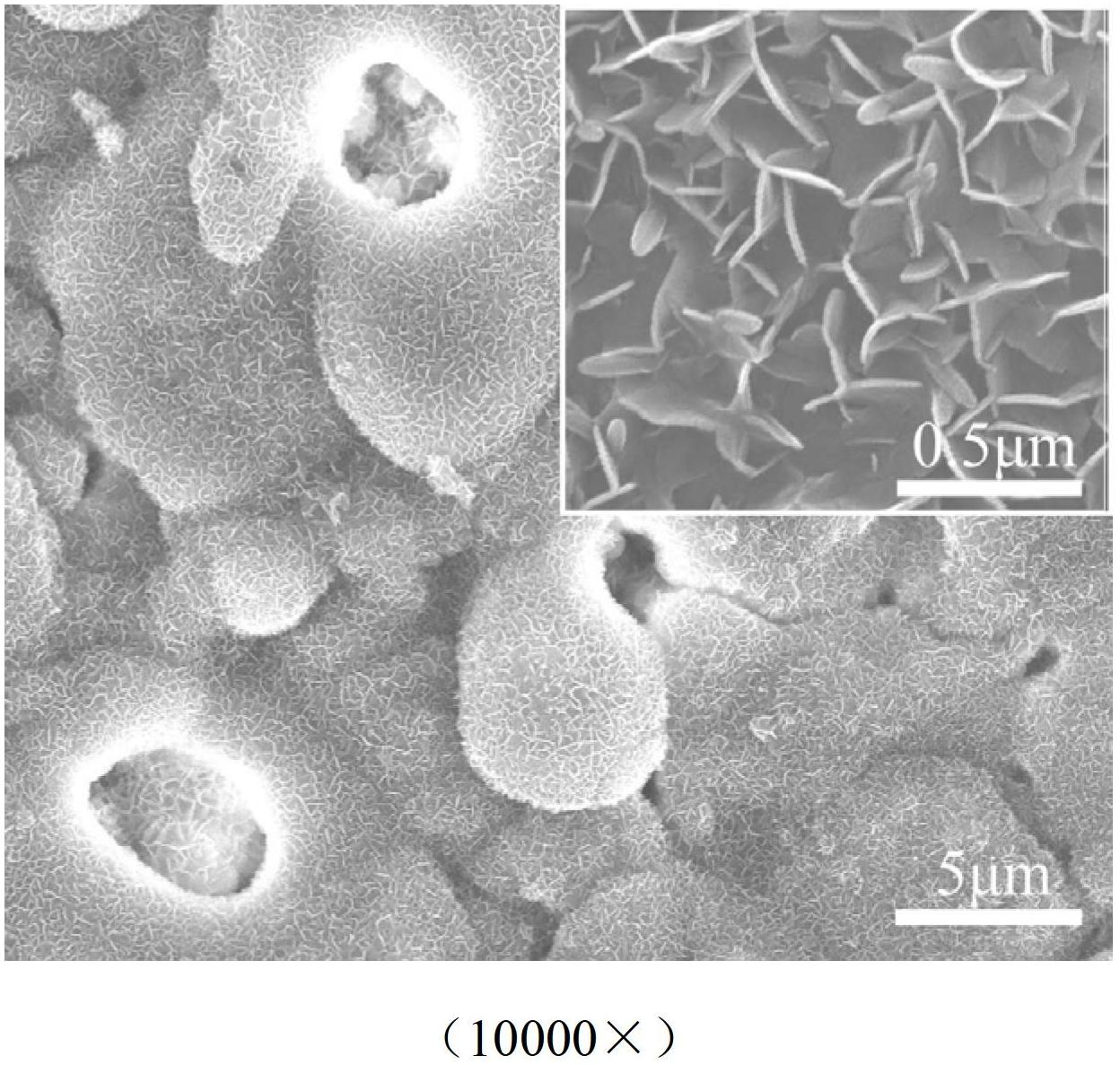

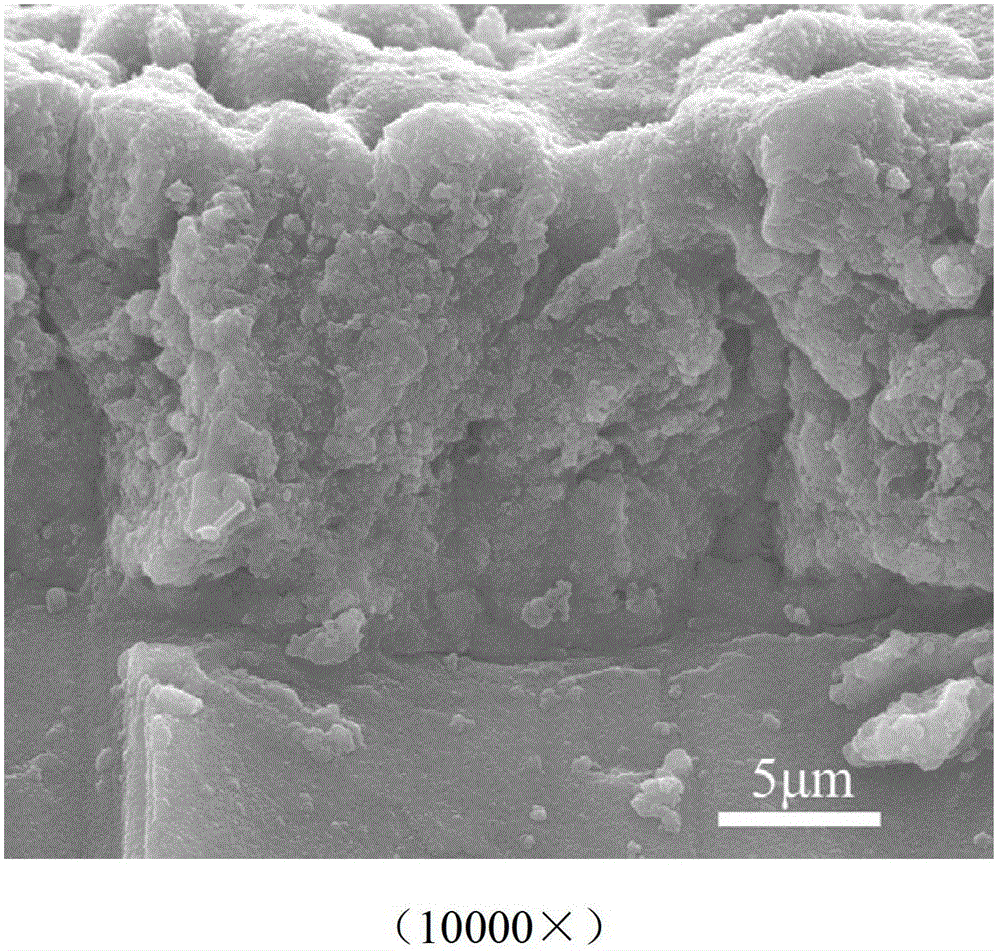

The invention discloses a preparation technology of porous calcium gluconate tantalite / nono-funicular hydroxylapatite bioactive coating. The preparation technology comprises the following step of firstly preparing calcium and phosphorus-containing gluconate tantalite-based complex phase layer on the surface of tantalite by a micro arc oxidation technology, i.e. taking calcium and phosphorus-containing water solution as electrolyte, carrying out the micro arc oxidation treatment on the tantalum under high voltage by using a pulse power source, and carrying out the hydro-thermal treatment on the calcium and phosphorus-containing gluconate tantalite-based complex phase layer under a special hydro-thermal environment condition. The obtained coating with a double-layer structure has the following structure and performance characteristics: an inner layer (which is adjacent to a base body) is a gluconate tantalite-based complex phase layer which consists of gluconate tantalite, and a trace amount of antalum pentoxide and tantalum monoxide and is of a microporous structure in shape; and a surface layer is nono-funicular hydroxylapatite, which is inclined to or in parallel with the gluconate tantalite-based complex phase layer. No incontinuous interface exists between the coating with the double-layer structure and the base body, so that the coating is high in combining strength, and the osteolith can be quickly formed in the pseudo body fluid environment in an inducing way, so that the coating is good in biological activity.

Owner:XI AN JIAOTONG UNIV

Nanorod array coating with thermal control immunity and antioxidant functions as well as preparation method and application of nanorod array coating

ActiveCN112169023AProcess stabilityThe process is simple and easy to controlSurface reaction electrolytic coatingPharmaceutical delivery mechanismMicro arc oxidationOxidation resistant

The invention discloses a nanorod array coating with thermal control immune and antioxidant functions as well as a preparation method and application of the nanorod array coating, and belongs to the technical field of biomedical materials. The preparation method comprises the following steps of firstly, preparing a porous titanium dioxide coating containing phosphorus and calcium on the surface layer of titanium or an alloy thereof by adopting a micro-arc oxidation process, and then growing a hydroxyapatite nanorod configuration coating in situ on the porous titanium dioxide coating containingphosphorus and calcium by adopting a hydrothermal treatment method; and finally, preparing a polydopamine-coated hydroxyapatite nanorod array by using an oxidation auto-polymerization method to finally obtain the nanorod array coating with both thermal control immunity and antioxidant functions. The process is stable, and the controllability is high. The surface layer of the prepared biomedical material has dual effects of oxidation resistance and photo-thermal property at the same time. As an implant, the implant can heal and regenerate bone tissue, and avoids coating peeling induced by poormembrane / base binding force and side reactions such as osteolysis or excessive inflammation induced by the coating peeling and the like.

Owner:XI AN JIAOTONG UNIV

Film forming solution for magnesium alloy chromeless chemical conversion film

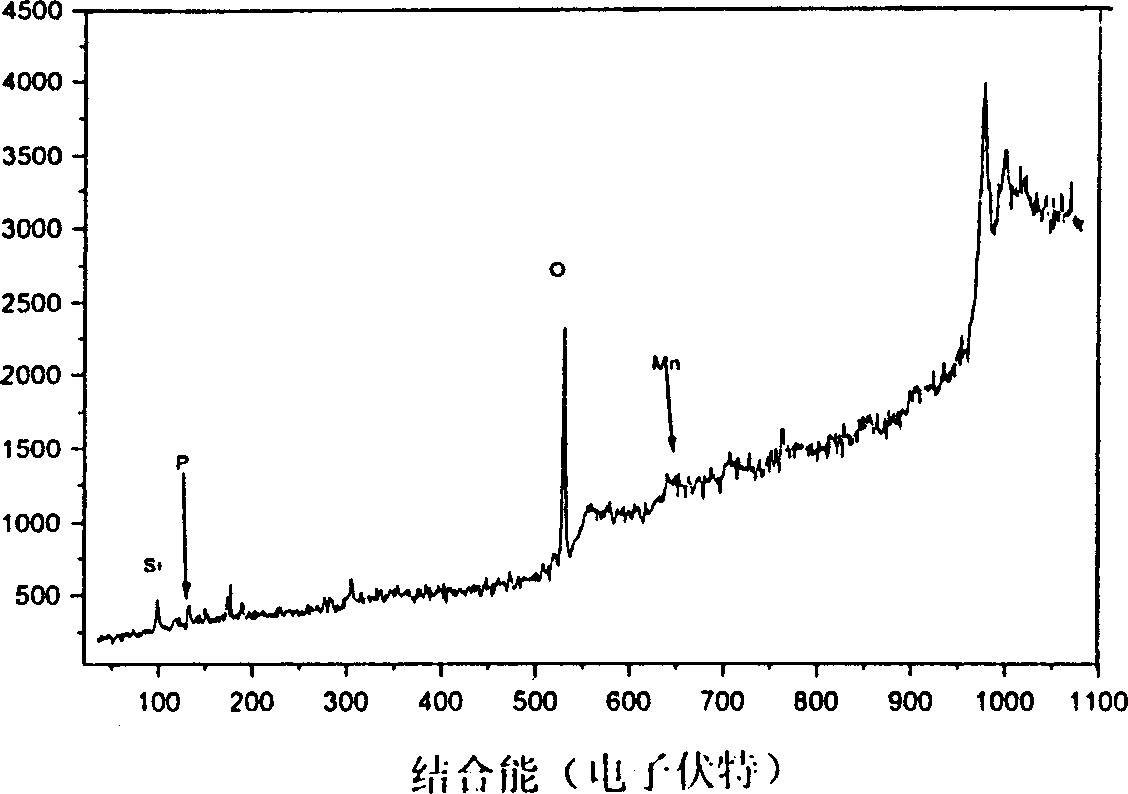

InactiveCN1236104CReduce pollutionUniform thicknessMetallic material coating processesPhosphateImpurity

A chemically transferred non-chromium Mg-alloy film is prepared through grinding said Mg-alloy, removing impurities, washing with alkali solution for defatting, washing with acidic solution for removing surfacial oxide, removing very thin oxidized film and pickling ash from its surface by fluoric acidic solution, immersing the Mg-alloy in filming solution to obtain phosphate film, and immersing in alkaline aqueous solution at 15-100 deg.C for 3-60 min for closing the pores in the film. Said filming solution is prepared from Mn salt, phosphate, fluoride and water.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Process for preparing compact magnesium oxide/hydroxyapatite nano fiber double-layer coating on surface of magnesium base

The invention discloses a process for preparing compact magnesium oxide / hydroxyapatite nano fiber double-layer coating on the surface of a magnesium base. The process includes firstly preparing porous magnesium oxide coating containing phosphorus and calcium on the surface of magnesium or magnesium alloy by the microarc oxidation technique, namely utilizing phosphorus and calcium containing water solution as electrolyte, subjecting the magnesium or magnesium alloy to microarc oxidation treatment under high voltage by means of a direct-current pulse power source, and then subjecting the porous magnesium oxide coating containing phosphorus and calcium to hydro-thermal treatment in the specific hydro-thermal environment to obtain the magnesium oxide / hydroxyapatite nano fiber double-layer coating. The magnesium oxide / hydroxyapatite nano fiber double-layer coating obtained has the structure of an inner layer (adjacent to a basal body) composed of magnesium oxide and a small amount of magnesium hydrate and being compact and a surface layer formed by nano fiber hydroxyapatite layer, and has the advantages of high bonding strength, fine biological activity and capability of improving corrosion resistance of the magnesium and magnesium alloy in body fluid evidently. Besides, no discontinuous surfaces exist between the double-layer coating and the basal body.

Owner:XI AN JIAOTONG UNIV

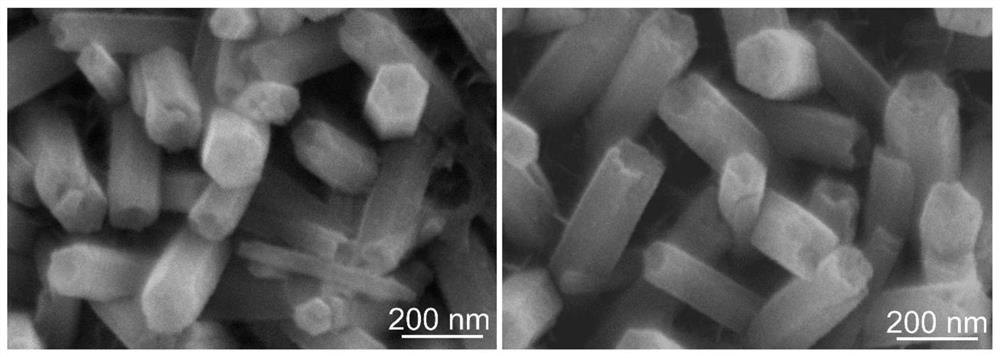

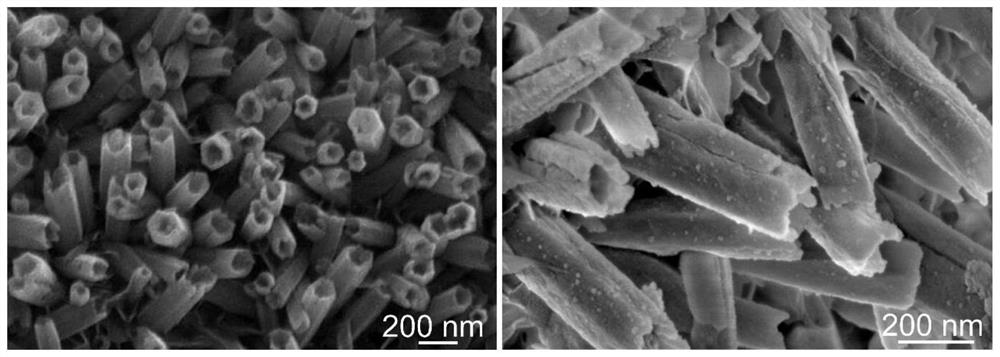

Calcium-mingled tantalum oxide nanometer bar structure biological activity coating and preparation method thereof

InactiveCN109722660ASimple ingredientsEasy to controlMetallic material coating processesProsthesisApatiteDrug biological activity

The invention discloses a calcium-mingled tantalum oxide nanometer bar structure biological activity coating and a preparation method thereof. According to the method, at first, a water solution containing hydrofluoric acid and hydrogen peroxide serves as a water heat solution, different water heat conditions are adopted for carrying out water heat treatment on a tantalum base body, then a tantalum oxide nanometer bar structure coating obtained again is subjected to water heat treatment under the calcium-contained water heat environment condition, the obtained coating microstructure is of a nanometer bar shape, the phase is tantalum pentoxide, and the nanometer bar structure coating is mingled with a calcium element. The high combination strength between the calcium-mingled nanometer bar structure coating and the base body is achieved, the calcium element separated out from the coating is increased gradually along with prolonging of soaking time, bone apatite can be induced and formedrapidly in the liquid-like environment, and the coating has good biological activity.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of refractory material and preparation method thereof

The invention discloses a refractory material and a preparation method thereof, in particular to a silicon dioxide-containing refractory material and a preparation method thereof. The refractory material prepared by the invention uses organosilicon polymer as matrix, inorganic additives as additives, and is prepared under the condition of slowly heating up. The invention can be used to prepare a series of high-temperature-resistant materials such as high-temperature equipment linings, high-temperature containers, and refractory bricks. A series of problems such as easily decomposed components.

Owner:SOUTHEAST UNIV

Technology for passivation of surface of aluminum alloy for radiator

InactiveCN104250797ASimple ingredientsEasy to controlMetallic material coating processesSodium dodecylbenzenesulfonateBoric acid

The invention discloses a technology for passivation of a surface of an aluminum alloy for a radiator. A passivation liquid used by the technology comprises 6-8g / L of nitric acid, 4-6g / L of ammonia water, 3-5g / L of boric acid, 12-14g / L of potassium permanganate, 6-8g / L of titanium sulfate, 7-9g / L of zirconium nitrate, 2-4g / L of triethanolamine, 13-14g / L of sodium dodecylbenzenesulfonate and the balance water. The technology comprises the following steps of 1, carrying out pickling on the surface of an aluminum alloy for a radiator by a pickling liquid to remove dirt and carrying out cleaning by clear water, 2, diluting the passivation liquid containing the above components according to a ratio of 1: 6-8, putting the passivation liquid into a passivation tank, adjusting a pH value to 3.5-4.5 and a temperature to 35-45 DEG C, putting the aluminum alloy for the radiator into the passivation tank, and carrying out passivation treatment for 9-11min, and 3, carrying out water washing on the passivated aluminum alloy for the radiator, carrying out drying and carrying out cooling.

Owner:无锡杨市表面处理科技有限公司

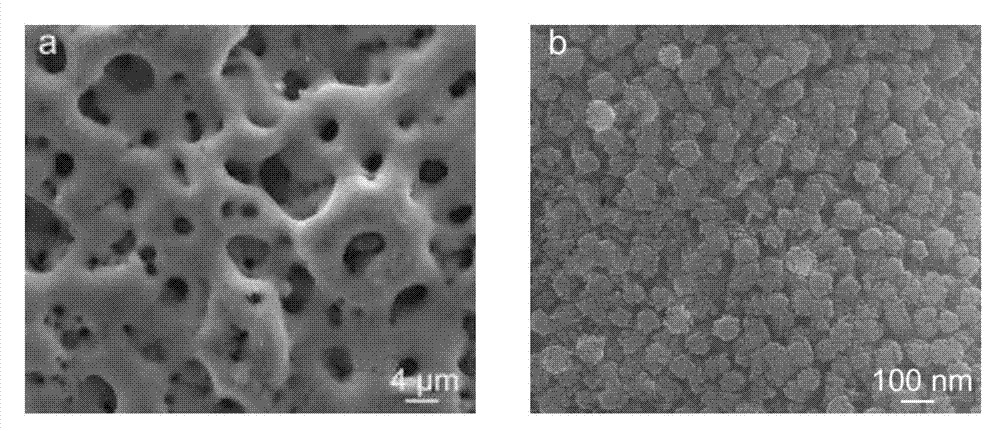

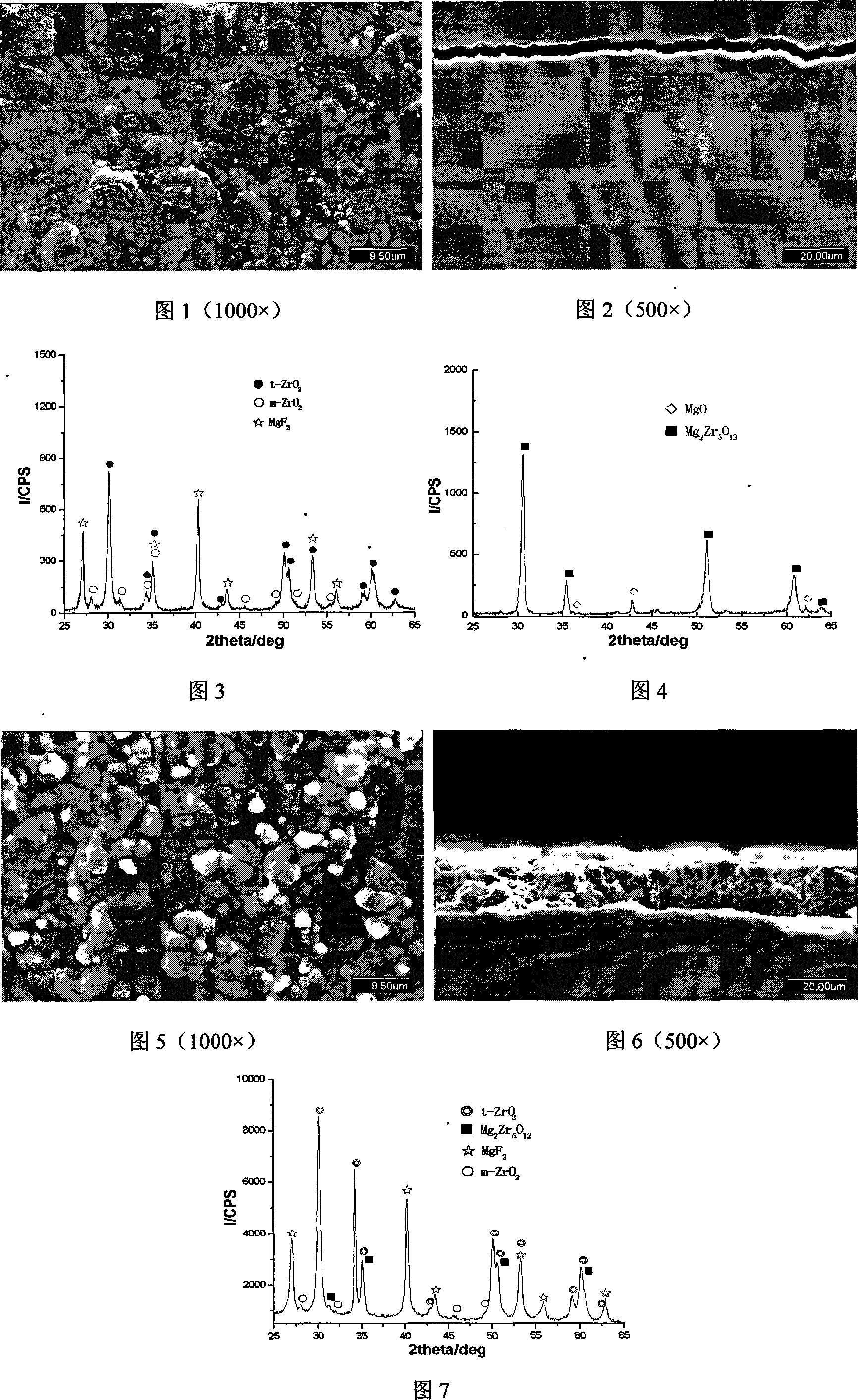

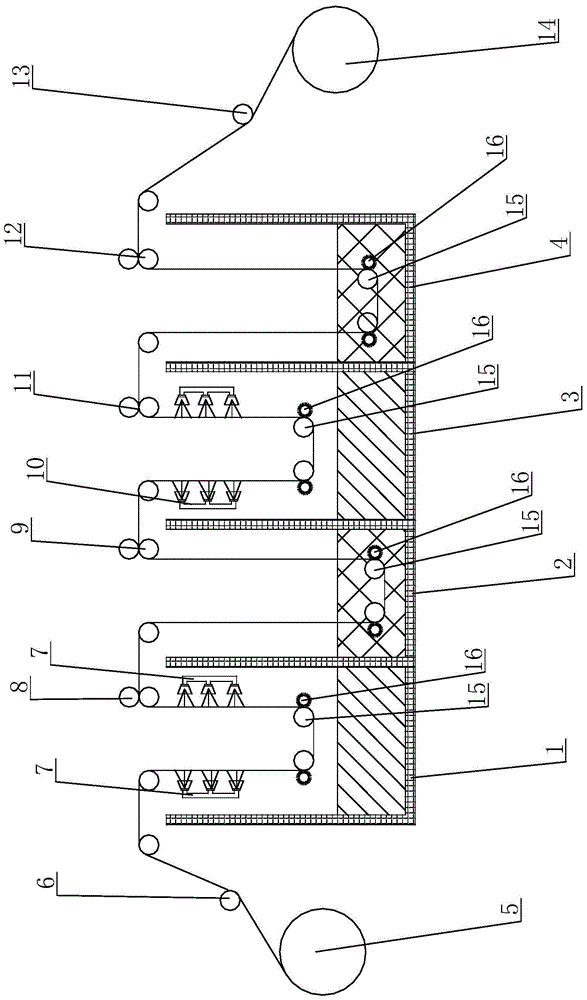

Preparation method of thermal barrier coating on surface of aluminum-magnesium alloy and composite material of alloy

ActiveCN102277606BSimple ingredientsDoes not contain easily decomposable ingredientsAnodisationElectrophoretic coatingsElectrolysisPlasma electrolytic oxidation

The invention provides a preparation method of a thermal barrier coating on the surface of an aluminum-magnesium alloy and a composite material of the alloy. The preparation method is characterized in that the thermal barrier coating on the surface of the aluminum-magnesium alloy and the composite material of the alloy is prepared by carrying out electrolytic oxidation on the surface of the aluminum-magnesium alloy and the composite material of the alloy with a silicatic and phosphatic system plasma electrolyte to form a film medium, and carrying out electrophoretic deposition on the plasma electrolytic oxidation film (the film medium) with an electrophoretic deposition electrolyte. A plasma electrolytic oxidation-electrophoresis composite ceramic layer obtained with the preparation method of the invention, which has the advantages of smooth surface, firm combination, controllable thickness, densification and less aperture, good thermal insulation and thermal shock resistance, is suitable for workpieces with various dimensions and surfaces of complicated shapes.

Owner:XIAN KANGBO NEW MATERIAL TECH

Titanium dioxide/strontium-containing fluorohydroxyapatite bioactive nanocomposite coating and its preparation method and application

ActiveCN104726921BEase of mass productionSimple and fast operationSurface reaction electrolytic coatingProsthesisSolubilityPlasma electrolytic oxidation

The invention provides a titanium dioxide / strontium and fluorine-containing hydroxyapatite bioactive nano-composite coating as well as a preparation method and an application thereof. The method comprises the following steps: firstly preparing an electrolyte containing calcium ions, strontium ions, fluorine ions and phosphate anions; and then by taking titanium or a titanium alloy as an anode and stainless steel as a cathode, directly preparing the titanium dioxide / strontium and fluorine-containing hydroxyapatite bioactive nano-composite coating on the surface of a titanium or titanium alloy substrate by virtue of a micro-arc oxidation technology. The coating consists of an inner layer combined on the surface of the substrate and a surface layer combined on the surface of the inner layer, wherein the inner layer is a titanium dioxide layer in a form of a nano crystal and the surface layer is a nano-particle strontium and fluorine-containing hydroxyapatite layer. No non-continuous interfaces are available between the coating and the substrate and the coating has high combining strength and structural stable performance; the coating is relatively small in solubility in a simulated body fluid, so that the coating is effectively implanted and used; and the nano-particle strontium and fluorine-containing hydroxyapatite layer in the surface layer can remarkably promote the osteogenic function of the cells to form new bones and inhibit bacterial adhesion and growth.

Owner:宝鸡卡斯特医疗科技有限公司

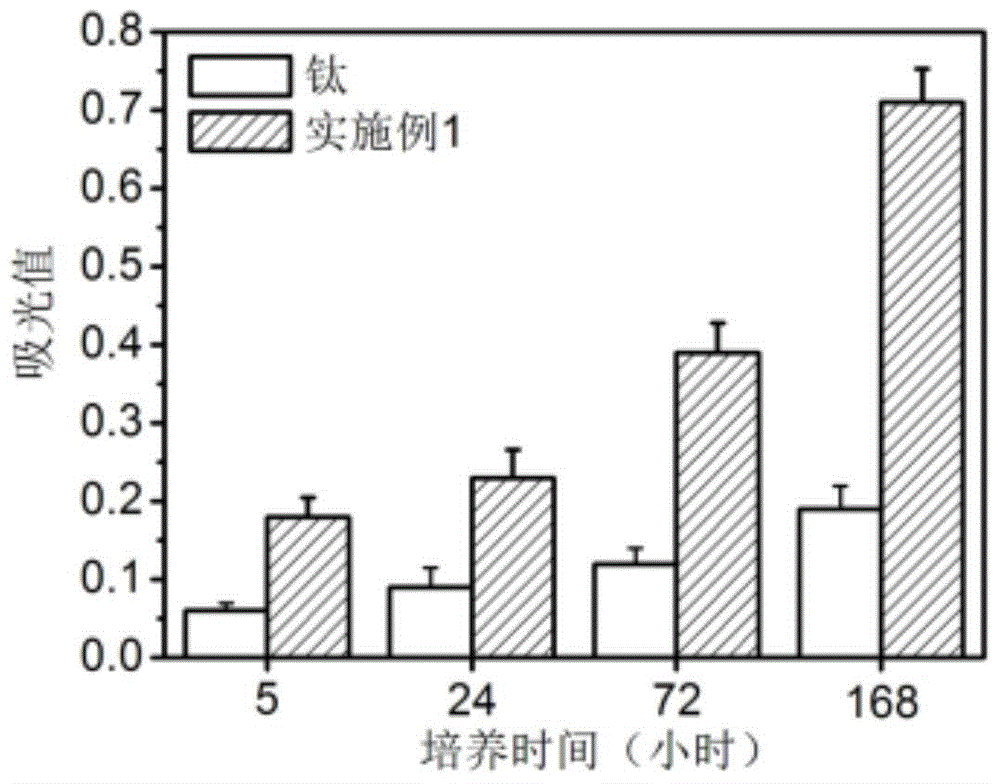

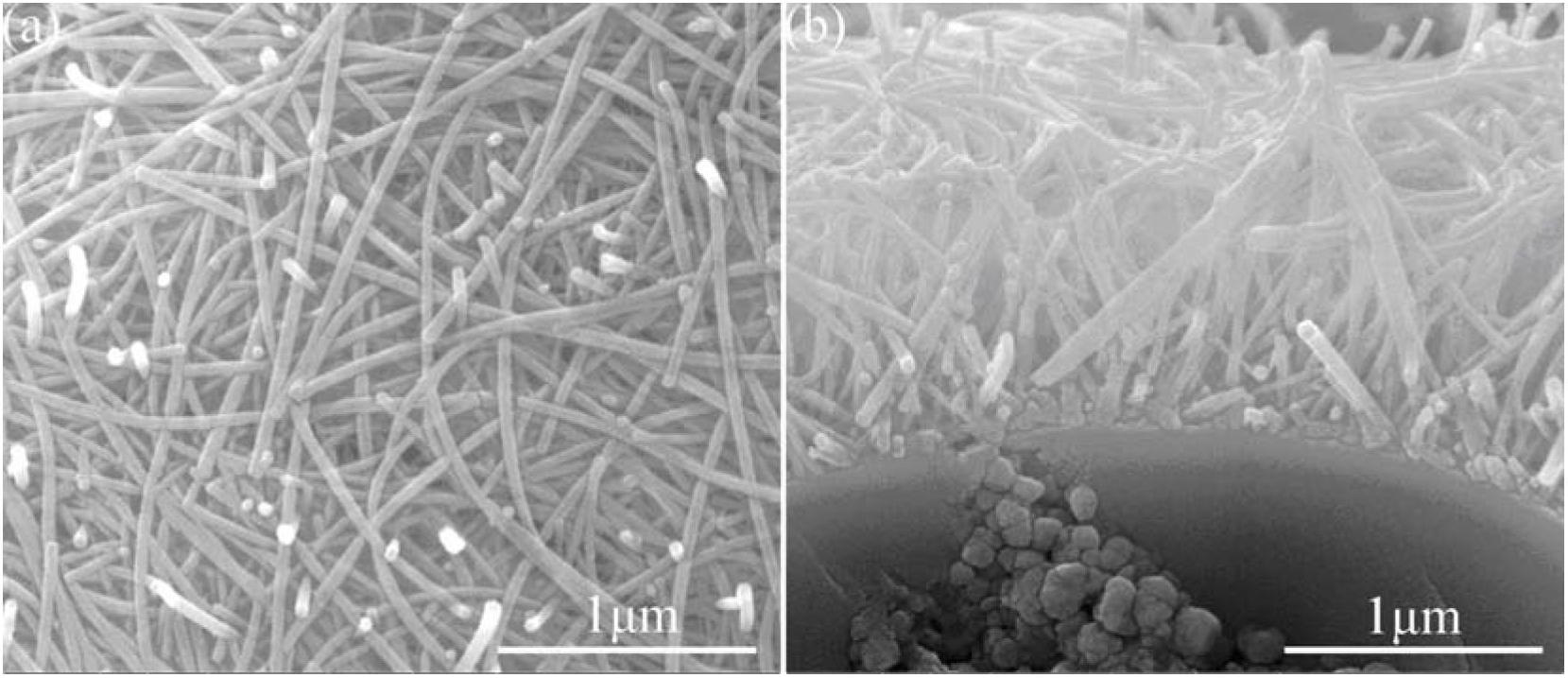

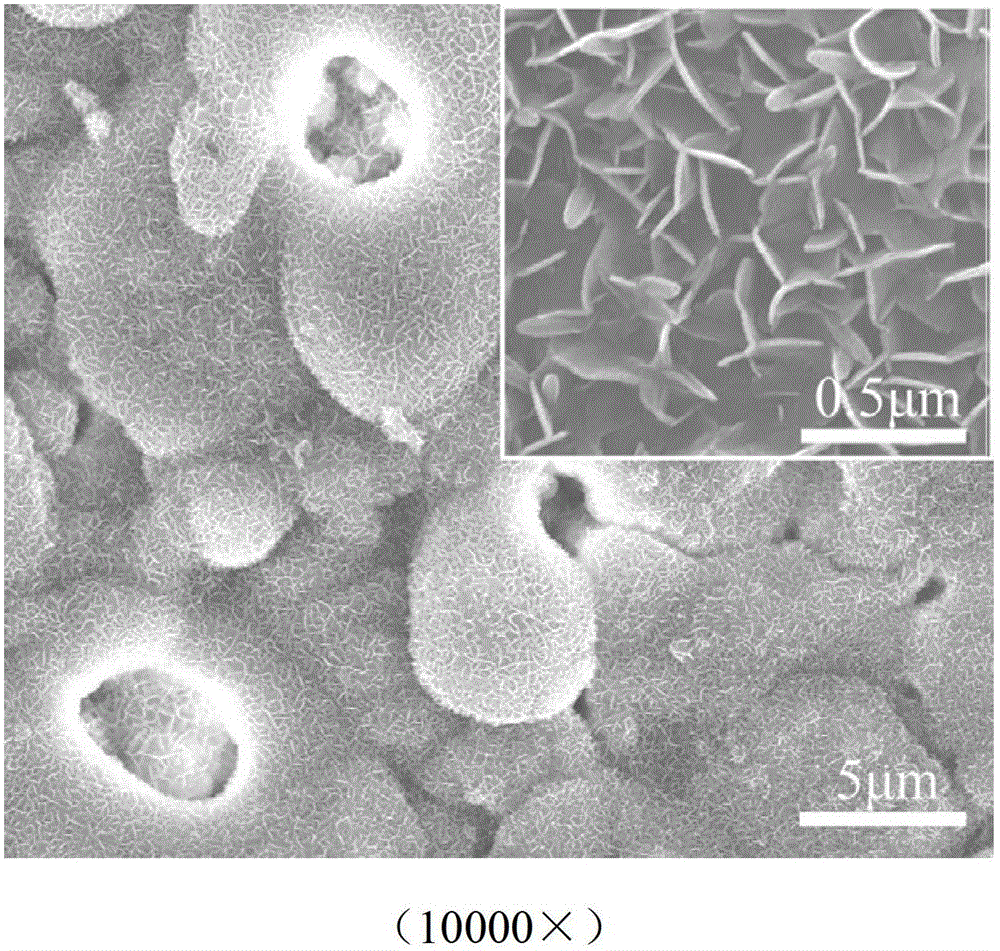

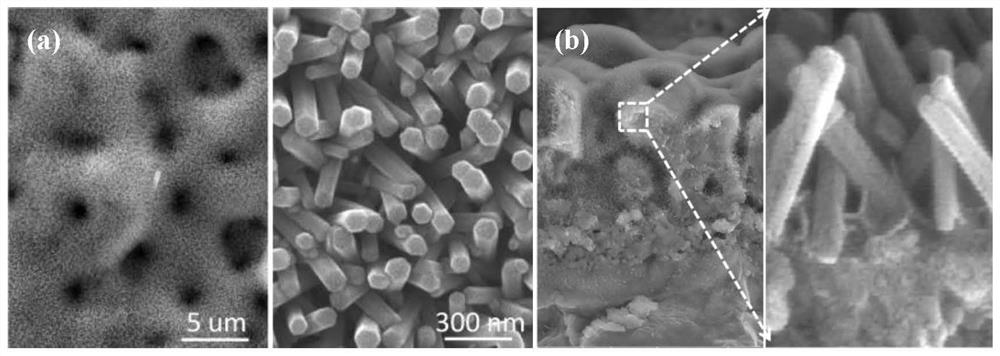

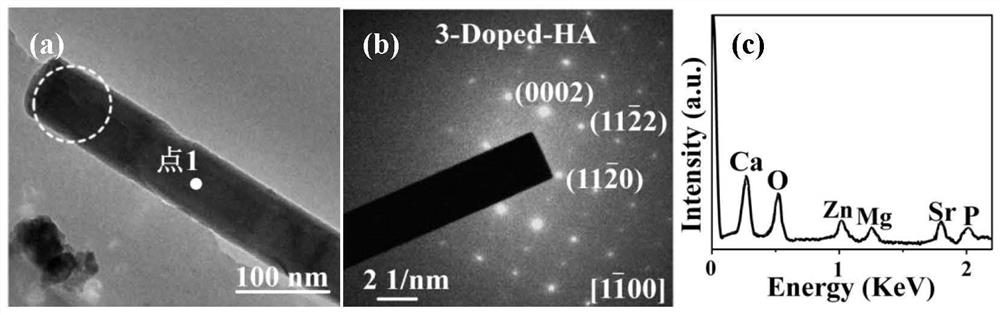

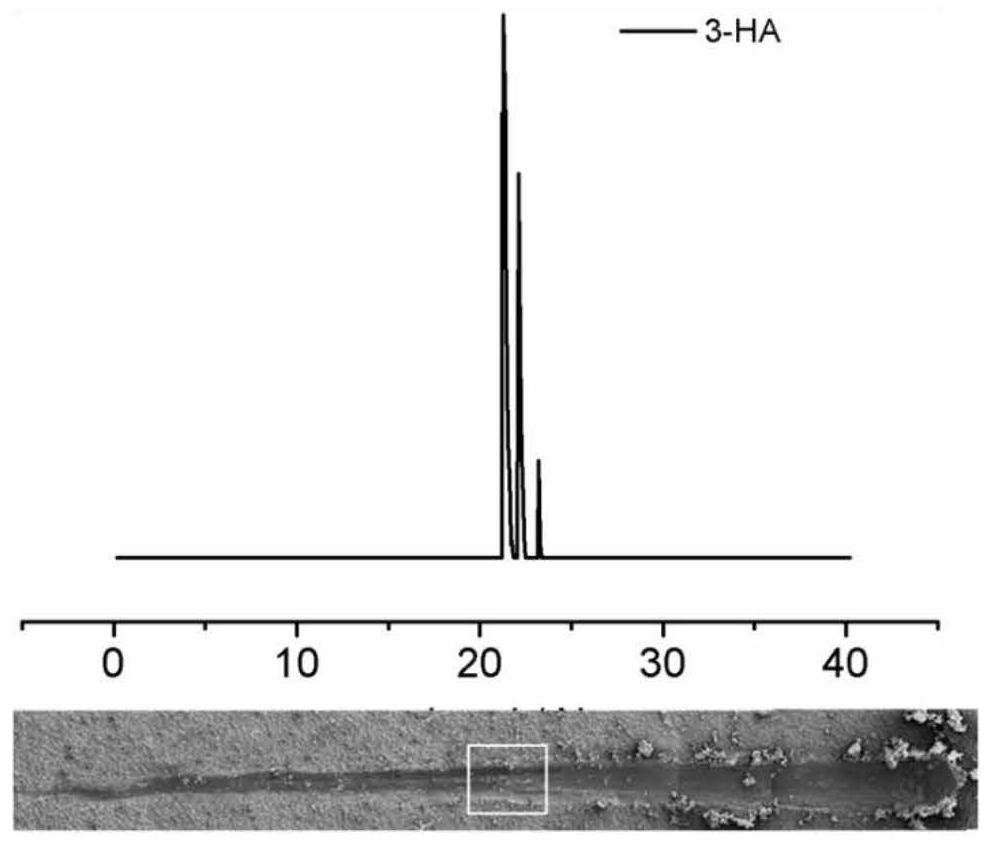

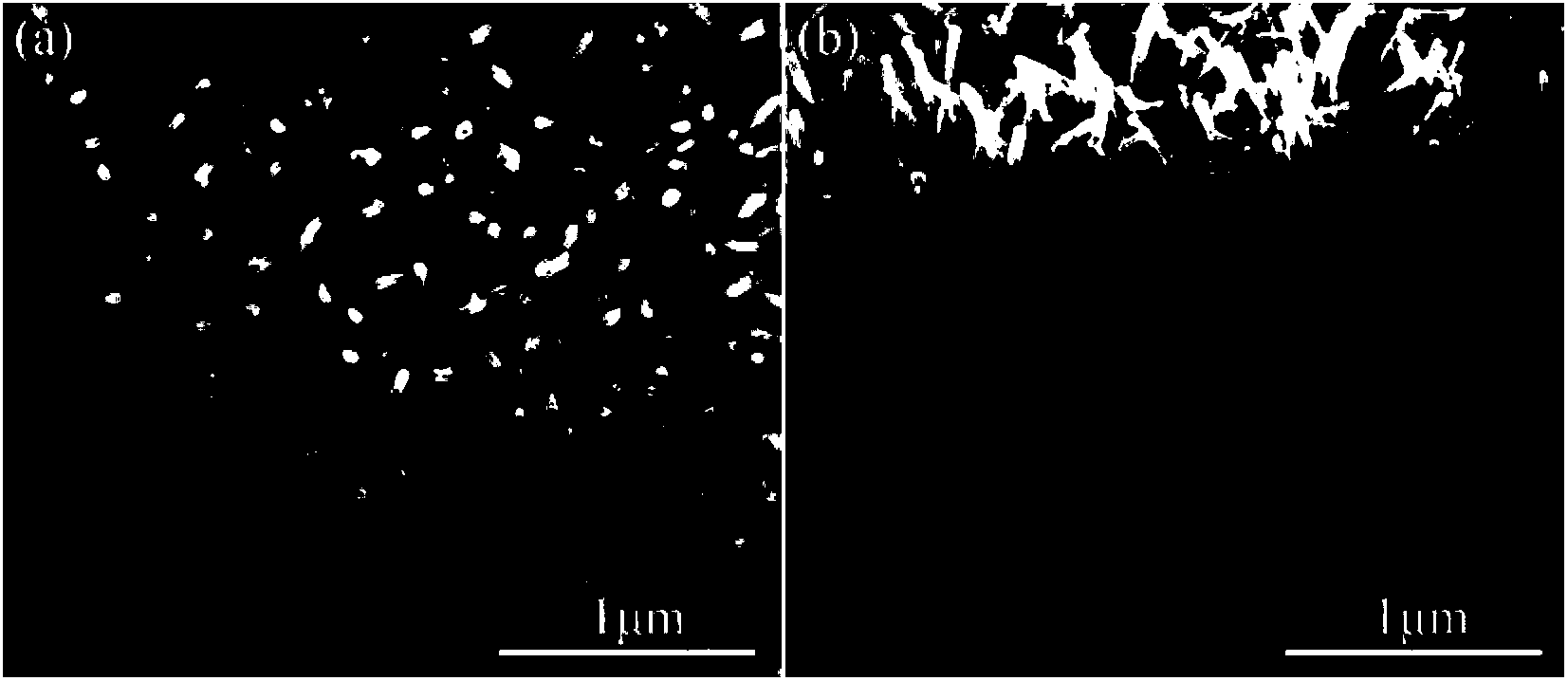

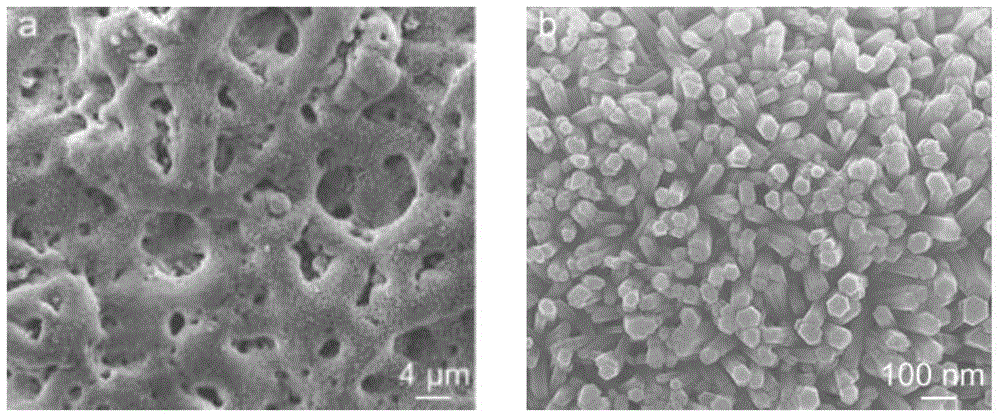

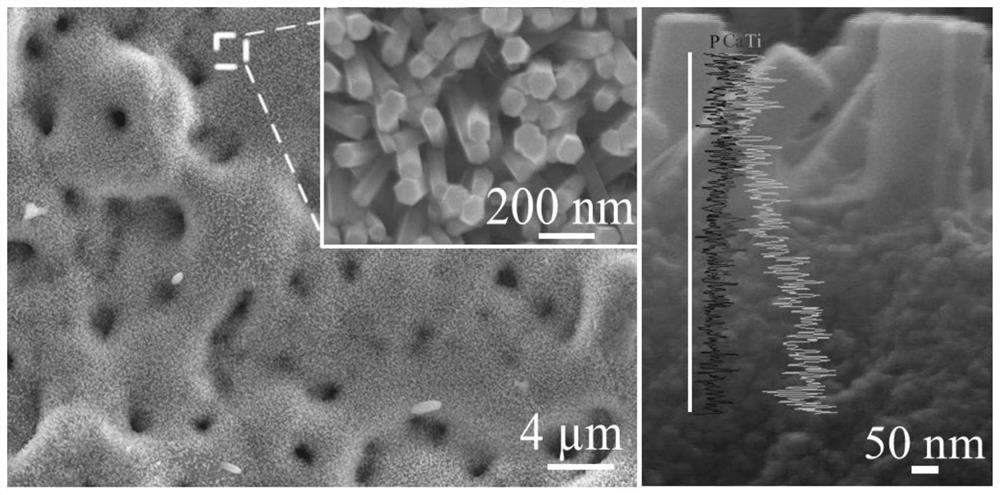

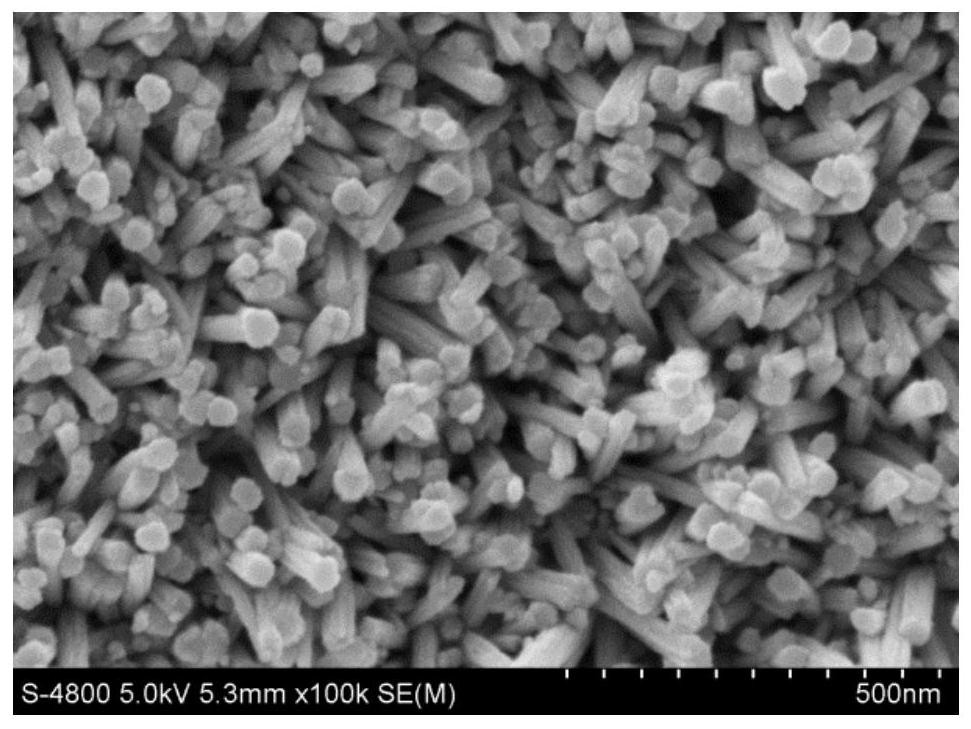

Hydroxyapatite nanorod array structured coating co-doped with multiple elements on titanium-based surface and its preparation method and application

ActiveCN109385658BSimple ingredientsEasy to controlSurface reaction electrolytic coatingTissue regenerationTitanium surfaceOsseointegration

The invention belongs to the technical field of titanium-based surface treatment, and specifically relates to a titanium-based surface multi-element co-doped hydroxyapatite nanorod array configurational coating, a preparation method and the application thereof. A micro-arc oxidation-hydrothermal treatment compound method is used, an HA nanorod array configurational coating in which three elementsof strontium, zinc and magnesium are doped is prepared on the surface of pure titanium, and co-doping of five elements such as Sr, Zn, Mg, Si and C of nanorod-like HA in a coating array is realized bycarrying out second hydrothermal treatment method on the coating. The preparation method is simple in technology and low in production cost, the obtained rod-like hydrothermal treatment gets closer to the bionic component of human bone, the coating can be quickly induced in an environment similar to a body fluid to form bone apatite, and the coating has good biological activity. The coating in combination with a micro-nano structure and biological activity elements preferably stimulates a synergetically enhanced biological effect, a novel design thought is provided for the surface modification of a metal implant, and the coating is significant for efficiently promoting osseointegration.

Owner:XI AN JIAOTONG UNIV

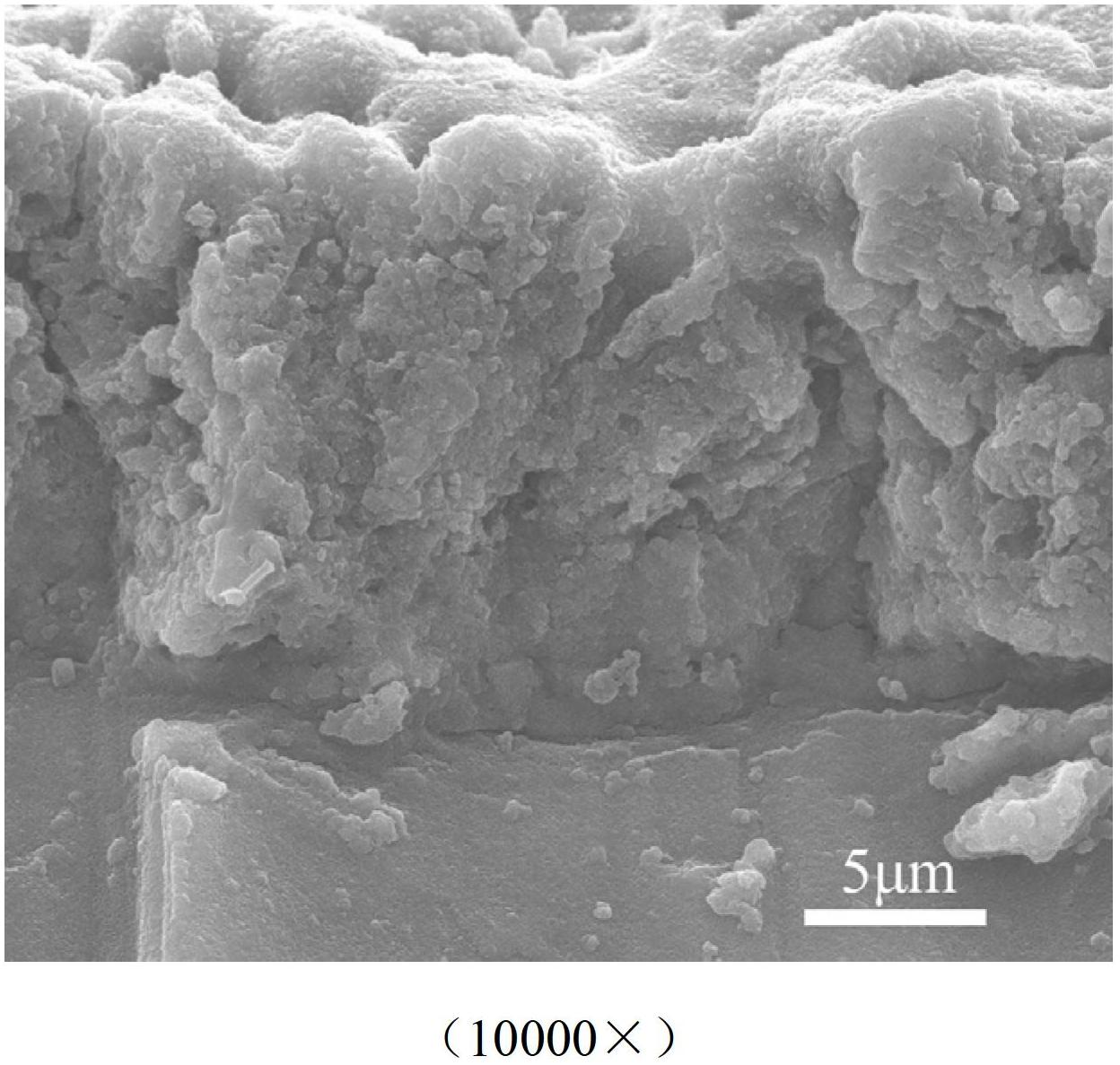

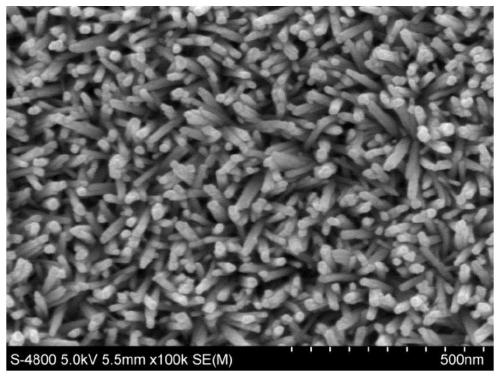

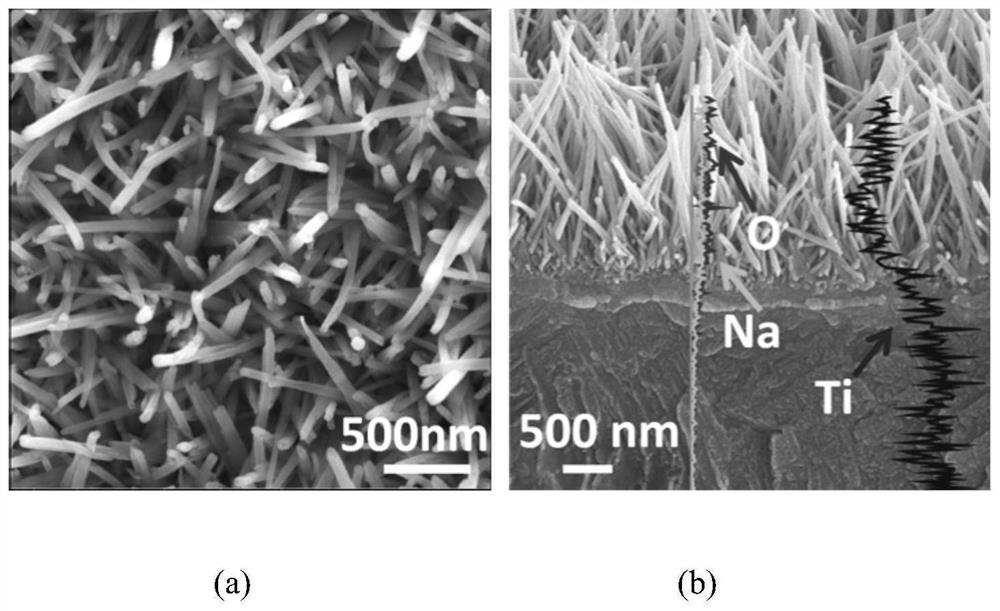

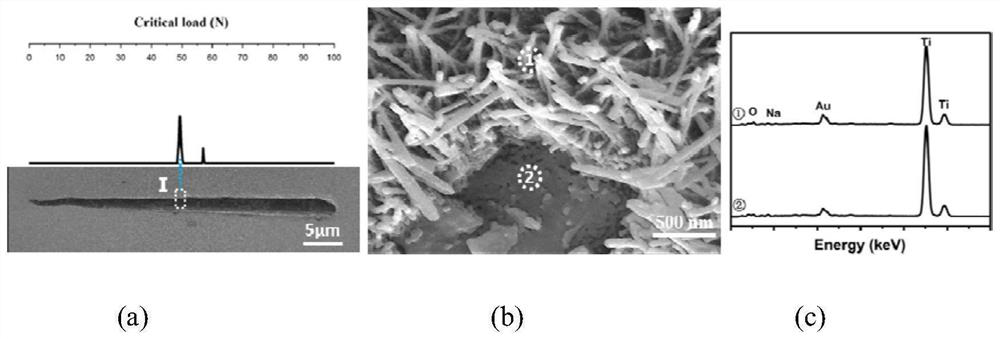

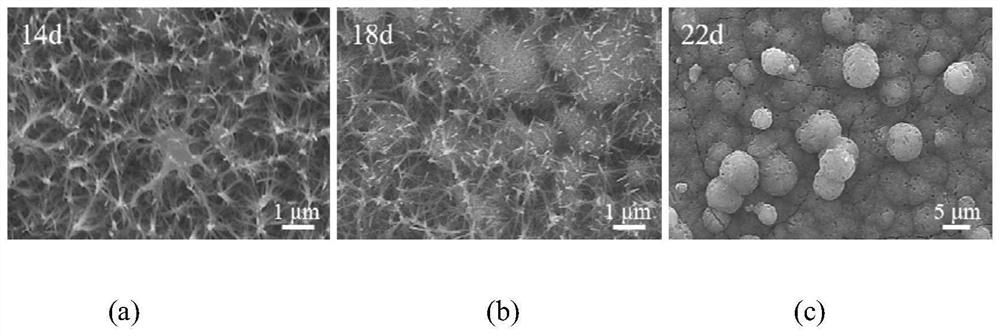

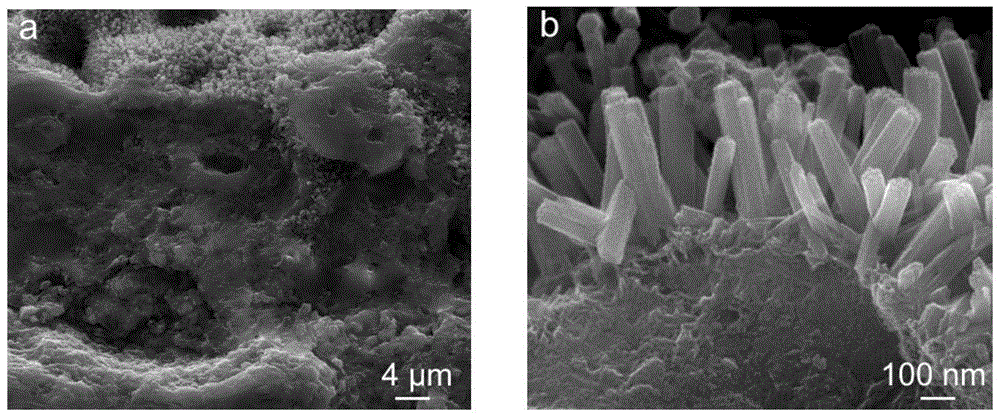

Preparation method of a 3D configuration high bonding strength sodium titanate nanofiber coating

ActiveCN112251751BConsistent buildHigh bonding strengthMaterial nanotechnologyNanomedicineTitanium surfaceNanofiber

The invention discloses a preparation method of a 3D configuration high bonding strength sodium titanate nanofiber coating. Pure titanium sheets are used as a base material, and the surface is polished and smoothed, then cleaned and dried for use; an etching solution is prepared, Put the polished titanium sheet into the etching solution to etch, then wash and dry it for use; soak the obtained pure titanium sample in a concentration of 0.5mol L ‑1 ~1.0mol·L ‑1 In the NaOH solution of 220° C. to 230° C. under the condition of hydrothermal treatment for 2 to 17 hours, a sodium titanate nanofiber coating with high bonding strength can be obtained on the titanium surface. The invention realizes the construction of three-dimensional nanofiber coatings with different geometric configurations on the surface of titanium implants through a simple and easy hydrothermal method, and the construction of the coating is uniform on each surface immersed in the solution, without dead ends and shadowing site, and a gradient 3D coating that can be used to make special bone nails that penetrate cortical bone and cancellous bone can be obtained through the combined action of liquid and gas.

Owner:XI AN JIAOTONG UNIV

Chemical nickel-plating method on magnesium alloy surface

InactiveCN1304633CReduce pollutionUniform thicknessLiquid/solution decomposition chemical coatingFluorideAqueous solution

The present invention relates to magnesium alloy surface treating technology, and is especially chemical nickel plating process for magnesium alloy. The operation process includes the following steps: activating or finishing magnesium alloy through polishing or grinding, degreasing and acid pickling with acid fluoride bearing solution at 20-60 deg.c for 0.5-5 min; pre-treating with water solution containing fluoride bearing compound, iron bearing compound and complex at 15-45 deg.c for 5-30 min; and chemically nickel plating. The said process can make chemical nickel coating with homogeneous thickness, firm combination with substrate, high corrosion resistance and metal appearance. The process of the present invention has low cost and less environmental pollution and is suitable for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation technology of porous calcium gluconate tantalite/nono-funicular hydroxylapatite bioactive coating

InactiveCN102644078BSimple ingredientsEasy to controlSuperimposed coating processPlasma electrolytic oxidationHydroxylapatite

The invention discloses a preparation technology of porous calcium gluconate tantalite / nono-funicular hydroxylapatite bioactive coating. The preparation technology comprises the following step of firstly preparing calcium and phosphorus-containing gluconate tantalite-based complex phase layer on the surface of tantalite by a micro arc oxidation technology, i.e. taking calcium and phosphorus-containing water solution as electrolyte, carrying out the micro arc oxidation treatment on the tantalum under high voltage by using a pulse power source, and carrying out the hydro-thermal treatment on the calcium and phosphorus-containing gluconate tantalite-based complex phase layer under a special hydro-thermal environment condition. The obtained coating with a double-layer structure has the following structure and performance characteristics: an inner layer (which is adjacent to a base body) is a gluconate tantalite-based complex phase layer which consists of gluconate tantalite, and a trace amount of antalum pentoxide and tantalum monoxide and is of a microporous structure in shape; and a surface layer is nono-funicular hydroxylapatite, which is inclined to or in parallel with the gluconate tantalite-based complex phase layer. No incontinuous interface exists between the coating with the double-layer structure and the base body, so that the coating is high in combining strength, and the osteolith can be quickly formed in the pseudo body fluid environment in an inducing way, so that the coating is good in biological activity.

Owner:XI AN JIAOTONG UNIV

Magnesium alloy with zinc and nickel compound plating layers and preparation method thereof

The invention discloses a magnesium alloy with zinc and nickel compound plating layers and a preparation method thereof. A zinc plating layer of the magnesium alloy is taken as a bottom layer with the width between 20 microns and 25 microns, a nickel plating layer is taken as a surface layer, and the total width of the zinc plating layer and the nickel plating layer is less than or equal to 40 microns. The method comprises the following steps: firstly, plating preliminary treatment, i.e. zinc is activated in an acid solution and then soaked in sulphate; secondly, zinc electrodeposition, i.e. after the zinc is soaked in the sulphate in the first step, the zinc layer of the magnesium alloy is electrodeposited; thirdly, nickel bright plating, i.e. the magnesium alloy which is nicely processed in the second step is brightly plated with nickel in a nickel plating solution; fourthly, sodium silicate water solution sealing. With the method, the obtained zinc plating layer is nicely combined with a base body, has uniform width and high corrosion resistance, can be taken as a protective plating layer to be singly used and can be also taken as a transition layer to carry out plating or chemical plating or other protective or decorative platings, and the nickel plating layer obtained from the zinc plating layer by plating is nicely combined with the zinc plating layer and is uniform, exquisite, bright and beautiful.

Owner:SOUTHEAST UNIV

Titanium-based surface antibacterial and bone tissue regeneration-inducing functional coating and its preparation method and application

ActiveCN104645414BEase of mass productionSimple ingredientsSurface reaction electrolytic coatingProsthesisElectrolytic agentMicro arc oxidation

The invention provides a titanium-based surface antibacterial and bone tissue regeneration induced functional coating as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly preparing an electrolyte, taking titanium or a titanium alloy as an anode and taking stainless steel as a cathode, preparing a porous TiO2 coating containing calcium, phosphorus and strontium by adopting a micro-arc oxidation technology, then sequentially performing hydro-thermal treatment by virtue of a fluorine-containing solution, and also loading human bone morphogenetic protein-2 to finally obtain a target coating disclosed by the invention, wherein the coating consists of an inner layer which is bonded on the surface of a matrix and a surface layer which is bonded on the surface of the inner layer, the inner layer is a porous TiO2 layer containing calcium, phosphorus and strontium, and the surface layer is a three-dimensional nano-fibrous hydroxyapatite layer which is loaded with human bone morphogenetic protein-2 and contains strontium and fluorine. No non-continuous interface is formed between the coating and the matrix, so that the coating provided by the invention has relatively good bonding strength and structure stability performance, also has good antibacterial and bone tissue regeneration inducing functions, and can be used for significantly promoting the osteogenic function of cells, promoting new bone formation and inhibiting the adhesion and growth of bacteria.

Owner:宝鸡卡斯特医疗科技有限公司

Zinc titanate-titanium oxide composite antibacterial coating on titanium surface and preparation method thereof

ActiveCN105648497BSimple ingredientsRaw materials are easy to getElectrolytic inorganic material coatingSurface reaction electrolytic coatingElectrolytic agentTitanium surface

The invention discloses a zinc titanate-titanium oxide composite antibacterial coating on the surface of titanium and a preparation method of the zinc titanate-titanium oxide composite antibacterial coating and belongs to the technical field of titanium-based surface treatment. The preparation method comprises the steps that a combination solution of a (CH3COO)2Zn solution and a beta-C3H7Na2O6P solution serves as an electrolyte; and a metallic titanium sheet serves as the anode, stainless steel serves as the cathode, the metallic titanium sheet and the stainless steel are placed into the electrolyte, the metallic titanium sheet is treated through a micro-arc oxidation process, and the zinc titanate-titanium oxide composite antibacterial coating is prepared on the surface of the titanium sheet. According to the preparation method, raw materials are easy to obtained, operation is easy, control is easy, and the stability is good; and the antibacterial coating prepared through the preparation method has high biological activity as well as antibacterial property, no discontinuous interface exists between the antibacterial coating and a basal body, and high combination strength is achieved.

Owner:XI AN JIAOTONG UNIV

A nanorod array coating with thermal control immunity and anti-oxidation functions, its preparation method and application

ActiveCN112169023BProcess stabilityThe process is simple and easy to controlSurface reaction electrolytic coatingPharmaceutical delivery mechanismMicro arc oxidationOxidation resistant

The invention discloses a nanorod arrayed coating with functions of thermal control immunity and anti-oxidation, a preparation method and application thereof, and belongs to the technical field of biomedical materials. Firstly, a porous titanium dioxide coating containing phosphorus and calcium is prepared on the surface of titanium or its alloys by micro-arc oxidation, and then hydrothermal treatment is used to grow hydroxyapatite nanorods in situ on the porous titanium dioxide coating containing phosphorus and calcium. Finally, polydopamine-coated hydroxyapatite nanorod arrays were prepared by oxidative self-polymerization method, and finally a nanorod array coating with thermal control immunity and anti-oxidation functions was obtained. The process is stable and controllable; the surface layer of the prepared biomedical material has dual functions of anti-oxidation and light and heat; as an implant, it can heal and regenerate bone tissue, and avoid coating caused by poor membrane / substrate binding force. Detachment of the layer and the occurrence of side effects such as osteolysis or excessive inflammation induced by it.

Owner:陕西佳诺博奥生物科技有限公司

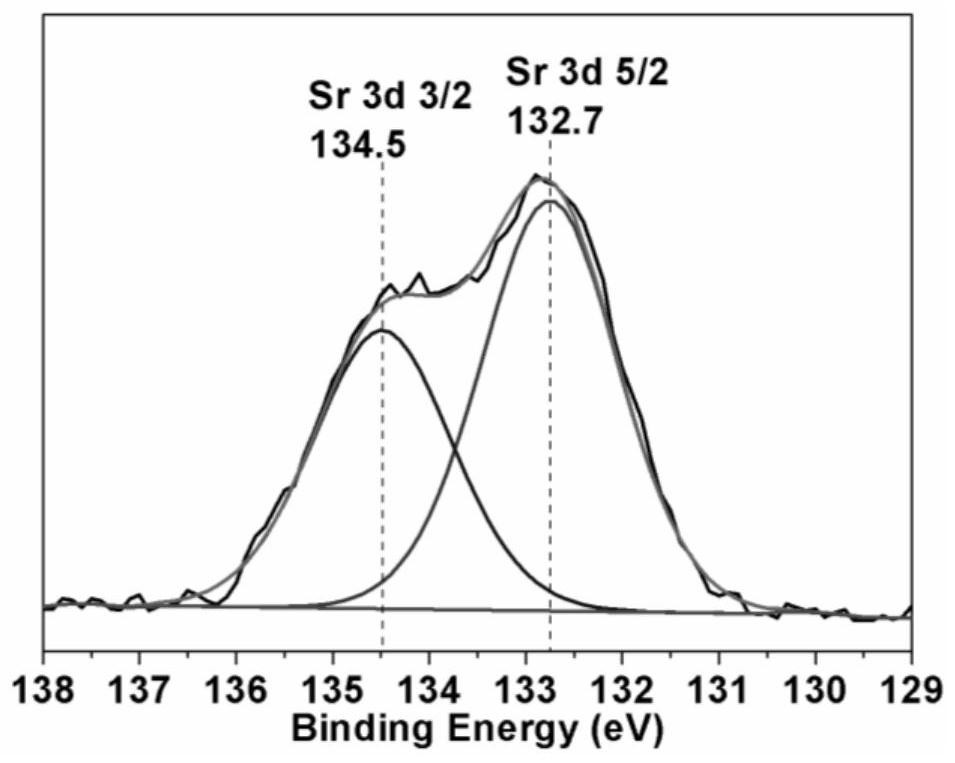

Preparation method of strontium-doped tantalum oxide nanorod structure bioactive coating

ActiveCN108042846BSimple ingredientsEasy to controlMetallic material coating processesTissue regenerationBioactive coatingHydrogen peroxide

The invention discloses a preparation process of a tantalum surface strontium doped tantalum oxide nanorod structure bioactive coating. Firstly, an aqueous solution containing hydrofluoric acid, nitric acid and hydrogen peroxide is taken as a hydro-thermal solution, a tantalum matrix is subjected to hydro-thermal treatment under different hydro-thermal conditions, then the obtained tantalum oxidenanorod structure coating is subjected to hydro-thermal treatment again under the strontium-containing hydro-thermal environment condition, a microstructure of the obtained coating takes the shape ofa nanorod, the physical phase is tantalum pentoxide, the strontium element is doped in the nanorod structure coating, the bonding strength between the strontium doped nanorod structure coating and thematrix is high, the surface roughness of the obtained coating is relatively small, the precipitation of the strontium element from the coating shows the rule that the strontium element is precipitated fast firstly and then precipitated slowly, bone apatite is rapidly induced to be formed in the body-fluid-like environment, and the coating is excellent in bioactivity.

Owner:SHAANXI UNIV OF SCI & TECH

Nanorod array textured coating with anti-oxidation and self-generating oxygen functions on titanium-based surface, its preparation method and application

ActiveCN112791232BEnhanced interface bindingSimple ingredientsAnodisationProsthesisMicro arc oxidationOxidation resistant

The invention discloses a nano-rod array structured coating with a titanium-based surface having both anti-oxidation and self-generating oxygen functions, a preparation method and an application thereof. Firstly, a porous titanium dioxide coating containing phosphorus and calcium was prepared on the surface of titanium or its alloys by micro-arc oxidation, and then a hydroxyapatite nanorod textured coating was grown in situ by hydrothermal treatment, and then polymer was prepared by oxidative self-polymerization. The dopamine-coated hydroxyapatite nanorod array is finally obtained by polydopamine adsorption of metal ions and hydrothermal method to obtain a biomedical material with both anti-oxidation and self-generating oxygen coating. The process of the invention is stable and controllable; the prepared coating surface has dual functions of anti-oxidation and self-generating oxygen at the same time; as an implant, it can regulate the bad bone microenvironment under the condition of RA, promote the healing and regeneration of bone tissue, Avoid the failure of the implant due to the poor bone microenvironment, the peeling of the coating induced by the poor membrane / base binding force, and the side effects such as osteolysis or excessive inflammation induced by it.

Owner:陕西佳诺博奥生物科技有限公司

Element of arc oxidation electrolyte of environmental protection type magnesium alloy, and method of element of arc oxidation

InactiveCN100510197CNo pollution in the processLess strong alkaliAnodisationAluminateMicro arc oxidation

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A treatment process and device for aluminum-plastic composite film for anti-hydrofluoric acid corrosion

The invention discloses a treating process and a treating device of a hydrofluoric acid corrosion resistant aluminum-plastic composite film. The treating process comprises the following steps: (1) removing oil from the bright surface of aluminum foil; (2) leaching the bright surface of the aluminum foil to remove alkali; (3) performing hydrofluoric acid treatment on the bright surface of the aluminum foil: leaching the bright surface of the aluminum foil with hot hydrofluoric acid water solution, and thus forming an aluminum fluoride salt conversion film under certain etching action generated by the strongly acid solution on the surface of the aluminum foil; (4) dipping with cold water; and (5) bonding the composite film: bonding a polypropylene film and the treated bright surface of the aluminum foil with an adhesive, so as to form a hydrofluoric acid resistant aluminum-plastic composite film. The treating fluid of the treating process of the hydrofluoric acid corrosion resistant aluminum-plastic composite film does not contain hexavalent chromium and has the advantages of environmental friendliness, high film-forming speed, simple process, uniformity of the film, strong corrosion resistance, little environmental pollution and low use cost, and additionally, the hydrofluoric acid resistant performance of aluminum-plastic composite materials can meet the requirements.

Owner:无锡市华泰医药包装有限公司

Chemical treatment method for aluminum alloy surface

InactiveCN100497734CSimple ingredientsEasy to controlMetallic material coating processesChemical treatmentFine chemical

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com